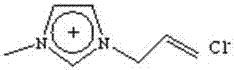

A kind of method for improving 1-allyl-3-methylimidazolium chloride dissolving cellulose performance

A methylimidazolium chloride salt and cellulose-dissolving technology, which is applied in the field of improving the cellulose-dissolving performance of 1-allyl-3-methylimidazolium chloride salt, can solve the problems of high-efficiency conversion and deep processing, long dissolution time, and solubility Low-level problems, to achieve the effect of increasing the concentration and ability of dissolution, reducing the dissolution time, and reducing the dissolution temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for improving the cellulose-dissolving performance of 1-allyl-3-methylimidazolium chloride salt, vacuum-drying microcrystalline cellulose with an average degree of polymerization of 265 at 50°C until the water content is less than 0.8%, adding to 1 -Allyl-3-methylimidazolium chloride salt, and then add solid acid-sulfonic acid ion exchange resin; stir at a temperature of 80°C and a mechanical stirring speed of 500rpm for 30min to completely dissolve. Wherein, the concentration of microcrystalline cellulose is 3wt%, the concentration of solid acid is 2.0wt%, the particle size of solid acid is 300 microns, and the resin exchange capacity is 4.2 eq / kg.

[0026] In the prior art, 1-allyl-3-methylimidazolium chloride salt dissolves microcrystalline cellulose (the average degree of polymerization is 265), the concentration of microcrystalline cellulose is 3 wt%, the temperature is 80°C, and the stirring speed is 500 rpm , the time required for microcrystalline cellul...

Embodiment 2

[0029] A method for improving the cellulose-dissolving performance of 1-allyl-3-methylimidazolium chloride salt, vacuum-drying cotton fibers with an average degree of polymerization of 2180 at 40°C until the water content is less than 0.8%, adding to 1-ene Propyl-3-methylimidazolium chloride, and then add solid acid-sulfonic acid ion exchange resin; dissolve at a temperature of 115°C and a mechanical stirring speed of 200rpm for 120min. Wherein, the quality of cotton fiber is 18wt% of 1-allyl-3-methylimidazolium chloride salt quality, the concentration of solid acid is 4.0wt%, the particle diameter of solid acid is 200 microns, and resin exchange capacity is 4.3 eq / kg.

[0030] In this example, the solubility of cotton fiber is 60.2%.

[0031] However, in the prior art, 1-allyl-3-methylimidazolium chloride salt dissolves cotton fibers (the average degree of polymerization is 2180), and the quality of cotton fiber is 100% of that of 1-allyl-3-methylimidazolium chloride salt. ...

Embodiment 3

[0034] A method for improving the performance of 1-allyl-3-methylimidazolium chloride salt dissolving cellulose, vacuum-drying eucalyptus wood dissolving pulp fibers with an average degree of polymerization of 520 at 30°C until the water content is less than 1%, adding to 1-allyl-3-methylimidazolium chloride salt, and then add solid acid-sulfonic acid ion exchange resin; at a temperature of 110°C, stir at a mechanical stirring speed of 800rpm for 90min to completely dissolve. Among them, the concentration of eucalyptus wood dissolving pulp fiber is 10wt%, the concentration of solid acid is 1.0wt%, the particle size of solid acid is 300 microns, and the resin exchange capacity is 4.5 eq / kg. The dissolved 1-allyl-3-methylimidazolium chloride salt is recovered by the solvent system and continues to be reused in the dissolution system. After 5 cycles of use, the recovery rate of 1-allyl-3-methylimidazolium chloride salt is was 97%, and the loss rate was 3.0%.

[0035] In the prio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com