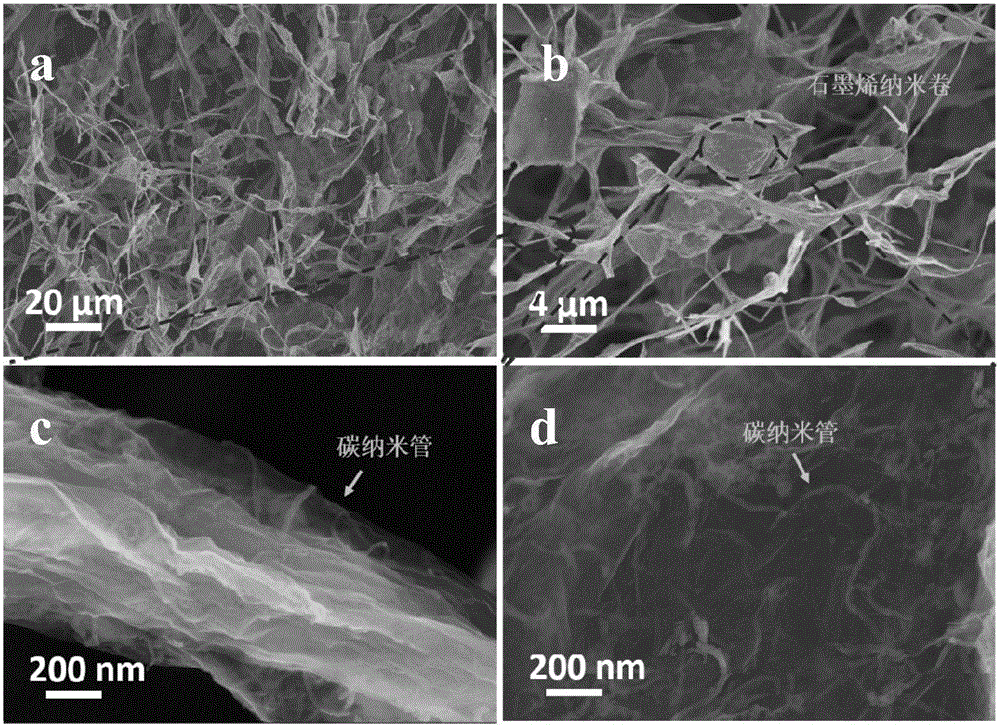

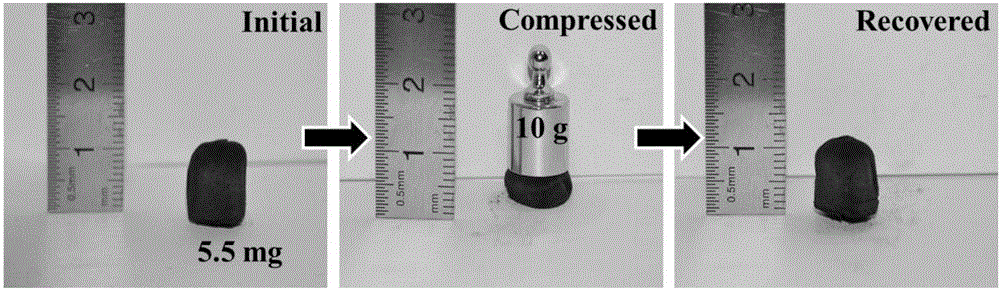

Graphene roll/carbon nanotube composite aerogel material, preparation and application thereof

A carbon nanotube composite, graphene roll technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problem that graphene performance cannot be fully utilized, and achieve good deformation adaptability, good mechanical properties, and inhibit stacking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Disperse graphite oxide in deionized water, and obtain 4mg mL by ultrasonic -1 Stable dispersed graphene oxide dispersion;

[0034] (2) Disperse the acidified carbon nanotubes in deionized water, and obtain 1mg mL by ultrasonic -1 Stable dispersed graphene oxide dispersion;

[0035] (3) 10mL 4mg mL -1 Graphene oxide dispersion and 10mL 1mg mL -1 The acidified carbon nanotube dispersion is mixed, and ultrasonicated for a period of time to form a uniform dispersion;

[0036] (4) Place the mixed solution of step (3) gained in the mold and freeze in liquid nitrogen for 20min;

[0037] (5) freeze-dry the composite material obtained in step (4) in a freeze-drying machine, the freeze-drying temperature is -30°C, the vacuum is 10Pa, and the freeze-drying time is 20h to form a graphene oxide roll-carbon nanotube composite gas gel;

[0038](6) Carry out high-temperature carbonization of the airgel obtained in step (5) in a nitrogen atmosphere, the carbonization temperat...

Embodiment 2

[0040] (1) Disperse graphite oxide in deionized water, and obtain 8mg mL by ultrasonic -1 Stable dispersed graphene oxide dispersion;

[0041] (2) Disperse the acidified carbon nanotubes in deionized water, and obtain 1mg mL by ultrasonic -1 Stable dispersed graphene oxide dispersion;

[0042] (3) 10mL 4mg mL -1 Graphene oxide dispersion and 10mL 1mg mL -1 The acidified carbon nanotube dispersion is mixed, and ultrasonicated for a period of time to form a uniform dispersion;

[0043] (4) Place the mixed solution of step (3) gained in the mold and freeze in liquid nitrogen for 20min;

[0044] (5) freeze-dry the composite material obtained in step (4) in a freeze-drying machine, the freeze-drying temperature is -30°C, the vacuum is 10Pa, and the freeze-drying time is 20h to form a graphene oxide roll-carbon nanotube composite gas gel;

[0045] (6) Carry out high-temperature carbonization of the airgel obtained in step (5) in a nitrogen atmosphere, the carbonization tempera...

Embodiment 3

[0047] (1) Disperse graphite oxide in deionized water, and obtain 4mg mL by ultrasonic -1 Stable dispersed graphene oxide dispersion;

[0048] (2) Disperse the acidified carbon nanotubes in deionized water, and obtain 1mg mL by ultrasonic -1 Stable dispersed graphene oxide dispersion;

[0049] (3) 10mL 4mg mL -1 Graphene oxide dispersion and 10mL 1mg mL -1 The acidified carbon nanotube dispersion is mixed, and ultrasonicated for a period of time to form a uniform dispersion;

[0050] (4) Place the mixed solution of step (3) gained in the mold and freeze in liquid nitrogen for 20min;

[0051] (5) freeze-dry the composite material obtained in step (4) in a freeze-drying machine, the freeze-drying temperature is -30°C, the vacuum is 10Pa, and the freeze-drying time is 20h to form a graphene oxide roll-carbon nanotube composite gas gel;

[0052] (6) Carry out high-temperature carbonization of the airgel obtained in step (5) in a nitrogen atmosphere, the carbonization tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com