Method of preparing water chestnut juice through composite enzymolysis

A compound enzymatic hydrolysis and compound enzyme technology, which is applied in the field of compound enzymatic hydrolysis to prepare horseshoe juice, can solve the problems of low horseshoe juice yield and product instability, and achieve the effect of improving the juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

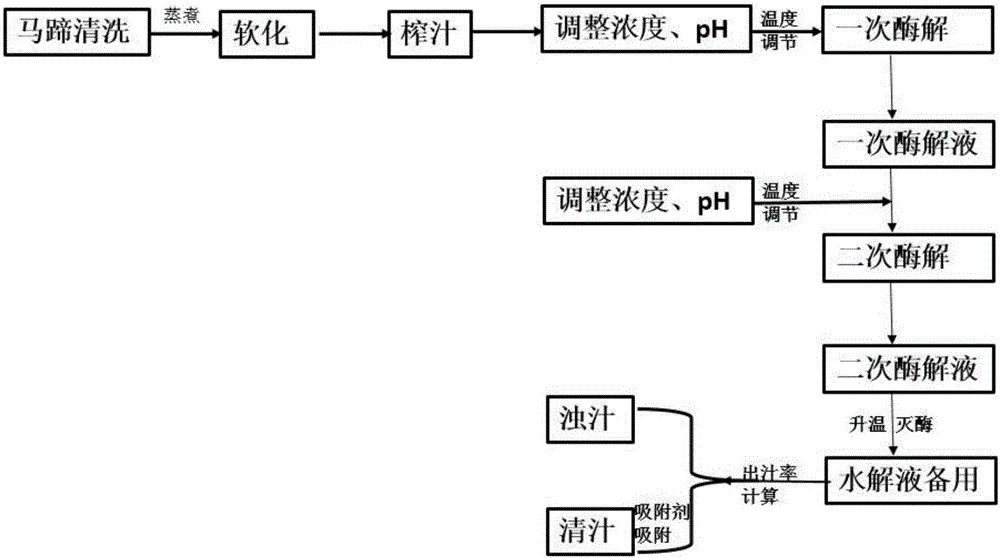

Method used

Image

Examples

Embodiment 1

[0035] A process research method of compound enzymolysis water chestnut juice, the steps are as follows:

[0036] (1) Wash 1 kg of horseshoe, cook for 15-20 minutes, soften, crush, add water according to the weight ratio of horseshoe and water 1:2 to make slurry.

[0037] (2) The first enzymatic hydrolysis: add water to adjust the concentration of the slurry, so that the ratio of the weight of the horseshoe to water is 1:2, and then use food-grade citric acid or dilute hydrochloric acid to adjust the pH value to make the pH 4.0-5.0, and then Add compound enzyme I, enzymolysis time is 30-45min, enzymolysis temperature is 35-40°C, temperature can be adjusted by water bath heater, enzymolysis is carried out under slow stirring state, and enzymolysis solution is obtained.

[0038] Wherein, compound enzyme I is composed of cellulase, pectinase, amylase, and glucoamylase, wherein the enzyme activity ratio is 2.5:2.5:1.5:1 respectively, and the enzyme amount of cellulase is 25000U / kg...

Embodiment 2

[0044] A method for compound enzymatic hydrolysis of water chestnut juice, the steps are as follows:

[0045] (1) Wash 2kg of horseshoe, cook for 30 minutes, soften, crush, add water according to the weight ratio of horseshoe and water 1:2 to make slurry.

[0046] (2) The first enzymatic hydrolysis: add water to adjust the concentration of the slurry, so that the ratio of horseshoe raw materials and water is 1:2, adjust the pH value to 4.0, add compound enzyme I, enzymolysis time 60min, enzymolysis temperature 30°C; compound Enzyme I is composed of cellulase, pectinase, amylase and glucoamylase with an enzyme activity ratio of 4.5:5.5:2:3.5, and the amount of amylase added is 8000U / kg (horseshoe raw material).

[0047] (3) The second enzymolysis: add water to adjust the concentration of the first enzymolysis solution, so that the ratio of the water chestnut raw material to the enzymolysis solution obtained after the first enzymolysis is 1:4, and adjust the pH so that the pH va...

Embodiment 3

[0051] A method for compound enzymatic hydrolysis of water chestnut juice, the steps are as follows:

[0052] (1) Wash the horseshoe, cook for 30 minutes, soften, crush, and add water to make a slurry.

[0053] (2) The first enzymatic hydrolysis: add water to adjust the concentration of the slurry, so that the ratio of horseshoe raw materials and water is 1:2, adjust the pH value to 6.0, add compound enzyme I, enzymolysis time 30min, enzymolysis temperature 40°C; compound Enzyme I is composed of cellulase, pectinase, amylase and glucoamylase with an enzyme activity ratio of 5.5:4.5:4:2.5. The amount of enzyme added is 8000-48000U / kg (horseshoe raw material), the amount of amylase added is 8000-48000U / kg (horseshoe raw material), and the amount of glucoamylase added is 8000-48000U / kg (horseshoe raw material).

[0054] (3) The second enzymolysis: add water to adjust the concentration of the first enzymolysis solution, so that the ratio of the water chestnut raw material to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com