Two-dimensional porous carbon skeletal nano-material and preparation method thereof

A nano-framework, porous carbon technology, applied in chemical instruments and methods, secondary batteries, catalysts for physical/chemical processes, etc. The effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

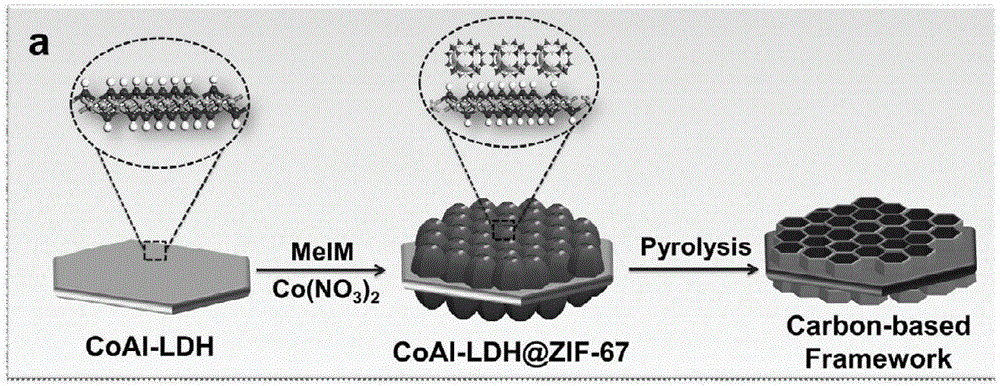

[0022] Synthesis of two-dimensional porous carbon nanoskeleton materials on the surface of cobalt aluminum hydrotalcite:

[0023] a: get 0.1 cobalt aluminum hydrotalcite and disperse in 50mL methanol solution;

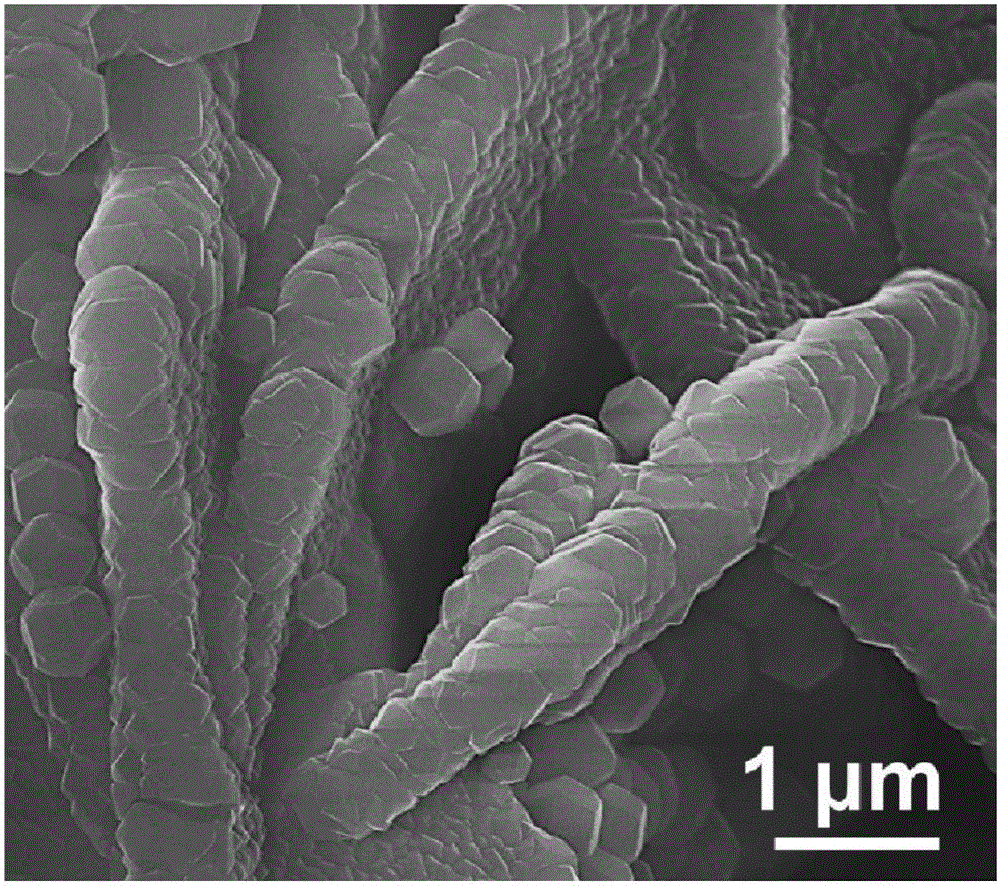

[0024] b: Dissolving 1 g of cobalt nitrate and 8 g of 1,2-dimethylimidazole in the methanol solution dispersed with cobalt-aluminum hydrotalcite, centrifuging, washing, and drying after magnetic stirring for 30 min at room temperature;

[0025] c: put the product obtained in step b into an atmosphere furnace, and continuously roast at 800° C. for 2 hours under the protection of nitrogen, wherein the heating rate is 2° C. / min.

[0026] The divalent metal ion of the cobalt aluminum hydrotalcite is Co 2+ , the trivalent metal ion is Al 3+ , the molar ratio of cobalt to aluminum is 2:1.

[0027] The specific surface area of the two-dimensional porous carbon nano-skeleton material prepared above is 325m 2 g -1 , the sheet diameter is 6μm, and the thickness is 500nm. ...

Embodiment 2

[0029] Synthesis of two-dimensional porous carbon nanoskeleton materials on the surface of zinc aluminum hydrotalcite:

[0030] a: Get 0.1 zinc aluminum hydrotalcite and disperse it in 50mL ethanol solution;

[0031] b: 1g of zinc nitrate and 3g of trimesic acid were dissolved in the above-mentioned ethanol solution dispersed with zinc-aluminum hydrotalcite, centrifuged, washed and dried after magnetic stirring for 10min at room temperature;

[0032] c: put the product obtained in step b into an atmosphere furnace, and continuously roast at 700° C. for 2 hours under the protection of nitrogen, wherein the heating rate is 2° C. / min.

[0033] The divalent metal ion of the zinc-aluminum hydrotalcite is Zn 2+ , the trivalent metal ion is Al 3+ , the molar ratio of zinc to aluminum is 2:1.

Embodiment 3

[0035] Synthesis of two-dimensional porous carbon nanoskeletons on the surface of cobalt-iron hydrotalcite:

[0036] a: Get 0.5 cobalt iron hydrotalcite and disperse it in 50mL methanol solution;

[0037] b: Dissolve 0.5 g of ferric nitrate and 8 g of 1,2-dimethylimidazole in the above-mentioned methanol solution dispersed with cobalt-iron hydrotalcite, centrifuge, wash and dry after magnetic stirring for 30 min at room temperature;

[0038] c: put the product obtained in step b into an atmosphere furnace, and continuously roast at 800° C. for 2 hours under the protection of nitrogen, wherein the heating rate is 2° C. / min.

[0039] The divalent metal ion of the cobalt-iron hydrotalcite is Co 2+ , the trivalent metal ion is Fe 3+ , the molar ratio of cobalt to iron is 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com