Method for treating manganese-containing wastewater

A treatment method and wastewater technology, which is applied in metallurgical wastewater treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of non-direct discharge, increased operating cost, high cost, etc., and achieve less raw material consumption and manganese removal The effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

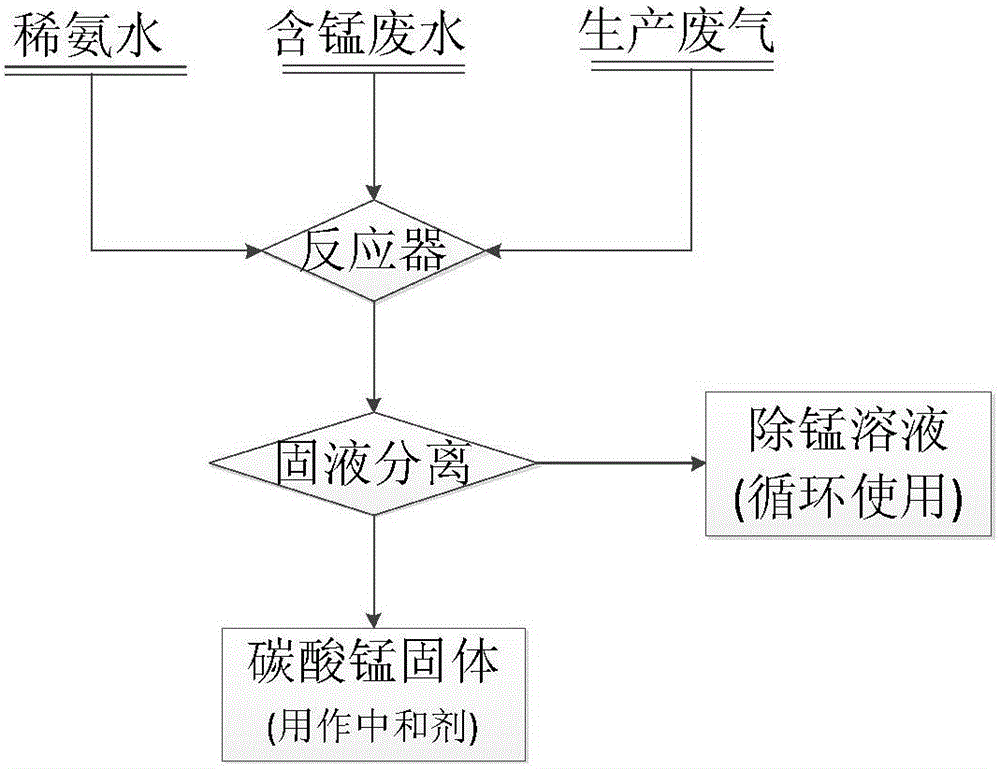

[0028] A kind of processing method of manganese-containing waste water of the present invention, process flow chart is as figure 1 shown, including the following steps:

[0029] (1) Determination of Mn in the manganese-containing waste water to be treated (washing water produced in the electrolytic manganese process) 2+ The concentration is 200mg / L;

[0030] (2) Get 200L of manganese-containing wastewater to be treated and put it into the reactor, then add 360mL of ammoniacal liquor with a concentration of 17%, and adjust the pH value of the manganese-containing wastewater to 6.5;

[0031] (3) Under the condition of stirring, in the manganese-containing waste water after step (2) process, pass into the electrolytic manganese production process and adopt the sulfuric acid leaching to produce containing CO 2 exhaust gas (CO in the exhaust gas 2 Concentration is 10%), the flow velocity of feeding waste gas is 20L / min, the time of feeding gas is 85min (the feeding amount of car...

Embodiment 2

[0033] A treatment method for manganese-containing wastewater of the present invention, comprising the following steps:

[0034] (1) Determination of Mn in the manganese-containing waste water to be treated (washing water produced in the electrolytic manganese process) 2+ The concentration is 4200mg / L;

[0035] (2) Get 200L of manganese-containing wastewater to be treated and add it to the reactor, then add 1709g quicklime to adjust the pH value of the manganese-containing wastewater to 7.5;

[0036] (3) Under the condition of stirring, in the manganese-containing waste water after the step (2) is processed, pass into the CO containing CO produced by the boiler combustion 2 exhaust gas (CO in the exhaust gas 2 Concentration is 8%), the flow velocity of passing into waste gas is 100L / min, the time of passing into gas is 214min (the feeding amount of carbon dioxide is 5 times of theoretical amount), after the reaction is finished, the solution is carried out using vacuum sucti...

Embodiment 3

[0038] A treatment method for manganese-containing wastewater of the present invention, comprising the following steps:

[0039] (1) Determination of Mn in the manganese-containing waste water to be treated (slag field permeate in the electrolytic manganese process) 2+ The concentration is 25000mg / L;

[0040] (2) Get 200L of manganese-containing wastewater to be treated and add it to the reactor, add 10L of ammonia water with a concentration of 17%, and then add 7462g of quicklime in batches to adjust the pH value of the manganese-containing wastewater to 7.8;

[0041] (3) Under the condition of stirring, in the manganese-containing waste water after the step (2) is processed, pass into the CO containing CO produced by the boiler combustion 2 waste gas (the feed rate of carbon dioxide is 1.5 times of theoretical amount), after the reaction finishes, the solution is carried out solid-liquid separation using a thickener to obtain manganese carbonate solid and manganese removal so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com