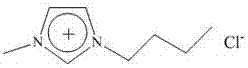

A method for improving 1-butyl-3-methylimidazolium chloride salt dissolving cellulose performance

A methylimidazolium chloride salt and cellulose-dissolving technology, which is applied in the field of improving the cellulose dissolving performance of 1-butyl-3-methylimidazolium chloride salt, can solve the problem that the cellulose dissolving performance is not very good, which hinders efficient conversion and deep Processing, solvents are difficult to recycle, etc., to achieve the effect of improving solubility, increasing solubility concentration and ability, and reducing dissolution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for improving the cellulose dissolving performance of 1-butyl-3-methylimidazole chloride salt. The microcrystalline cellulose with an average degree of polymerization of 230 is vacuum dried at 50°C until the water content is less than 0.5%. 99.0% of 1-butyl-3-methylimidazole chloride salt, and then add solid acid-sulfonic acid ion exchange resin; at a temperature of 80 ℃, mechanical stirring speed 500rpm stirring for 25min to completely dissolve. Among them, the concentration of microcrystalline cellulose is 3 wt%, the concentration of solid acid is 2.0 wt%, the particle size of solid acid is 300 microns, and the resin exchange capacity is 4.2 eq / kg.

[0028] In the prior art, 1-butyl-3-methylimidazole chloride salt dissolves microcrystalline cellulose (average degree of polymerization is 230), the microcrystalline cellulose concentration is 3 wt%, the temperature is 80°C, and the stirring speed is 500 rpm. The time required for the complete dissolution of microcr...

Embodiment 2

[0031] A method for improving the cellulose dissolving performance of 1-butyl-3-methylimidazole chloride salt, vacuum drying cotton fiber with an average degree of polymerization of 2180 at 40°C, until the moisture content is less than 0.8%, and adding to the purity of 98.0% The solid acid-sulfonic acid ion exchange resin is added to the 1-butyl-3-methylimidazole chloride salt; the temperature is 120°C and the mechanical stirring speed is 200rpm for 120min to dissolve. Among them, the mass of cotton fiber is 20wt% of the mass of 1-butyl-3-methylimidazole chloride, the concentration of solid acid is 4.0wt%, the particle size of solid acid is 200 microns, and the resin exchange capacity is 4.3 eq / kg .

[0032] In this example, the solubility of cotton fiber is 56.1%.

[0033] In the prior art, 1-butyl-3-methylimidazole chloride salt dissolves cotton fiber (average degree of polymerization is 2180), and the mass of cotton fiber is 20wt% of the mass of 1-butyl-3-methylimidazole chlori...

Embodiment 3

[0036] A method for improving the cellulose dissolving performance of 1-butyl-3-methylimidazole chloride salt. The eucalyptus wood dissolving pulp fiber with an average degree of polymerization of 560 is vacuum dried at 30°C to a water content of less than 1%, and then added to 1 -Butyl-3-methylimidazole chloride salt, and then add solid acid-sulfonic acid ion exchange resin; at a temperature of 110°C, a mechanical stirring speed of 800rpm, stirring for 90min, completely dissolved. Among them, the concentration of eucalyptus dissolving pulp fiber is 10 wt%, the concentration of solid acid is 1.0 wt%, the particle size of solid acid is 300 microns, and the resin exchange capacity is 4.5 eq / kg. The dissolved 1-butyl-3-methylimidazole chloride salt is recovered by the solvent system and is reused in the dissolution system. After 5 cycles of use, the recovery rate of 1-butyl-3-methylimidazole chloride salt is 96.8 %, the loss rate is 3.2%.

[0037] In the prior art, 1-butyl-3-methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com