Method for removing manganese ions in water by using N-S element synergetic modified graphene electrode

A graphene electrode, manganese ion technology, applied in separation methods, chemical instruments and methods, water/sewage treatment and other directions, can solve problems such as the decline in the utilization quality of industrial water and domestic drinking water, and achieve a simple and easy preparation method. Short, high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

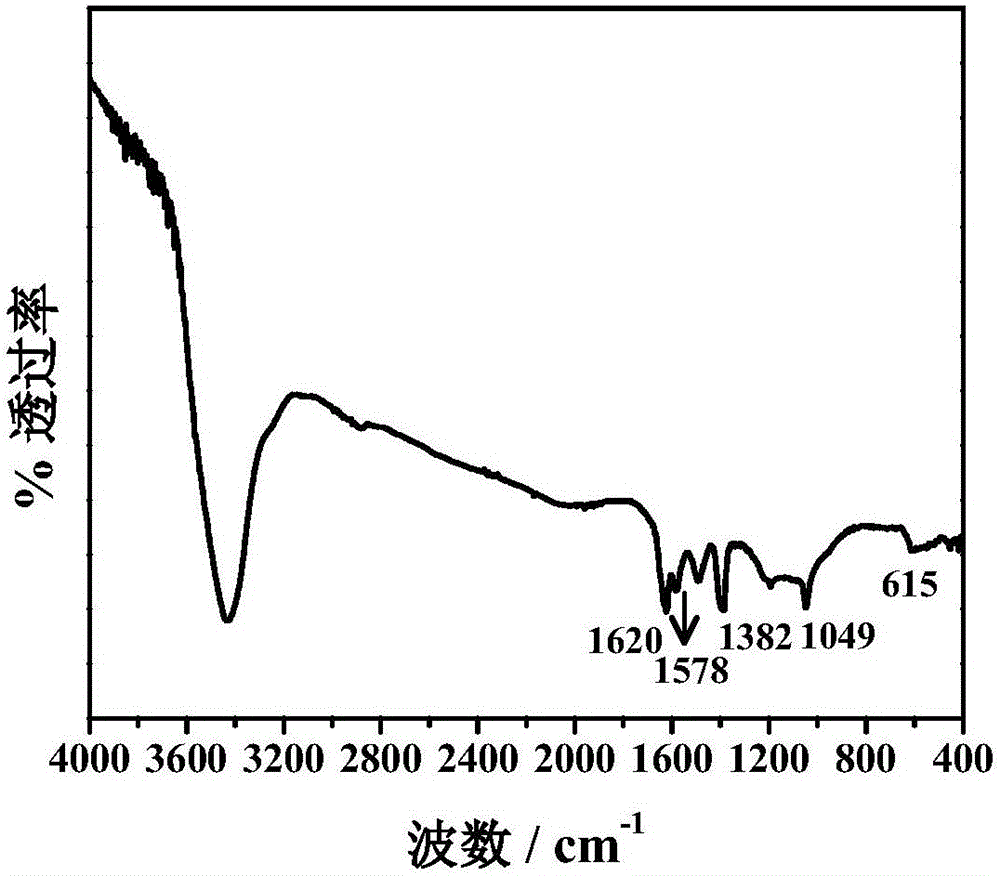

[0020] The preparation of nitrogen-sulfur co-doped graphene airgel paper electrode includes the following steps:

[0021] (1) Ultrasonic disperse 0.15g of graphene oxide (GO) in 100mL of distilled water, then add 0.45g of L-cysteine, stir it mechanically to make it fully mixed, and then put the mixture at 95°C Heated in a water bath for 2h. After the reaction, the resulting product was immersed in distilled water for 2-3 days, and finally the sample was freeze-dried at -52°C for 24 hours to obtain nitrogen-sulfur co-doped graphene airgel.

[0022] (2) Add 90mg of the nitrogen-sulfur co-doped graphene airgel material prepared in step (1) into 2mL of 4wt% polyvinyl alcohol solution, and ultrasonically disperse the composite material in the solution evenly. Take 0.16mL of the above dispersion liquid and apply it evenly on a 35mm×8mm hard paper sheet (thickness 400μm), and freeze-dry it at -52°C for 12h to make a nitrogen-sulfur co-doped graphene airgel paper electrode.

Embodiment 2

[0024] The preparation process of the nitrogen-sulfur co-doped graphene airgel paper electrode is the same as that of Example 1.

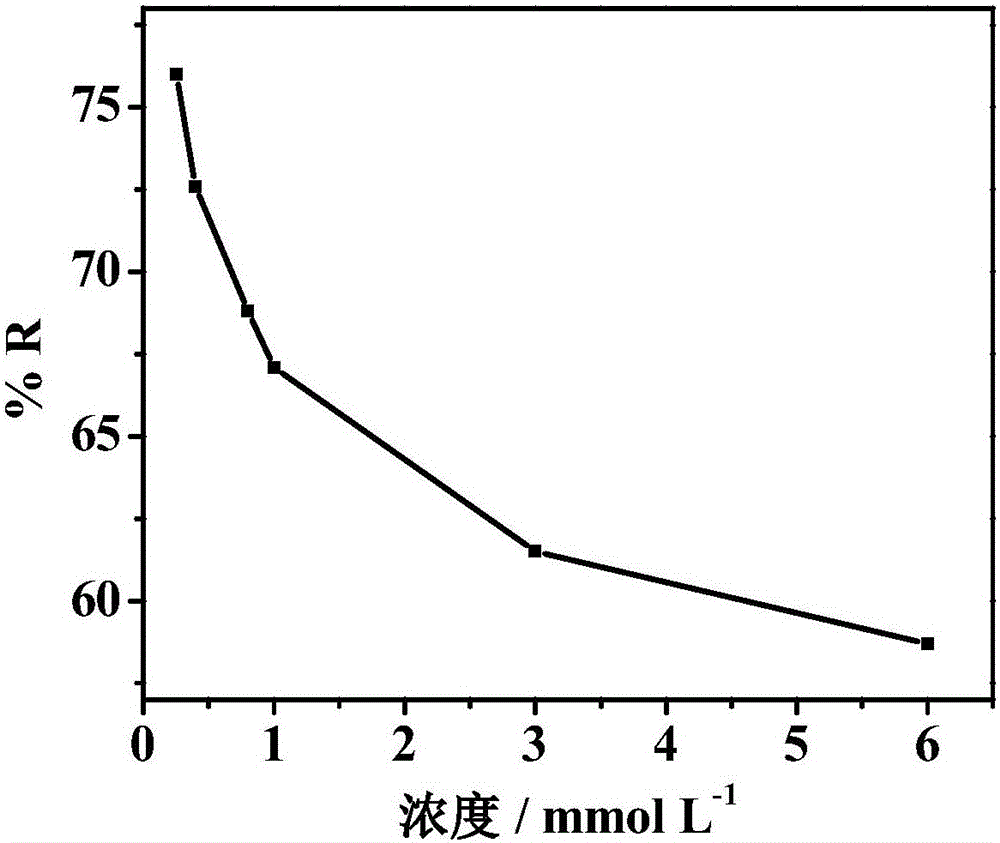

[0025] The prepared nitrogen-doped graphene airgel paper electrodes were used for 0.25, 0.4, 0.8, 1, 3 and 6 mM Mn 2+ Electrochemical treatment of the solution, the applied voltage is 0.3V, the treatment time is 2min, Mn 2+ The removal rate see figure 2 , it can be seen that the nitrogen-doped graphene airgel material has a low concentration of Mn 2+ The solution has a better adsorption effect.

Embodiment 3

[0027] The preparation process of the nitrogen-sulfur co-doped graphene airgel paper electrode is the same as that of Example 1.

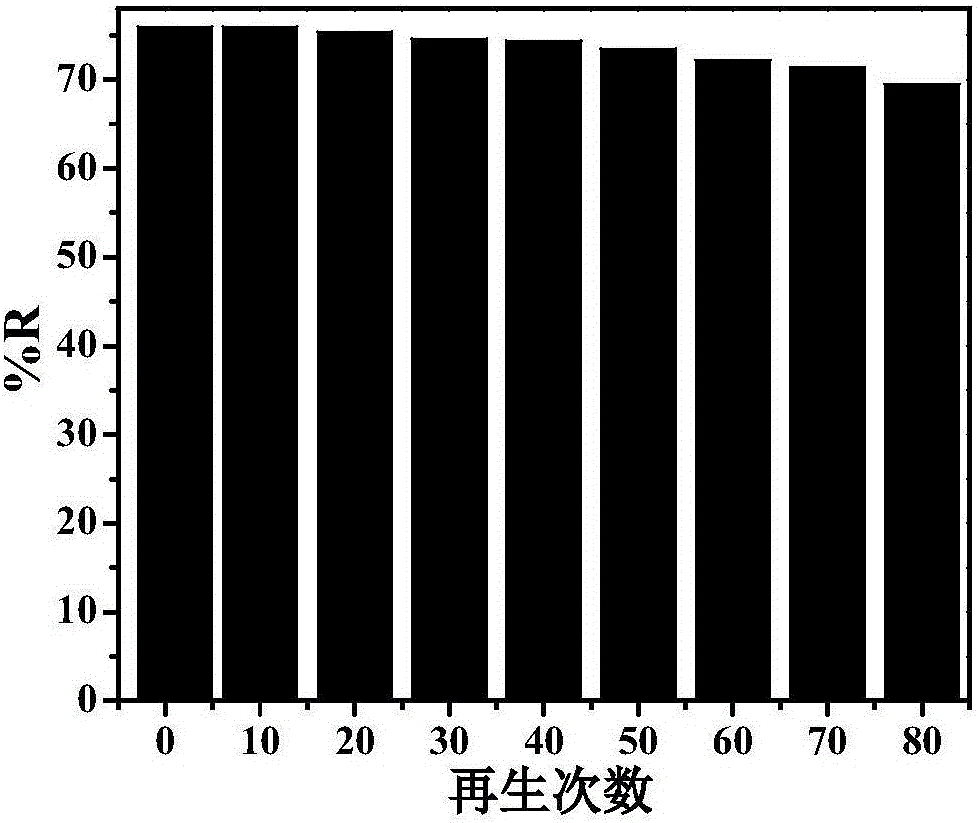

[0028] Cyclic electrosorption experiments on nitrogen-sulfur co-doped graphene airgel paper electrodes. The nitrogen-sulfur co-doped graphene airgel paper electrode was placed in 80 mL of Mn with a concentration of 0.25 mmol / L 2+ In the solution, apply a potential of -0.3V, and record the conductivity of the solution, record the conductivity of the solution again after 2 minutes, and calculate the removal rate. Then the potential was removed to allow it to desorb, and the cycle was repeated several times. Experimental results such as image 3 shown. The first adsorption of Mn 2+ The removal rate was 76%. After 30 cycles of use, the electrode paired with Mn 2+ The removal rate was 74.7%, and then the electro-adsorption cycle experiment was continued, the electro-adsorption removal rate gradually decreased, and the removal rate was 69.5% after 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com