Method for preparing meso-porous material from natural mordenite

A technology of mordenite and mesoporous materials, applied in chemical instruments and methods, crystalline aluminosilicate zeolite, aluminum silicate, etc., can solve the problems of limited primary processing, high performance, high added value and less, and achieve low cost , The production process and its equipment are simple, and the effect of acid and alkali resistance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

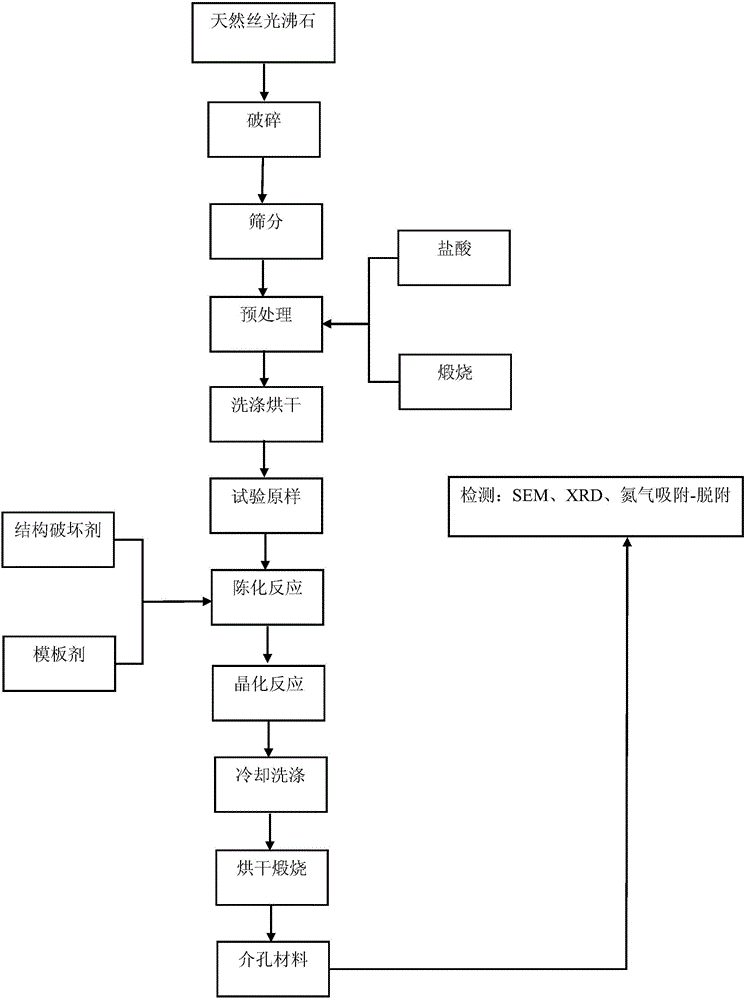

[0044] The method for preparing mesoporous material by utilizing natural mordenite comprises the following steps:

[0045] Step 1, raw material pretreatment:

[0046] (1) Crushing and screening the natural mordenite, taking the natural mordenite granules with a particle size of less than or equal to 200 meshes;

[0047] (2) calcining the natural mordenite at 850° C. for 3 hours;

[0048](3) Soak the calcined natural mordenite particles in 5% HCl for 24 hours, filter, wash until neutral, and dry to obtain natural mordenite particles with internal pores removed;

[0049] Step 2, Aging:

[0050] (1) by the quality of the natural mordenite particle of clearing internal channel: the quality of ammonium fluoride: the quality of sodium hydroxide: the quality=10:10:1.6:10 of tri-n-butylamine, get the natural mordenite of clearing internal channel Granules, ammonium fluoride solution, sodium hydroxide solution and tri-n-butylamine solution, stirred evenly to obtain a mixture;

[00...

Embodiment 2

[0063] The method for preparing mesoporous material by utilizing natural mordenite comprises the following steps:

[0064] Step 1, raw material pretreatment:

[0065] (1) Crushing and screening the natural mordenite, taking the natural mordenite granules with a particle size of less than or equal to 200 meshes;

[0066] (2) calcining natural mordenite at 800°C for 3h;

[0067] (3) Soak the calcined natural mordenite particles in 6% HCl for 24 hours, filter, wash until neutral, and dry to obtain natural mordenite particles with internal pores removed;

[0068] Step 2, Aging:

[0069] (1) by the quality of the natural mordenite particle of clearing internal channel: the quality of ammonium fluoride: the quality of sodium hydroxide: the quality=10:11:2.4:13 of tri-n-butylamine, get the natural mordenite of clearing internal channel Granules, ammonium fluoride solution, sodium hydroxide solution and tri-n-butylamine solution, stirred evenly to obtain a mixture;

[0070] Wherei...

Embodiment 3

[0080] The method for preparing mesoporous material by utilizing natural mordenite comprises the following steps:

[0081] Step 1, raw material pretreatment:

[0082] (1) Crushing and screening the natural mordenite, taking the natural mordenite granules with a particle size of less than or equal to 200 meshes;

[0083] (2) calcining the natural mordenite at 850° C. for 2 hours;

[0084] (3) Soak the calcined natural mordenite particles in 7% HCl for 20 hours, filter, wash until neutral, and dry to obtain natural mordenite particles with internal pores removed;

[0085] Step 2, Aging:

[0086] (1) by the quality of the natural mordenite particle of clearing internal channel: the quality of ammonium fluoride: the quality of sodium hydroxide: the quality=10:8:3.2:11 of tri-n-butylamine, get the natural mordenite of clearing internal channel Granules, ammonium fluoride solution, sodium hydroxide solution and tri-n-butylamine solution, stirred evenly to obtain a mixture;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com