Cement hollow brick capable of releasing negative ions and preparation method thereof

A kind of hollow brick, negative ion technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

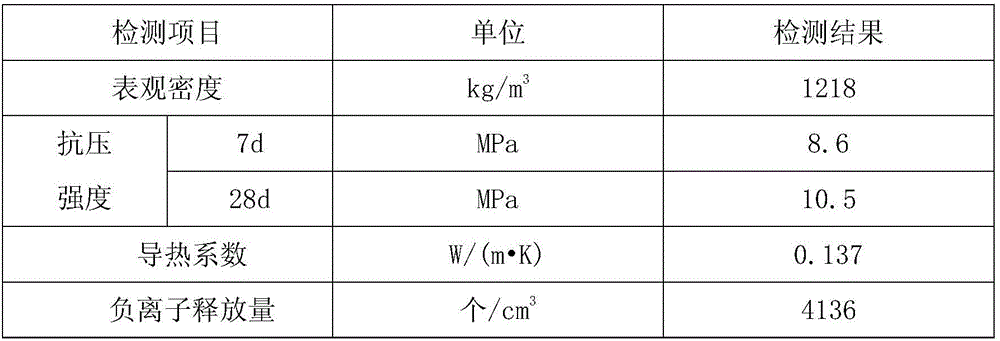

Image

Examples

Embodiment Construction

[0014] A cement hollow brick capable of releasing negative ions, made of the following raw materials (kg): high-calcium lime 9, shell powder 7, refining slag 11, sea mud 19, polyethylene glycol 8, high-silicon iron tailings 12, Waste molding sand 18, volcanic tuff 7, high temperature activated bamboo charcoal powder 5, oil shale slag 15, phosphate cement 64, calcium gluconate 6, osmanthus gemstone 16, apatite 12, crystal salt rock gravel 14, propylene glycol alginate 7. Barite 18, cement slag 11, appropriate amount of water.

[0015] A kind of preparation method of the cement hollow brick that can release negative ion, comprises the following steps:

[0016] (1) Mix cement slag, apatite, sea mud, and high-silicon iron tailings evenly, crush them, pass through a 120-mesh sieve, add an appropriate amount of water, stir well, make balls, control the particle size at 3mm, and then make The raw meal balls were dried at 115°C until the moisture content was below 1%, and then the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com