Comprehensive treatment method for livestock and poultry breeding wastewater

A technology for comprehensive treatment of livestock and poultry breeding wastewater, applied in the field of livestock and poultry wastewater treatment, can solve the problems of inability to meet wastewater treatment requirements, large area for forest restoration treatment, single biogas utilization method, etc., and achieves high energy recovery and utilization rate. The effect of improving energy recovery rate and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

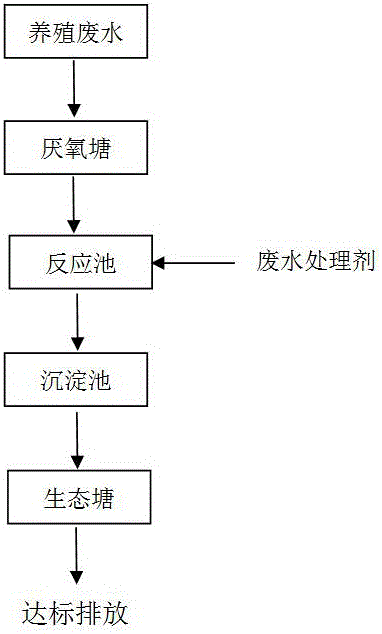

[0040] For the waste water discharge from the livestock and poultry breeding plant A, the comprehensive treatment method for livestock and poultry breeding wastewater of the present invention is adopted, and the specific steps are as follows:

[0041] (1) After the conventional solid-liquid separation pretreatment, the aquaculture wastewater flows into the anaerobic pond for anaerobic reaction, and the reaction time is 7d;

[0042] (2) The effluent from the anaerobic pond enters the reaction tank, and after adding the wastewater treatment agent to the reaction tank for reaction 6, it enters the sedimentation tank for sedimentation for 2 hours;

[0043] (3) The effluent from the sedimentation tank will be discharged up to the standard after being intensified by the ecological pond.

[0044]The raw materials of the waste water treatment agent in step (2), in parts by weight, include: 45 parts of blast furnace slag, 22 parts of sodium carbonate, 10 parts of polydimethyldiallyl am...

Embodiment 2

[0053] The waste water from the livestock and poultry breeding plant B is discharged, and the comprehensive treatment method of the livestock and poultry breeding wastewater of the present invention is adopted, and the specific steps are as follows:

[0054] (1) After the conventional solid-liquid separation pretreatment, the aquaculture wastewater flows into the anaerobic pond for anaerobic reaction, and the reaction time is 10d;

[0055] (2) The effluent from the anaerobic pond enters the reaction tank, and after adding the wastewater treatment agent to the reaction tank for 12 hours, it enters the sedimentation tank for sedimentation for 4 hours;

[0056] (3) The effluent from the sedimentation tank will be discharged up to the standard after being intensified by the ecological pond.

[0057] The raw materials of the waste water treatment agent in step (2) include: 55 parts by weight of blast furnace slag, 25 parts of sodium carbonate, 15 parts of polydimethyldiallyl ammoni...

Embodiment 3

[0066] For the waste water discharge from the livestock and poultry breeding plant C, the comprehensive treatment method for livestock and poultry breeding wastewater of the present invention is adopted, and the specific steps are as follows:

[0067] (1) After the conventional solid-liquid separation pretreatment, the aquaculture wastewater flows into the anaerobic pond for anaerobic reaction, and the reaction time is 8d;

[0068] (2) The effluent from the anaerobic pond enters the reaction tank, and after adding the wastewater treatment agent to the reaction tank for 9 hours, it enters the sedimentation tank for sedimentation for 3 hours;

[0069] (3) The effluent from the sedimentation tank will be discharged up to the standard after being intensified by the ecological pond.

[0070] The raw materials of the waste water treatment agent in step (2) include: 50 parts by weight of blast furnace slag, 23 parts of sodium carbonate, 12 parts of polydimethyldiallyl ammonium chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com