Near-infrared luminescence transparent glass ceramic and preparation method thereof

A transparent glass and near-infrared technology, applied in the field of solid luminescent materials, can solve the problems of near-infrared luminescence of quenching materials, poor chemical stability and mechanical properties of bulk materials, etc., and achieve excellent mechanical strength and physical and chemical properties, and long fluorescence lifetime , the effect of high fluorescence emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] (1) Weigh 56.95mmol SiO 2 , 12mmol Al 2 o 3 , 10mmol CaO, 18mmol Na 2 O, 3mmol In 2 o 3 and 0.05mmol Er 2 o 3 Powder, ground for half an hour and mixed evenly, placed in a crucible, heated to 1520 degrees in a high-temperature furnace and kept for 0.5 hours to obtain a glass solution;

[0018] (2) Quickly pour the glass melt into a copper mold preheated at 300°C to form a precursor glass;

[0019] (3) After the precursor glass was annealed at 500°C and then kept at 660°C for 2 hours, a transparent glass-ceramic doped with 0.1 mol% erbium ions was obtained.

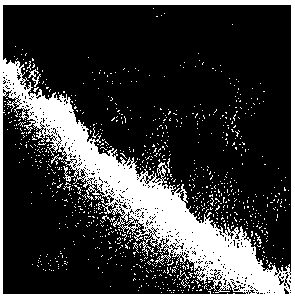

[0020] Microscopic analysis by high-resolution transmission electron microscopy showed that (such as figure 1 Shown): In the glass ceramics, a large number of indium oxide quantum dots with a size of 3-4 nm are evenly distributed on the oxide glass matrix.

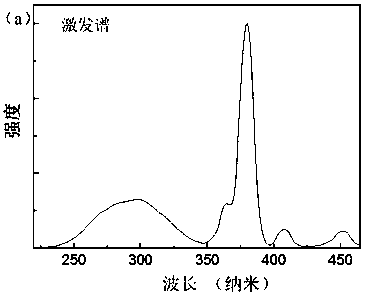

[0021] Depend on figure 2 The excitation spectrum in the figure shows that after the surface of the transparent glass-ceramic sample is polished, an ...

example 2

[0023] (1) Weigh 53mmol SiO 2 , 14mmol Al 2 o 3 , 10mmol CaO, 16mmol Na 2 O, 5mmol In 2 o 3 and 2 mmol Er 2 o 3 , after grinding for half an hour and mixing evenly, put it in a crucible, heat it in a high-temperature furnace to 1480°C for 1 hour, and obtain a glass solution;

[0024] (2) Quickly pour the glass melt into a copper mold preheated at 300°C to form a precursor glass;

[0025] (3) After the precursor glass was annealed at 500°C, and then kept at 720°C for 8h, a transparent glass-ceramic doped with 4 mol% erbium ions was obtained.

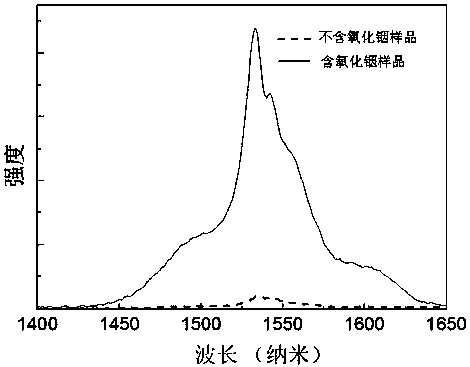

[0026] After the surface of the sample is polished, a wide ultraviolet excitation band is measured at 320 nm; under the light excitation of 320 nm, the near-infrared fluorescence emission of erbium ions with a peak at 1534 nm is obtained, and the intensity of the fluorescence emission peak is the same as that without indium oxide quantum 8 times the spot sample; and measured 4 I 13 / 2 The fluorescence decay lifetime of the energy...

example 3

[0028] (1) Weigh 64.99 mmol SiO 2 , 10 mmol Al 2 o 3 , 7 mmol CaO, 17 mmol Na 2 O, 1 mmol In 2 o 3 and 0.01 mmol Er 2 o 3 , After grinding for half an hour and mixing evenly, place it in a crucible, heat it in a high-temperature furnace to 1650°C for 4 hours, and obtain a glass solution;

[0029] (2) Quickly pour the glass melt into a copper mold preheated at 300°C to form a precursor glass;

[0030] (3) After annealing the precursor glass at 480°C, and then holding it at 850°C for 0.5h, a transparent glass-ceramic doped with 0.2 mol% erbium ions was obtained.

[0031] After the surface of the sample is polished, a wide ultraviolet excitation band is measured at 350nm; under the light excitation of 350nm, the near-infrared fluorescence emission of erbium ions with a peak at 1534 nm is obtained, and the intensity of the fluorescence emission peak is the same as that without indium oxide quantum dots. 6 times the sample, measured 4 I 13 / 2 The fluorescence decay lifeti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com