Inorganic permeable water-retaining cement concrete gelatinizing agent and preparation method thereof

A technology of cement concrete and inorganic type, which is applied in the field of inorganic type water-permeable and water-retaining cement concrete gelling agent and its preparation field to achieve the effects of protecting soil moisture, improving living conditions and preventing cement from sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

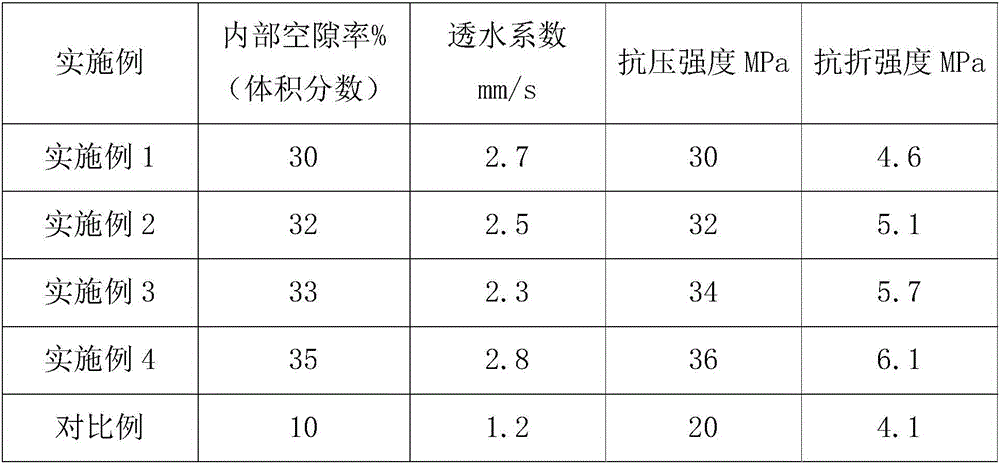

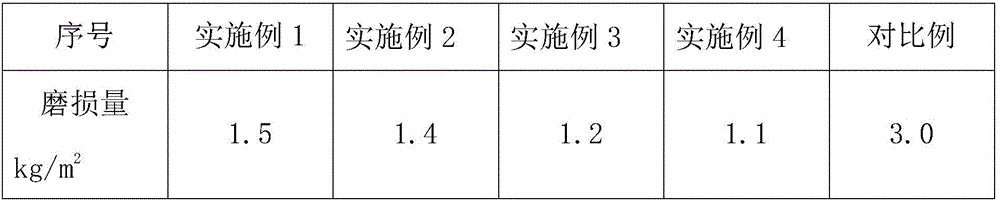

Examples

Embodiment 1

[0049] The inorganic water-permeable and water-retaining cement concrete gelling agent provided by the present invention, based on a one ton reactor, includes the following components:

[0050] 130 kg of ferrous sulfate, 30 kg of iron sulfate, 20 kg of sodium sulfate, 30 kg of magnesium chloride, 20 kg of potassium sulfate, 20 kg of ammonium sulfate, 180 kg of calcium chloride, 0.5 kg of dispersant, 0.5 kg of sodium gluconate, and 569 kg of water .

[0051] The inorganic permeable and water-retaining cement concrete gelling agent includes the following steps:

[0052] The above-mentioned raw materials are sequentially added to water, heated and stirred until completely dissolved to obtain the inorganic permeable and water-retaining cement concrete gelling agent.

Embodiment 2

[0054] The inorganic water-permeable and water-retaining cement concrete gelling agent provided by the present invention, based on a one ton reactor, includes the following components:

[0055] Ferrous sulfate 180 kg, ferrous sulfate 90 kg, sodium sulfate 80 kg, magnesium chloride 90 kg, potassium sulfate 80 kg, ammonium sulfate 40 kg, calcium chloride 200 kg, zeolite powder 0.5 kg, calcium oxide 0.5 kg, sodium gluconate 1.5 Kg, 237 kg of water;

[0056] All the above raw materials are of analytical grade.

[0057] This type of water-permeable and water-retaining cement concrete gelling agent specifically includes the following steps:

[0058] (1) Add a predetermined percentage of ferrous sulfate, ferric sulfate, sodium sulfate, magnesium chloride, potassium sulfate, and ammonium sulfate to 50 kg, 20 kg, 15 kg, 20 kg, 15 kg, and 10 kg water respectively, and stir for 15 minutes to complete Dissolve, obtain ferrous sulfate solution, ferric sulfate solution, sodium sulfate solution, ma...

Embodiment 3

[0063] The inorganic water-permeable and water-retaining cement concrete gelling agent provided by the present invention, based on a one ton reactor, includes the following components:

[0064] 150 kg of ferrous sulfate, 60 kg of iron sulfate, 50 kg of sodium sulfate, 60 kg of magnesium chloride, 50 kg of potassium sulfate, 30 kg of ammonium sulfate, 188 kg of calcium chloride, 0.5 kg of 2000 mesh zeolite powder, 0.5 kg of analytical grade calcium oxide, 1 kg of sodium gluconate and 410 kg of water;

[0065] All the above raw materials are of analytical grade.

[0066] Non-model permeable and water-retaining cement concrete gelling agent, specifically including the following steps:

[0067] (1) Add a predetermined percentage of ferrous sulfate, ferric sulfate, sodium sulfate, magnesium chloride, potassium sulfate, and ammonium sulfate to 100 kg, 40 kg, 30 kg, 40 kg, 30 kg, and 20 kg water respectively, and the dissolution temperature is 45 respectively ℃, 25℃, 55℃, 28℃, 60℃ and 45℃, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com