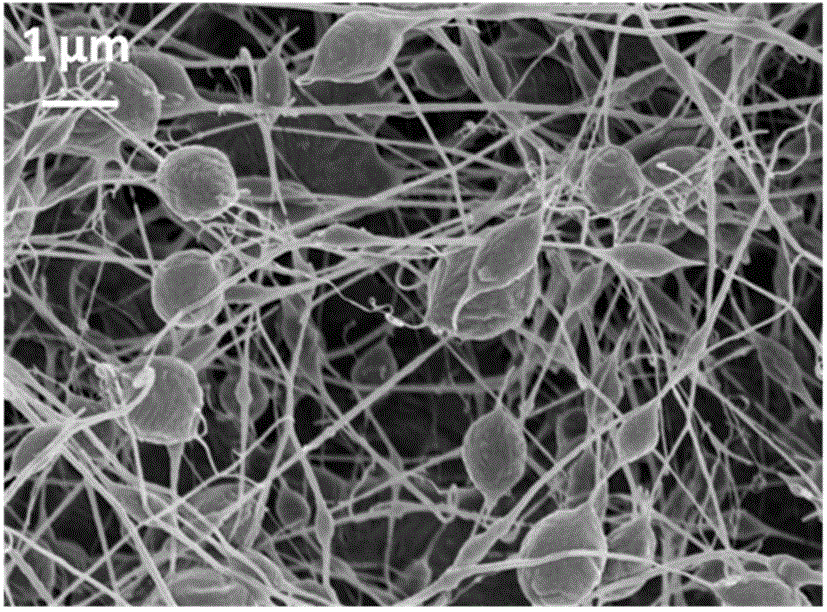

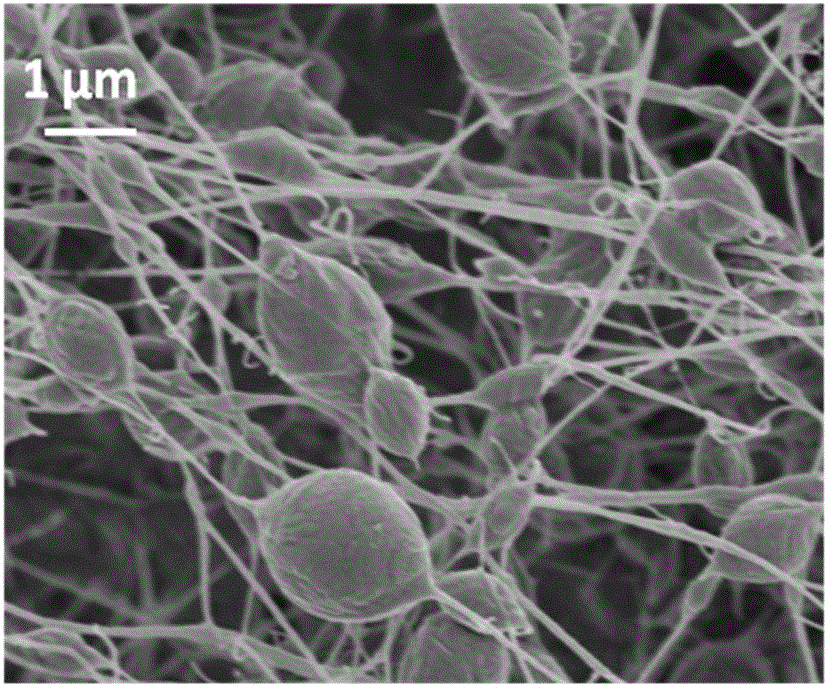

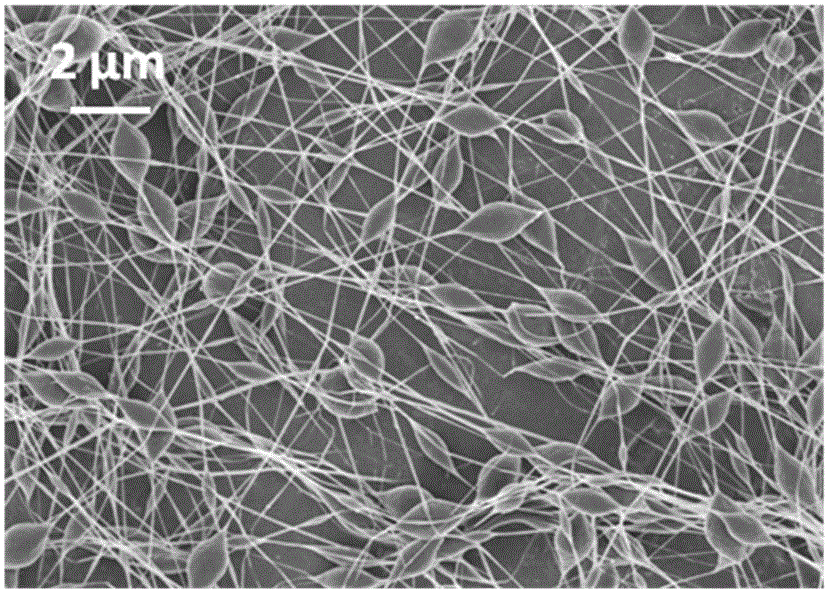

Beaded ultrafine fiber material with bead morphology and preparation method thereof

A fiber material and bead technology, which is applied in the field of micro-nano material preparation, can solve problems such as bead morphology and size regulation, and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Dissolve 25.44 g of sodium carbonate in 12 L of boiling deionized water, add 30 g of silk, stir for 30-40 min, and then wash the degummed silk fibroin five times with normal temperature deionized water. Spread the washed silk fibroin on an aluminum foil paper, and put it in a 60°C oven to dry for 24 hours.

[0025] 2. Take out the dried silk fibroin, and dissolve the silk fibroin with 76 mL of 9.3 mol / L lithium bromide solution. When dissolving, lithium bromide solution and silk fibroin should be put into the beaker alternately, then sealed with plastic film, put in a 60°C oven for 4-5 hours, and shake once every 30 minutes.

[0026] 3. Put the lithium bromide solution of the obtained silk fibroin into a dialysis bag, dialyze with deionized water to remove impurities such as lithium bromide, and centrifuge at 9000 r / min for 20 min with a high-speed centrifuge to obtain a pure silk fibroin solution. At this point the concentration of the solution is about 7 wt%.

[...

Embodiment 2

[0032]1. Put 1 kg of cocoon shells into 50 liters of 0.5 wt% sodium carbonate solution, treat them at 98-100°C for 2 hours to degumming the cocoon shells, and obtain pure silk fibroin after fully washing. The pure silk fibroin after drying with 5 liters of lithium bromide aqueous solution of 9.3 mol / L, at 65 + Stir to dissolve at 2°C.

[0033] 2. Using cellulose membrane as the dialysis material, dialyze the obtained lithium bromide solution of silk fibroin with deionized water to remove impurities such as lithium bromide, and centrifuge at 9000 r / min for 20 minutes in a high-speed centrifuge to obtain pure silk fibroin protein solution.

[0034] 3. Put the silk fibroin solution in an oven at 60°C until the volume is reduced by half, then slowly concentrate the solution in a fume hood to make the concentration higher than 20 wt%, and then dilute the solution with deionized water, Make the concentration 0.5 wt%, stir evenly, seal and place in an oven at 60 °C until a gel cont...

Embodiment 3

[0040] 1. Put 200 grams of silk into 10 liters of 0.3% sodium carbonate aqueous solution, and treat it at 98-100°C for 2 hours to degumming the silk, and obtain pure silk fibroin after fully washing. With the dried pure silk fibroin, with 100 milliliters of 9.3 mol / L lithium bromide aqueous solution at 65 + Stir to dissolve at 2°C.

[0041] 2. Using cellulose membrane as the dialysis material, dialyze the obtained lithium bromide solution of silk fibroin with deionized water to remove impurities such as lithium bromide, and centrifuge at 9000 r / min for 20 minutes in a high-speed centrifuge to obtain pure silk fibroin protein solution.

[0042] 3. Put the silk fibroin solution in an oven at 60°C until the volume is reduced by half, then slowly concentrate the solution in a fume hood to make the concentration higher than 20 wt%, and then dilute the solution with deionized water, Make the concentration 1 wt%, stir evenly, seal and place in an oven at 60°C until a gel containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com