Walnut oligopeptide, and preparation technology and use thereof

A technology of walnut oligopeptide and content, applied in the biological field, can solve problems such as difficulty and low utilization rate of walnut protein, and achieve the effect of relieving brain fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

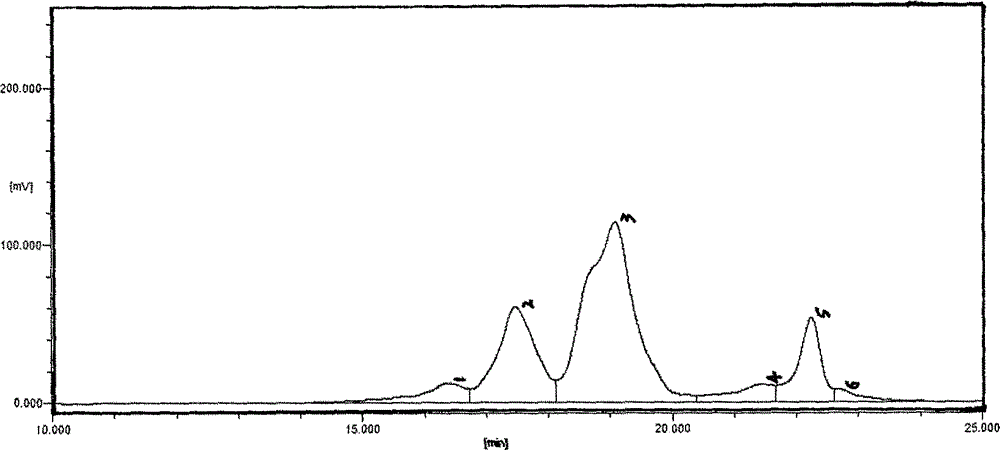

Image

Examples

Embodiment 1

[0040] Peptide powder obtained by a single enzymatic hydrolysis method: divide 300kg of cold-pressed and degreased walnut meal into three equal parts, the first equal part of walnut meal (recorded as A) is mixed with water at a weight ratio of 1:10, and the pH is adjusted to 10 Extract at room temperature for 2 hours; after the extraction is completed, filter and filter the residue for secondary extraction, pour the filtrate into the second aliquot of walnut meal (recorded as B), adjust the pH to 10 and extract at room temperature for 2 hours; after B completes the first extraction, The filtrate is ready for use, and the filter residue continues to be extracted for the second time; after A completes the second extraction, the filter residue is discarded, and the filtrate is poured into the third equal portion of walnut meal (recorded as C), and the pH is adjusted to 10 and extracted at room temperature for 2 hours; B is completed After the second extraction, the filter residue ...

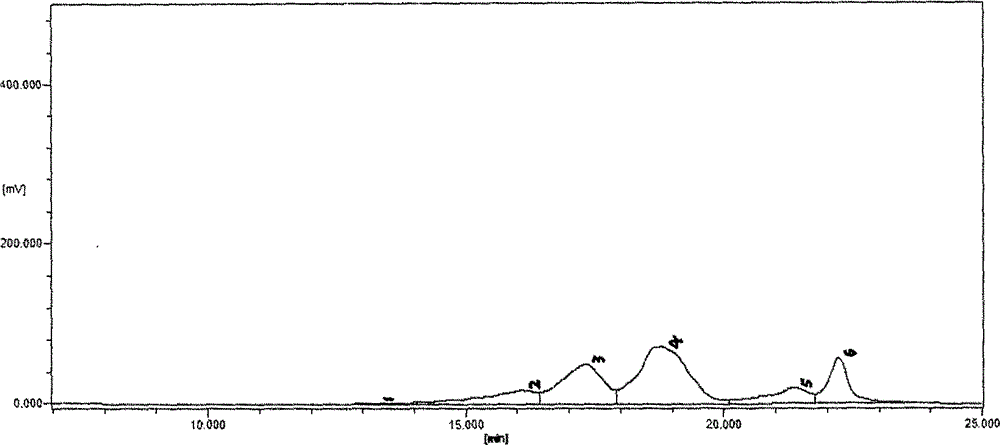

Embodiment 2

[0043] Peptide powder obtained by a single enzymatic hydrolysis method: mix 100 kg of cold-pressed degreased walnut meal with water at a weight ratio of 1:10, adjust the pH to 9.5, extract at room temperature twice, each time for 2 hours, and combine the two alkaline extracts, Centrifugal filtration, adjust the pH of the filtrate to 5, let it stand for 6 hours, discard the supernatant, and finally add water with a volume ratio of 1:10 to the precipitate, and heat to 50°C, adjust the pH value to neutral, add 1kg of papain (enzyme activity: 500,000 u / g), stirred for 5 hours, boiled to inactivate for 30 minutes, centrifuged, and the supernatant was the proteolysis solution. The proteolysis solution was filtered with a microfiltration membrane with a pore size of 0.1 μm, and the permeate was treated with a 5000 Dalton ultrafiltration membrane, and the retentate was concentrated at 80°C to a solid content of 4.1%, then spray-dried, and the inlet temperature was 140°C, the outlet te...

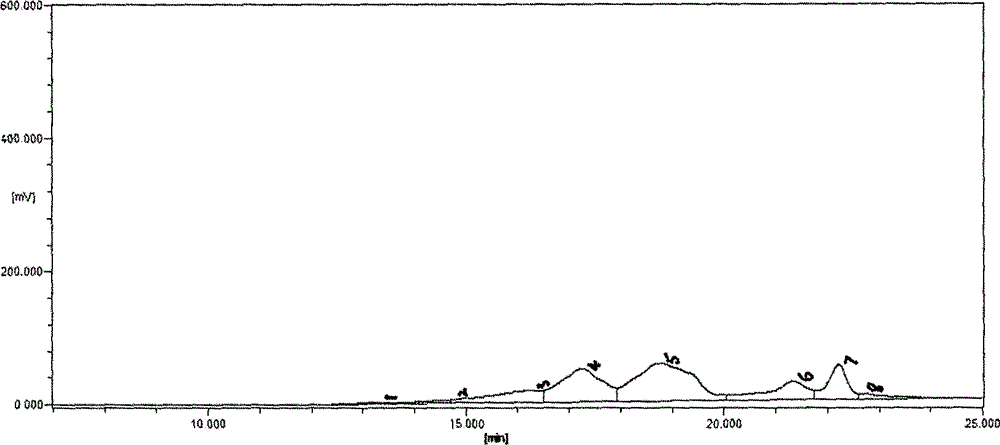

Embodiment 3

[0046] Peptide powder obtained by a single enzymatic hydrolysis method: mix 100 kg of cold-pressed degreased walnut meal with water at a weight ratio of 1:10, adjust the pH to 9.5, extract at room temperature twice, each time for 2 hours, and combine the two alkaline extracts, Centrifugal filtration, adjust the pH of the filtrate to 5, let it stand for 6 hours, discard the supernatant, and finally add water with a volume ratio of 1:10 to the precipitate, and heat to 55°C, adjust the pH value to neutral, add 1kg bromelain (enzyme activity is 1 million u / g), stirred for 6 hours, boiled to inactivate for 30 minutes, centrifuged, and the supernatant was the proteolysis solution. The proteolysis solution is filtered with a microfiltration membrane with a pore size of 0.1 μm. After the permeate is treated with a 5000 Dalton ultrafiltration membrane, the retentate is concentrated at 80°C to a solid content of 3.7%, and then spray-dried. The inlet temperature is 140°C, the outlet temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com