Graphene/ferroferric oxide composite material and preparation method and application thereof

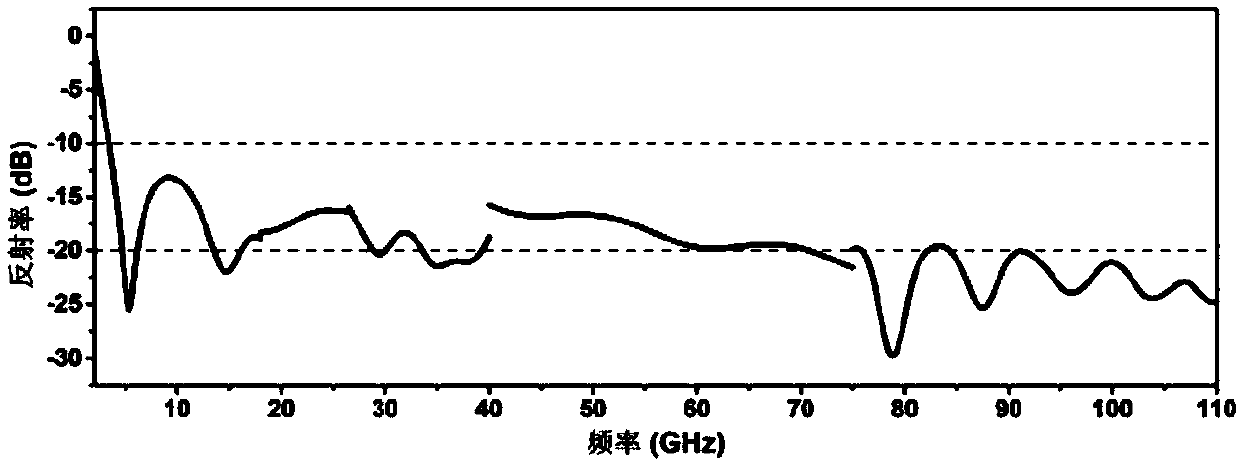

A technology of ferroferric oxide and composite materials, applied in the field of materials, can solve problems such as poor terahertz absorption performance, poor dispersion uniformity, and high absorber density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

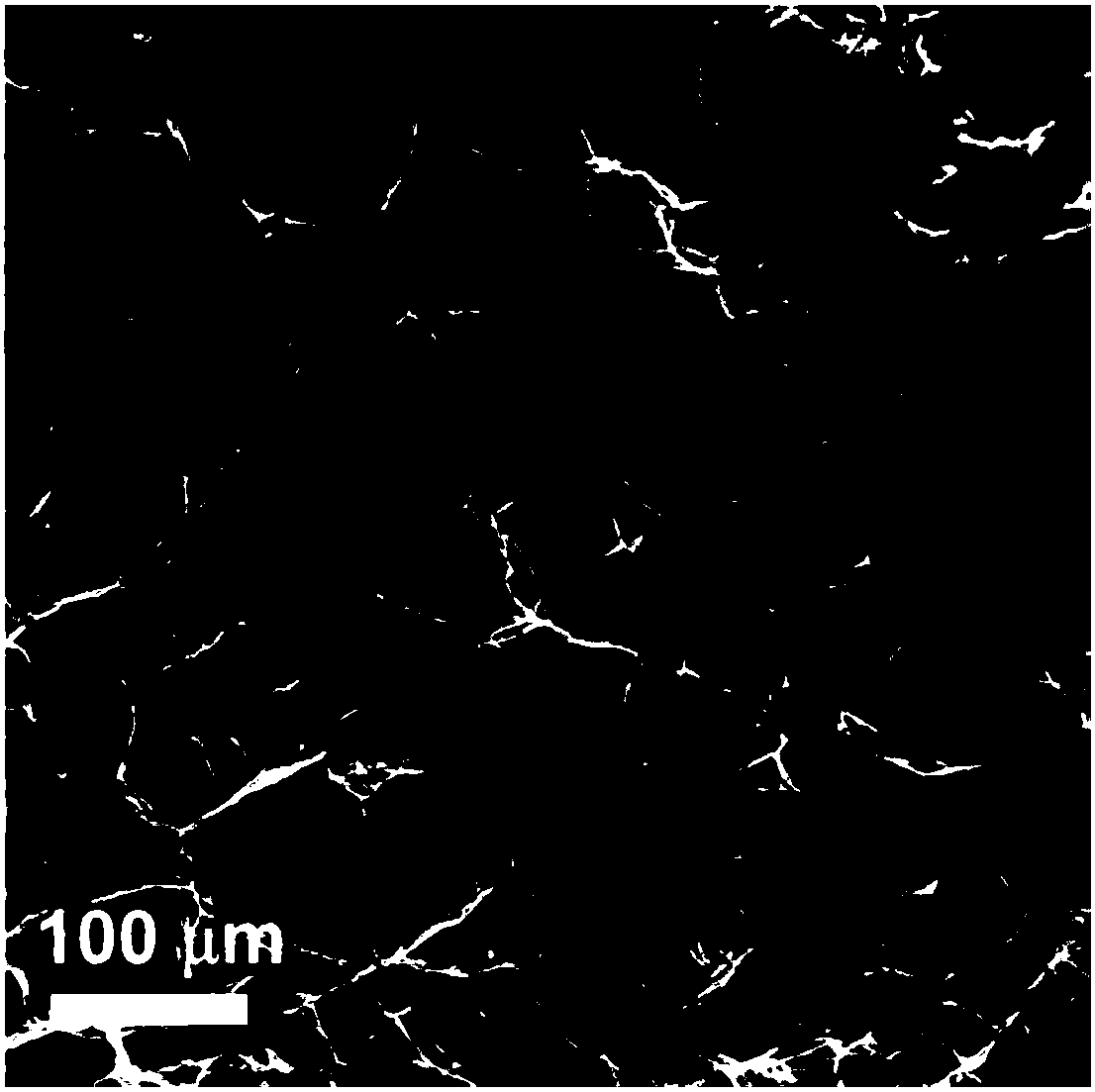

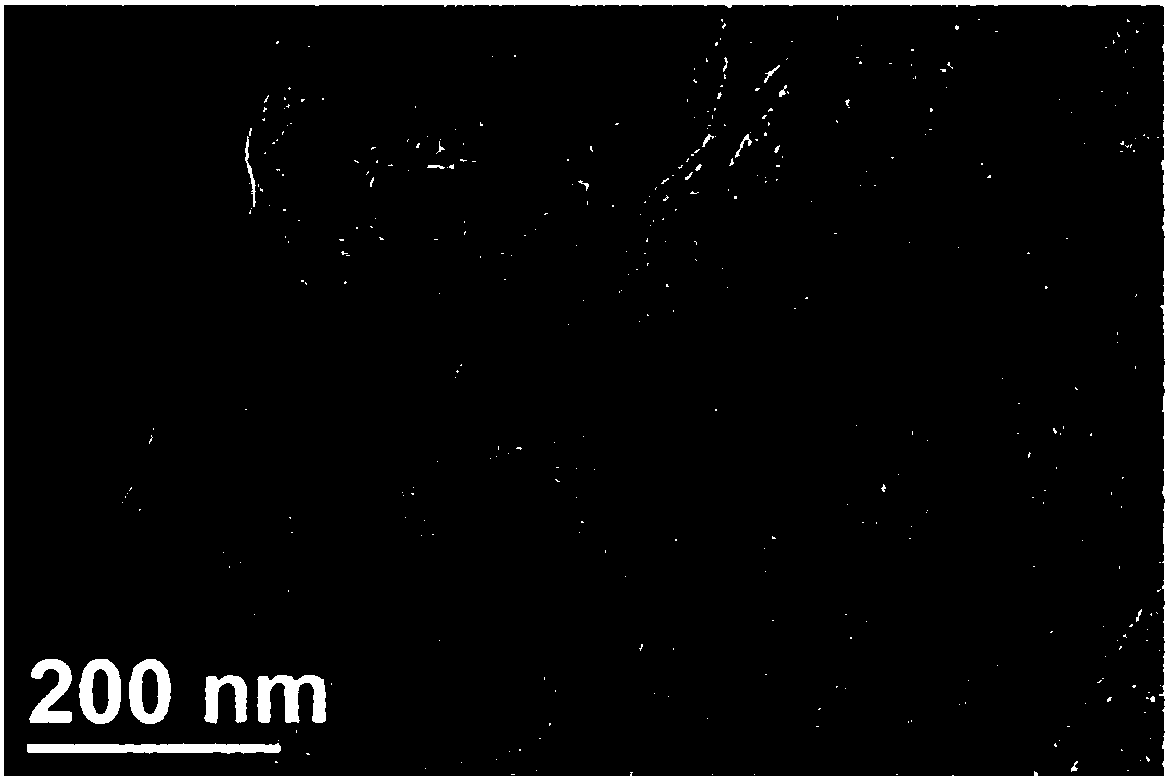

[0139] 1) Weigh graphene oxide and iron triacetylacetonate powder in a container filled with ethanol according to the mass ratio of 1:1, and vigorously sonicate and stir to form a stable colloidal solution. Keep the concentration of graphene oxide in the mixed solution at 1.0mg / ml.

[0140] 2) Transfer the colloidal solution obtained above to a polytetrafluoroethylene lining, put the lining into a stainless steel reactor, and keep it warm at 200°C for 18 hours. After the reactor naturally cools down to room temperature, take out the graphite filled with ethanol ene / iron tetroxide gel-like material, and completely replace it with water system.

[0141] The step of replacing the ethanol in the graphene / ferric oxide gel-like material full of ethanol with water is: the gel-like material is successively placed in a series of mixed solutions of ethanol and water and finally placed in pure In water, wherein the ratio of water in the series of mixed solutions increases successively a...

Embodiment 2

[0149] 1) Weigh graphene oxide and iron triacetylacetonate powder in a container filled with ethanol according to the mass ratio of 1.5:1, and vigorously sonicate and stir to form a stable colloidal solution. Keep the concentration of graphene oxide in the mixed solution at 2.0mg / ml.

[0150] 2) Transfer the colloidal solution obtained above to a polytetrafluoroethylene lining, put the lining into a stainless steel reactor, keep it warm at 180°C for 12 hours, and take out the ethanol-filled graphite after the reactor naturally cools down to room temperature ene / iron tetroxide gel-like material, and completely replace it with water system.

[0151] 3) The above water system was gradually frozen to a solid state at -70°C.

[0152] 4) Freeze-dry the obtained solid composite of graphene / ferric oxide and ice at -20° C. for 120 h. Then the graphene / ferric oxide composite material is obtained.

[0153] 5) In an inert gas of argon, heat-treat the obtained above-mentioned graphene / i...

Embodiment 3

[0156] 1) Weigh graphene oxide and iron triacetylacetonate powder in a container filled with ethanol according to the mass ratio of 2:1, and vigorously sonicate and stir to form a stable colloidal solution. Keep the concentration of graphene oxide in the mixed solution at 0.75mg / ml.

[0157] 2) Transfer the colloidal solution obtained above to a polytetrafluoroethylene lining, put the lining into a stainless steel reactor, and keep it warm at 160°C for 16 hours. After the reactor naturally cools down to room temperature, take out the graphite filled with ethanol ene / iron tetroxide gel-like material, and completely replace it with water system.

[0158] 3) The above water system was gradually frozen to a solid state at -30°C.

[0159] 4) Freeze-dry the obtained solid composite of graphene / ferric oxide and ice at 5° C. for 150 h. Then the graphene / ferric oxide composite material is obtained.

[0160] 5) In an inert gas of argon, heat-treat the obtained above-mentioned graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com