Process and device for recycling dimethyl carbonate through steam permeation method

A technology of dimethyl carbonate and permeation method, which is applied in the field of recovery of dimethyl carbonate by steam permeation method, can solve the problems of high energy consumption, high investment in equipment, complicated separation process, etc., and achieve small processing load, reduced pressure, membrane small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

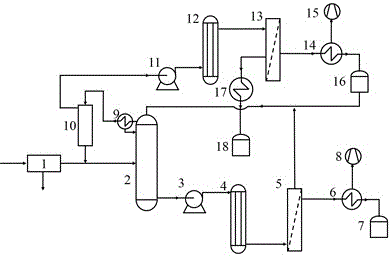

[0047] Add the reaction liquid in the preparation of dimethyl carbonate by transesterification reaction to the initial distillation tower 1, the bottom of the tower is part of by-products, the top of the tower is dimethyl carbonate-methanol azeotrope, and trace impurities, the azeotropic temperature is about 63 °C . After the dimethyl carbonate-methanol azeotrope enters the extractive distillation tower 2 for extraction and separation with water, the bottom of the extractive distillation tower 2 is about 95% of water, 5% of methanol and less than 0.05% of dimethyl carbonate and trace impurities mixture. The control flow rate is 90kg / h. Water-methanol-dimethyl carbonate enters the first evaporator 4, and after being vaporized, enters the first vapor permeation membrane separator 5 composed of 4 MFI molecular sieve membrane modules in series for dealcoholization and separation. The feed temperature in the first steam permeation membrane separator 5 is 120°C, the gauge pressure ...

Embodiment 2

[0049] After the reaction solution in the dimethyl carbonate prepared by transesterification is heated and vaporized, it is added to the extractive distillation tower 2 and water is extracted and separated, and the bottom of the extractive distillation tower 2 is 92% of water, 5% of methanol and less than 3% of Mixture of dimethyl carbonate and trace impurities. The control flow rate is 90kg / h. Water-methanol-dimethyl carbonate enters the first evaporator 4, and after being vaporized, enters the first vapor permeation membrane separator 5 composed of 4 MFI molecular sieve membrane modules in series for dealcoholization and separation. The feed temperature in the first steam permeation membrane separator 5 is 120°C, the gauge pressure on the retentate side of the membrane is 0.23MPa, and the absolute pressure on the permeate side is 10000Pa. Methanol in the feed liquid passes through the steam permeation membrane, is condensed by the first condenser 6 of the permeate, and then ...

Embodiment 3

[0051] Add the reaction solution in the preparation of dimethyl carbonate by methanol carbonylation to the initial distillation tower 1, the bottom of the tower is part of by-products, the top of the tower is dimethyl carbonate-methanol azeotrope, and trace impurities, the azeotropic temperature is 63 ℃ . After the dimethyl carbonate-methanol azeotrope enters the extractive distillation tower 2 and carries out extraction and separation with water, the bottom of the extractive distillation tower 2 is about 94% water, 6% methanol and less than 0.05% dimethyl carbonate ternary sum Mixture of trace impurities. The control flow rate is 180kg / h. Water-methanol-dimethyl carbonate enters the first evaporator 4, and after being vaporized, it enters the first vapor permeation membrane separator 5 composed of 6 MFI molecular sieve membrane modules in series for dealcoholization and separation. The feed temperature in the first steam permeation membrane separator 5 is 120°C, the gauge pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com