Preparation method of polyurethane curing agent intermediate and curing agent

A technology of polyurethane curing agent and intermediate, which is applied in the field of polyurethane materials and can solve problems such as poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

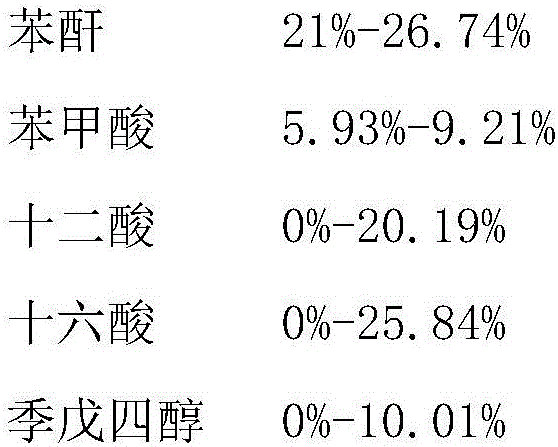

[0024] A kind of intermediate for polyurethane curing agent, its composition component is as follows by mass percentage:

[0025]

[0026] The preparation method of the intermediate for the polyurethane curing agent of this embodiment:

[0027] Step 1, venting nitrogen, first putting the liquid material glycerin, hypophosphorous acid and refluxed xylene into the reaction kettle successively, and then dropping into the solid material dodecanoic acid, benzoic acid, phthalic anhydride, pentaerythritol;

[0028] Step 2, start to heat up slowly, and turn on the reflux cooling water, when most of the materials melt, start stirring, continue to heat up after the stirring starts, and stop nitrogen after the reflux is stable;

[0029] Step 3: Slowly increase the reaction temperature to 190°C, and at a reaction temperature of 190°C to 215°C, reflux esterification for 2 hours and then take a sample to titrate the solid acid value. When the solid acid value is 2.0-3.0mgKOH / g, blow nitr...

Embodiment 2

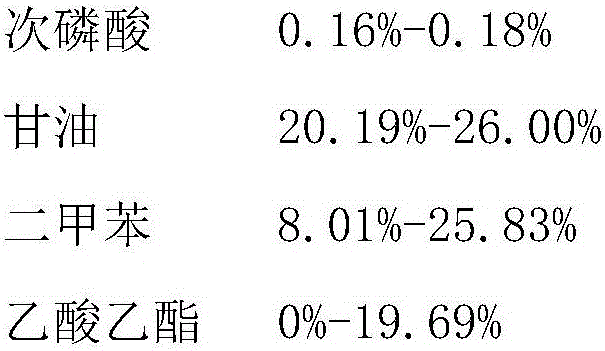

[0031] A kind of intermediate for polyurethane curing agent, its composition component is as follows by mass percentage:

[0032]

[0033] The preparation method is the same as in Example 1.

Embodiment 3

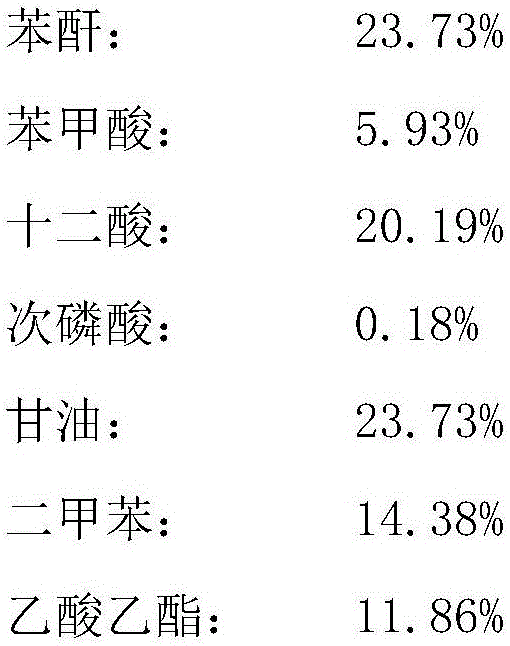

[0035] A kind of intermediate for polyurethane curing agent, its composition component is as follows by mass percentage:

[0036]

[0037] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com