Integral membrane coagulation reactor (MCR) and water treatment technology

A membrane coagulation, integrated technology, applied in the fields of flocculation/sedimentation water/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc. The problems of easy precipitation of pores and particles can achieve the effect of reducing floor space, low operating cost, and convenient operation and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment is raw water treatment, and the content of dissolved organic carbon (DOC) in the water to be treated is 2-10 mg / L. Conventional coagulation membrane treatment process (conventional equipment including independent coagulation unit, precipitation unit and membrane treatment unit) is adopted. Continue to add aluminum salt coagulant, calculated as aluminum, 5mg / L per day. Among them, the mechanical stirring is fast rotation (200rpm) 1min, slow rotation (50rpm) 15min. Pump the raw water into the coagulation tank, and after passing through the sedimentation tank, use 1m 3 / h enters the membrane pool, and the hydraulic retention time in the membrane pool is 0.5h. The sludge is discharged through the sedimentation tank, and the frequency of sludge discharge is 3 days / time. After 30 days of continuous operation, the transmembrane pressure difference increased to 48kPa, and the removal rate of DOC in the effluent was 79%.

Embodiment 2

[0034] This embodiment is raw water treatment, and the content of dissolved organic carbon (DOC) in the water to be treated is 2-10 mg / L. Short-flow process (conventional equipment including independent coagulation unit and membrane treatment unit) is adopted. Continue to add aluminum salt coagulant, calculated as aluminum, 5mg / L per day. Among them, the mechanical stirring is fast rotation (200rpm) 1min, slow rotation (50rpm) 15min. Pump the raw water into the coagulation tank, and with 1m 3 / h enters the membrane pool, and the hydraulic retention time in the membrane pool is 0.5h. Continuous operation for 30 days, mud discharge frequency is 3 days / time. Stand still for 30 minutes each time the sludge is discharged, and open the sludge discharge valve at the bottom of the membrane tank to discharge half of the sediment. After 30 days of continuous operation, the transmembrane pressure difference increased to 42kPa, and the removal rate of DOC in the effluent was 81%.

Embodiment 3

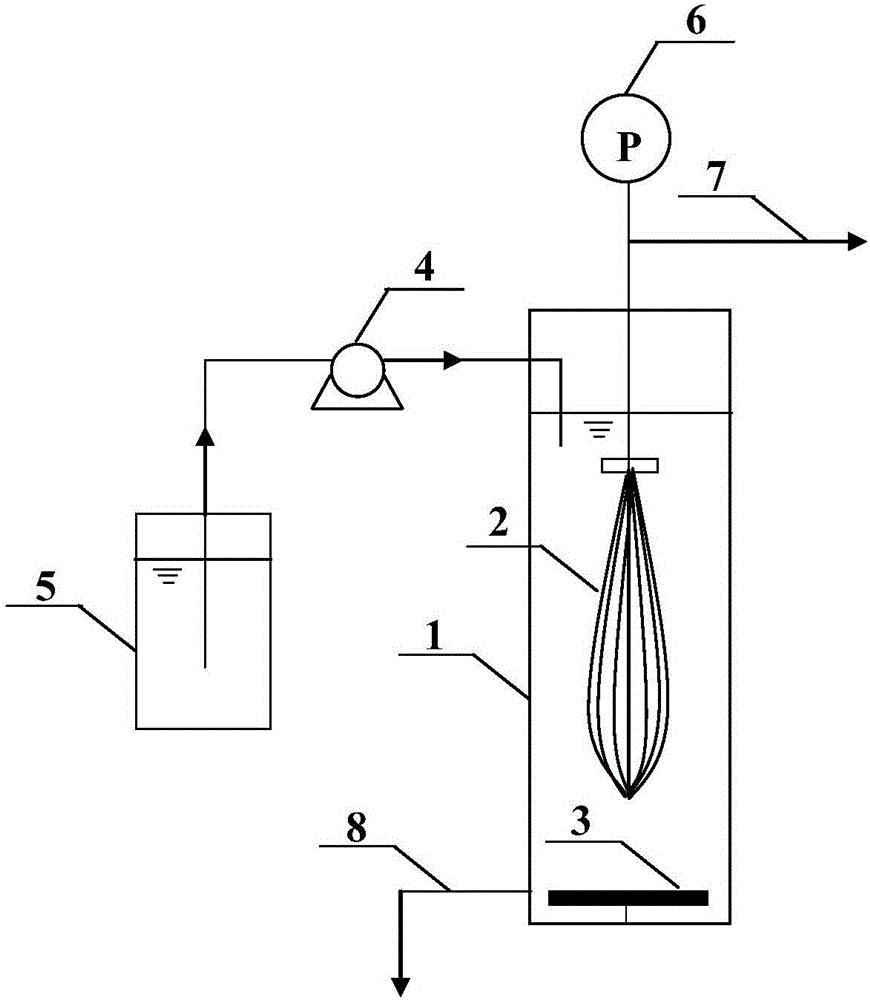

[0036] refer to figure 1 As shown, in an exemplary embodiment of the present invention, an integrated membrane coagulation reactor includes: a membrane tank 1, a membrane module 2 and an aeration device 3 arranged in the same membrane tank; the membrane tank 1 passes through the tube The series series suction pump 4 is connected with the coagulant dosing pool 5. The membrane module 2 is also connected with the vacuum pressure gauge 6 through pipelines. The reactor is also provided with a water outlet 7 of the membrane pool. A sludge discharge valve 8 is also provided at the bottom of the membrane pool 1 .

[0037] This embodiment is raw water treatment, and the content of dissolved organic carbon (DOC) in the water to be treated is 2-10 mg / L. Using the integrated membrane coagulation reactor and water treatment process of the present invention, such as figure 1 As shown, the coagulant dosing tank 5 contains aluminum salt coagulant, and the membrane module 2 and the aeratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com