Nano epoxy high hydrogen bubble water as well as preparation device and preparation method thereof

A preparation device and technology for hydrogen bubbles, applied in chemical instruments and methods, mixing methods, water treatment parameter control, etc., can solve the problems of difficulty in storage, low hydrogen solubility, etc., achieving strong practicability, increasing dissolved oxygen, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

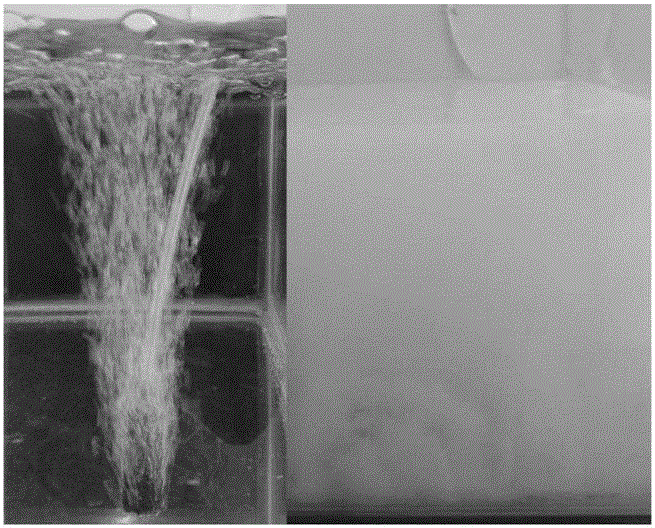

Image

Examples

Embodiment 1

[0043] The invention relates to nano-reoxidation high-hydrogen bubble water, wherein the hydrogen concentration in the nano-reoxidation high-hydrogen bubble water is 3-5ppm.

[0044] The preparation method is as follows:

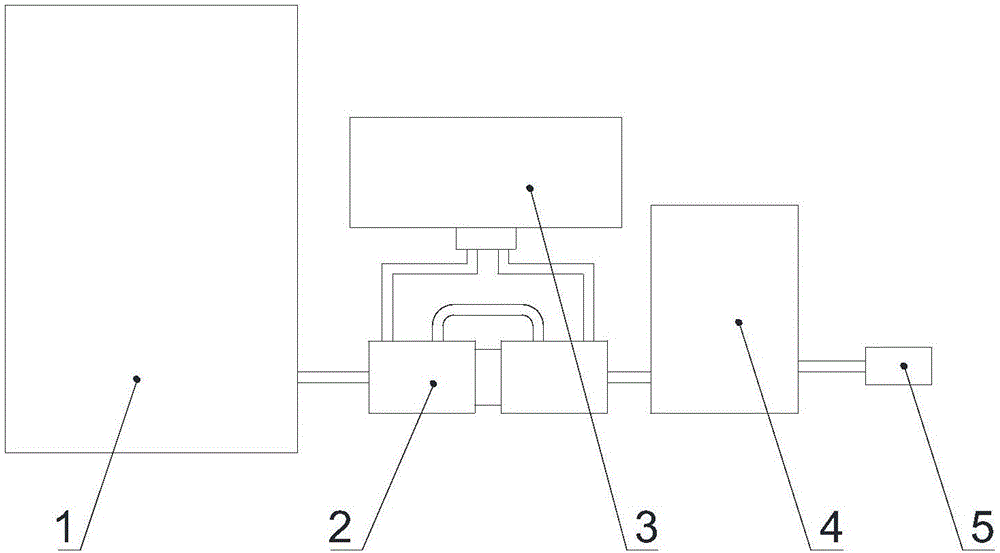

[0045] Step 1: Vacuumize the premixed water storage tank 1 and stir the drinking water to remove the gas in the drinking water;

[0046] Step 2: filling the premixed water storage tank 1 with hydrogen gas and stirring the drinking water, so that the hydrogen gas and the drinking water are premixed to obtain a primary gas-water mixture;

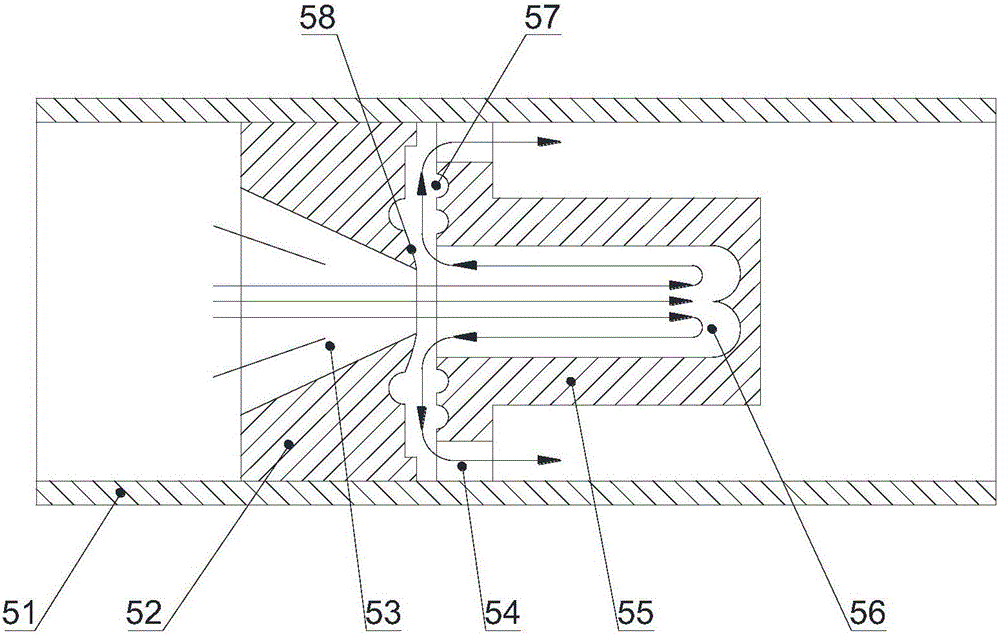

[0047] Step 3: Transport the primary gas-water mixture obtained in step 2 to the secondary gas-liquid mixing pump 2, and fill the secondary gas-liquid mixing pump 2 with hydrogen, so that the premixed gas-water mixture is further mixed with hydrogen to form Secondary gas-water mixture;

[0048] Step 4: inject the secondary gas-water mixture obtained in step 3 into the pressure tank 4 to pressurize the gas-water mixture;

...

Embodiment 2

[0057] The invention relates to nano-reoxidized high-hydrogen bubble water, wherein the oxidation-reduction potential OR of the nano-reduced oxygen-rich high-hydrogen bubble water is -900 to -1200mv.

[0058] The preparation method is as follows:

[0059] Step 1: Vacuumize the premixed water storage tank 1 and stir the drinking water to remove the gas in the drinking water;

[0060] Step 2: filling the premixed water storage tank 1 with hydrogen gas and stirring the drinking water, so that the hydrogen gas and the drinking water are premixed to obtain a primary gas-water mixture;

[0061] Step 3: Transport the primary gas-water mixture obtained in step 2 to the secondary gas-liquid mixing pump 2, and fill the secondary gas-liquid mixing pump 2 with hydrogen, so that the premixed gas-water mixture is further mixed with hydrogen to form Secondary gas-water mixture;

[0062] Step 4: inject the secondary gas-water mixture obtained in step 3 into the pressure tank 4 to pressurize...

Embodiment 3

[0071] A kind of bottled water, comprising the nano red oxygen high hydrogen sparkling water described in any one of embodiment 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com