Composite catalyst for preparing polyether-polylactide-aliphatic polycarbonate ternary block copolymer and application of composite catalyst

A technology of composite catalyst and polylactide, which is applied in the polymer field to achieve good catalytic effect, narrow molecular weight distribution and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]

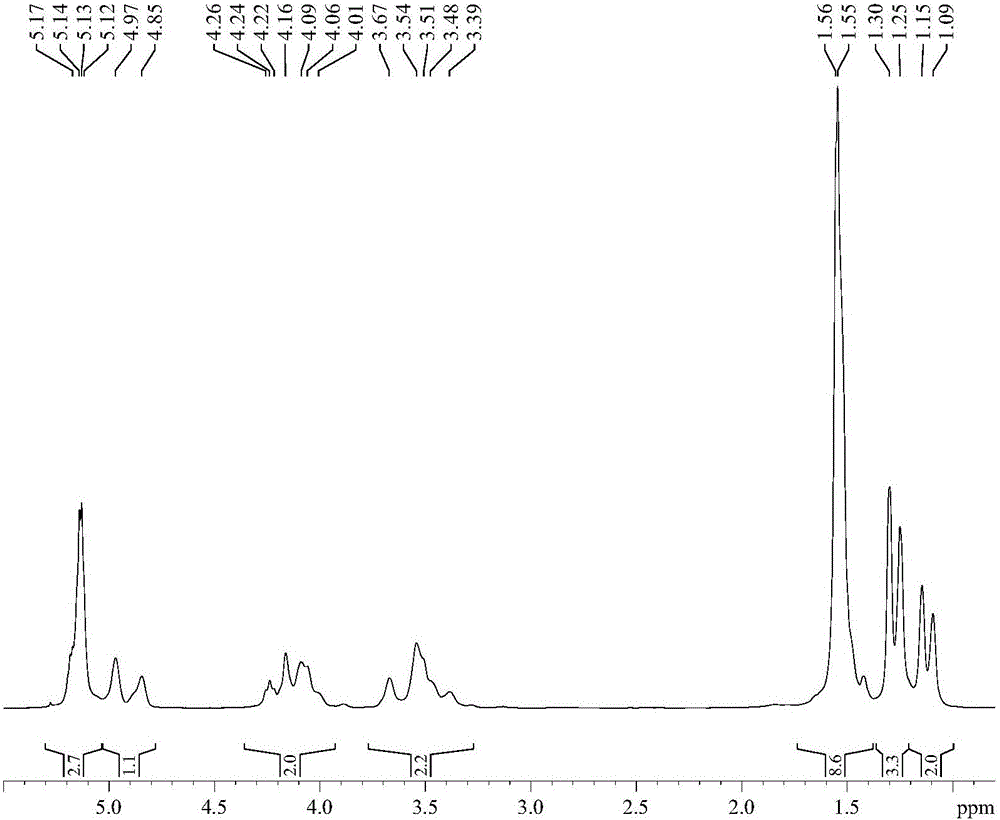

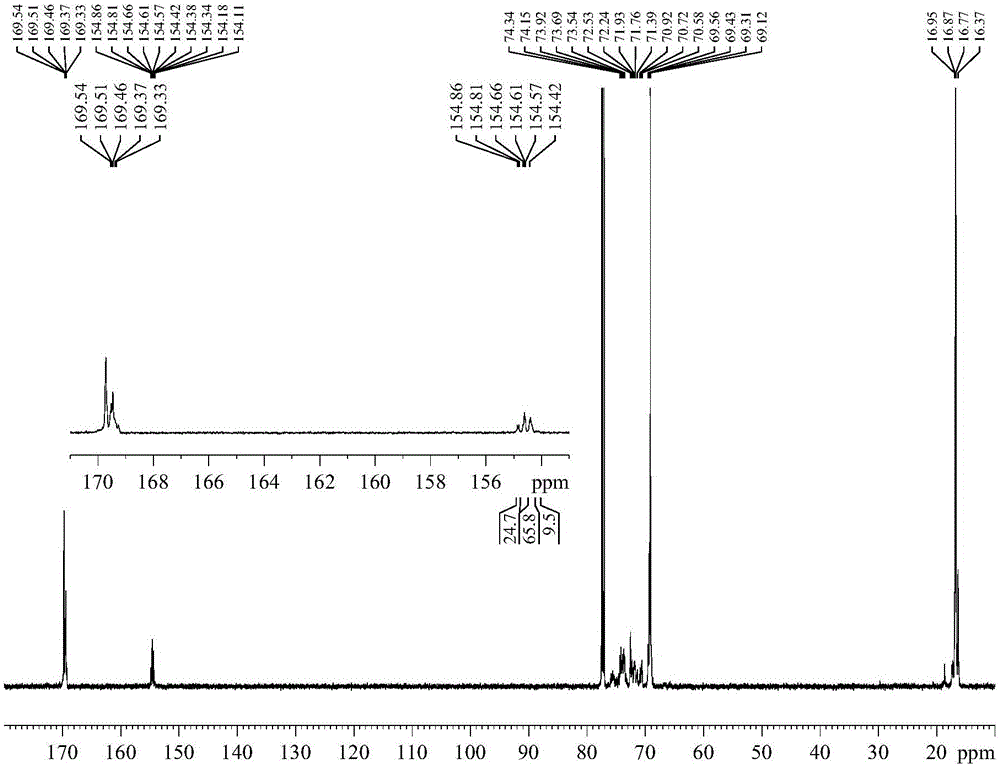

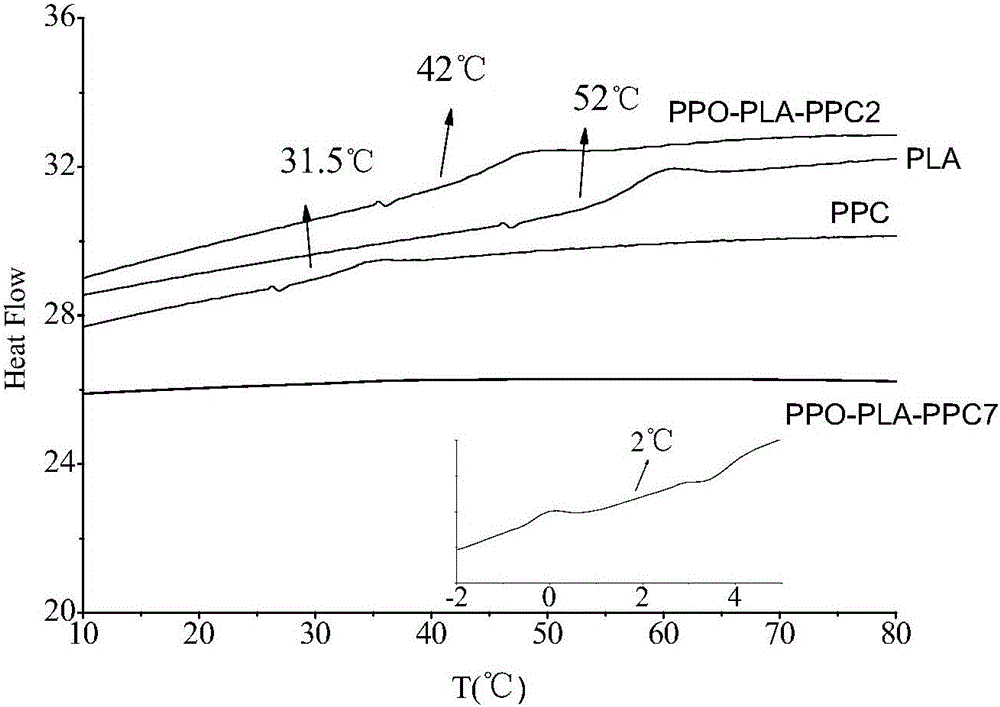

[0027]Add 22.7mg (0.036mmol) of the SalenCrCl catalyst shown in the above formula, 8.78mg (0.072mmol) of the promoter DMAP and 0.5mL of propylene oxide into the autoclave respectively (SalenCrCl catalyst: promoter: propylene oxide=1:2 :200 (molar ratio)), the polymerization reaction temperature is 60 ℃, after reacting for 12 hours, add lactide 1.037g (the molar ratio of lactide and propylene oxide is 1:1) and solvent dioxane 5mL After reacting for 2 hours, feed carbon dioxide into the autoclave to maintain the pressure in the kettle at 3MPa, and the reaction time was 18 hours. After the reaction, 100mL of methanol hydrochloride (HCl mass percentage concentration was 1%) was added to terminate the reaction, and the obtained The product was washed with a large amount of methanol, and dried in vacuum to obtain 1.6 g of white polyether-polylactide-aliphatic polycarbonate ternary block copolymer with a number-average molecular weight of 10,000 and a molecular weight dist...

Embodiment 2

[0030]

[0031] The SalenCo(OC shown in the above formula 6 h 3 (NO 2 ) 2 ) catalyst 29mg (0.035mmol), co-catalyst 2,6-lutidine 7.58mg (0.07mmol) and propylene oxide 12.2mL (175mmol) were added in the autoclave respectively (molar ratio SalenCo(OC 6 h 3 (NO 2 ) 2 ) Catalyst: co-catalyst: propylene oxide=1:2:5000), polymerization reaction temperature is 25 ℃, after reacting for 24 hours, add lactide 2.52g again (the mol ratio of lactide and propylene oxide is 1: 10) and solvent dichloromethane 10mL, after reacting for 6 hours, then rapidly charge carbon dioxide in the autoclave, the pressure in the autoclave is maintained at 1.5MPa, and the reaction time is 22 hours, add 100mL hydrochloric acid methanol (HCl mass hundred concentration is 1%) to terminate the reaction, the resulting product is washed with a large amount of methanol, and vacuum-dried to obtain 3.3 g of white polyether-polylactide-aliphatic polycarbonate ternary block copolymer, its number-average molecul...

Embodiment 3

[0033]

[0034] The SalenCr (OOCCF shown in the above formula 3 ) catalyst 23mg (0.035mmol), bis-(triphenylphosphoryl) ammonium chloride PPNCl 10mg (0.0175mmol) and propylene oxide 12.2mL (175mmol) were added in the autoclave respectively (molar ratio SalenCr(OOCCF 3 ) Catalyst: cocatalyst: propylene oxide=1:0.5:5000), polymerization reaction temperature is 60 ℃, after reacting for 10 hours, add lactide 0.504g again (the mol ratio of lactide and propylene oxide is 1: 50) of propylene oxide 5mL solution, after reacting for 6 hours, then quickly charge carbon dioxide in the autoclave, the pressure in the autoclave was maintained at 4.5MPa, and the reaction time was 22 hours. Add 100mL of methanol hydrochloride (HCl mass hundred concentration is 1%) to terminate the reaction, the resulting product is washed with a large amount of methanol, and vacuum-dried to obtain 0.6g of white polyether-polylactide-aliphatic polycarbonate ternary block copolymer, its number-average molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com