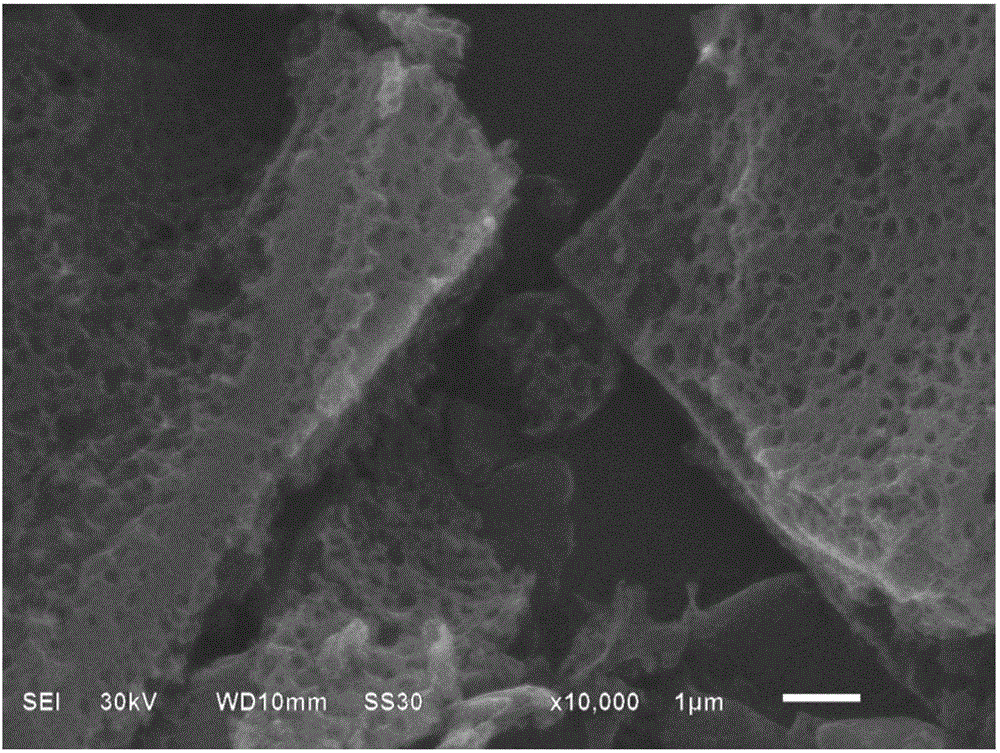

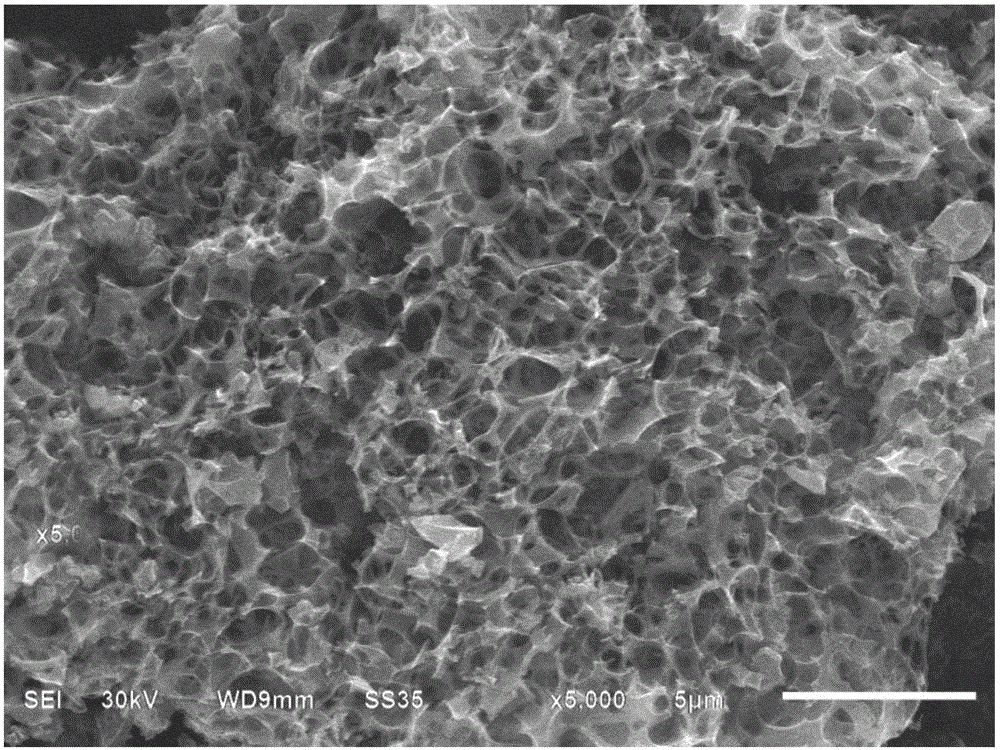

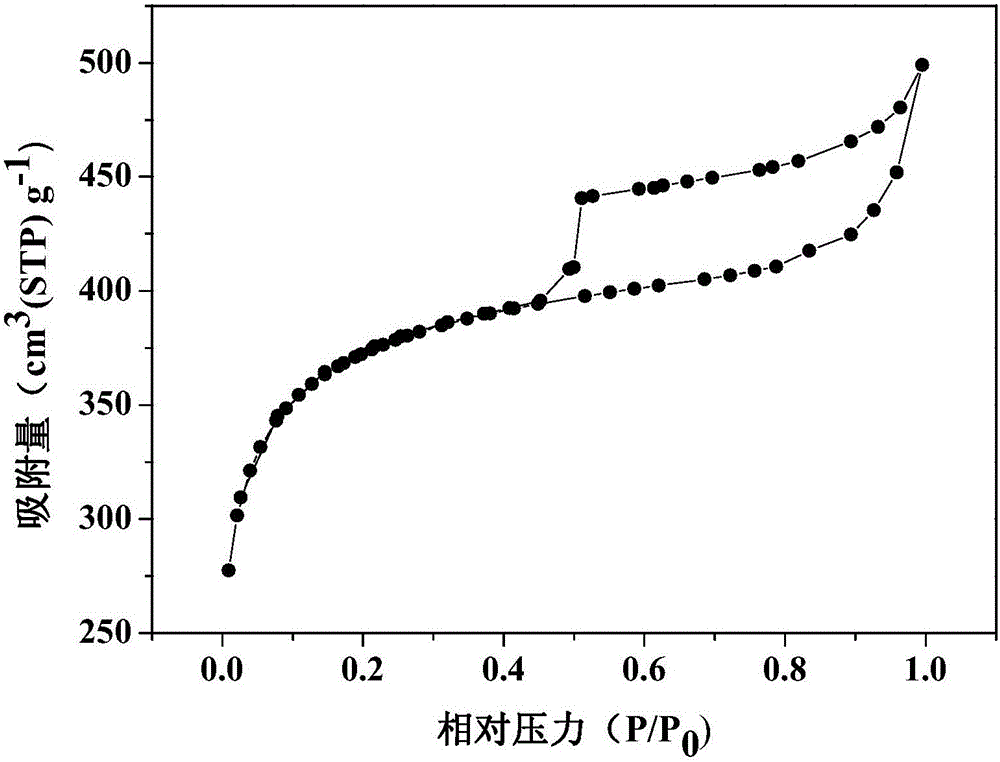

Preparation method and application of porous active carbon material with radix puerariae-based interconnected hierarchical aperture structure

A technology based on porous activated carbon and kudzu root, which is applied in the direction of hybrid capacitor electrodes, etc., can solve the problems such as reports of no relevant literature and patents on activated carbon materials, and achieve the effects of easy industrial production, environmental friendliness, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Wash the kudzu root with water, cut it into discs with a thickness of 5mm, and dry it in a constant temperature drying oven at 100°C for 24 hours to obtain the kudzu root slices on a dry basis. Collect the undersieve to obtain kudzu root powder.

[0041] (2) Add distilled water to the kudzu root powder obtained in step (1) and stir for 0.5h to form a mixture with a liquid / solid ratio of 4, and transfer this mixture to a high-pressure hydrothermal reactor whose inner liner is polytetrafluoroethylene , with a volume filling rate of 0.4, after hydrothermal treatment at 180°C for 12 hours, cool to room temperature, wash the hydrothermal product to neutrality, and then dry it to constant weight at 100°C to obtain kudzu root hydrothermal char.

[0042] (3) Put the kudzu root base hydrothermal carbon coke gained in step (2) in a high-temperature furnace, under N 2 Under the atmosphere, the temperature was raised to 500°C at a heating rate of 5°C / min for 2 hours to obtain ...

Embodiment 2

[0047] (1) Wash Pueraria root with clear water, cut into discs with a thickness of 1mm, and dry in a constant temperature drying oven at 100°C for 24 hours to obtain dry base Puerariae slices, then pulverize dry base Puerariae slices, pass through a 50-mesh sieve, Collect the undersieve to obtain kudzu root powder.

[0048] (2) Add distilled water to the kudzu root powder obtained in step (1) and stir for 0.5h to form a mixture with a liquid / solid ratio of 5, and transfer this mixture to a high-pressure hydrothermal reactor whose inner liner is polytetrafluoroethylene , with a volume filling rate of 0.6, after hydrothermal treatment at 180°C for 18 hours, cool to room temperature, wash the hydrothermal product to neutrality, and then dry it to constant weight at 100°C to obtain kudzu root hydrothermal char.

[0049] (3) Sodium carbonate is made into a solution with a concentration of 3 mol / L, and then the mass ratio of the kudzu root hydrothermal charcoal and sodium carbonate ...

Embodiment 3

[0056] (1) Wash Pueraria root with clean water, cut into discs with a thickness of 2mm, and dry in a constant temperature drying oven at 100°C for 24 hours to obtain dry basis Puerariae slices, then pulverize dry base Pueraria slices, pass through 100-mesh sieve, Collect the undersieve to obtain kudzu root powder.

[0057] (2) add distilled water and stir 1h in the kudzu root powder that step (1) obtains, be made into the mixture that liquid / solid ratio is 5, and this mixture is transferred to the high-pressure hydrothermal reactor that liner is polytetrafluoroethylene, The volume filling ratio was 0.6, after hydrothermal treatment at 180°C for 12 hours, it was cooled to room temperature, the hydrothermal product was washed to neutrality, and then dried to constant weight at 100°C to obtain kudzu root hydrothermal char.

[0058] (3) Zinc chloride is made into a solution with a concentration of 2mol / L, and then the kudzu root hydrothermal charcoal prepared in step (2) is added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com