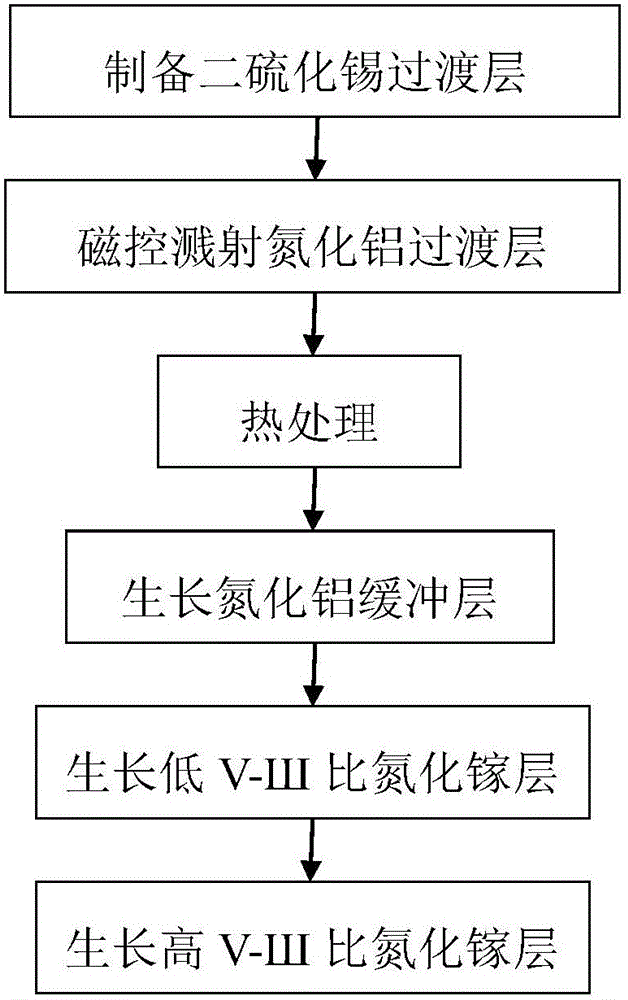

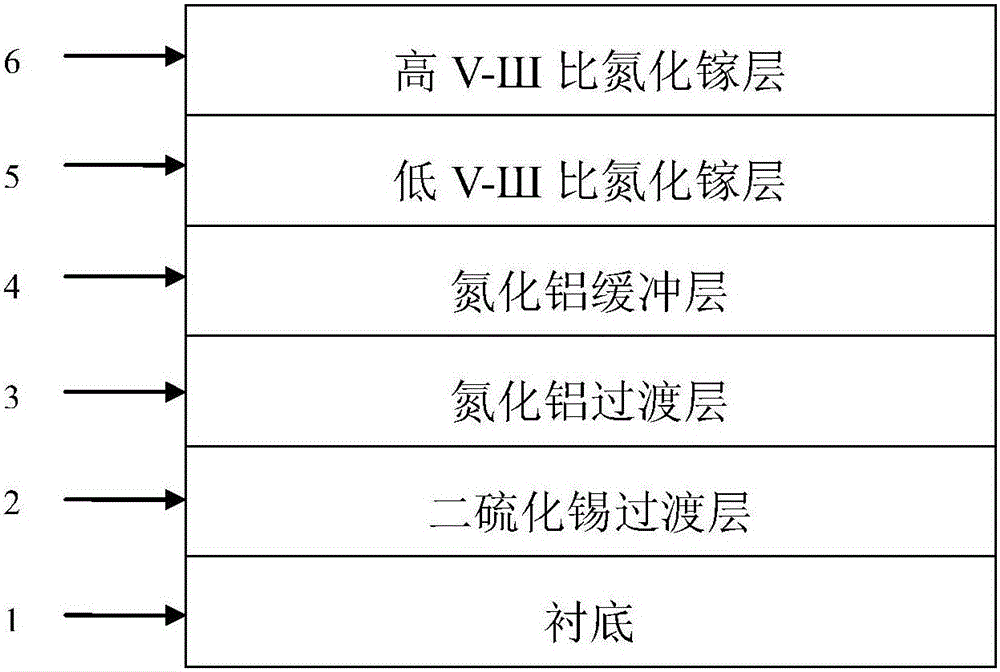

Gallium nitride growth method based on tin disulfide and magnetron sputtering aluminium nitride

A technology of tin disulfide and magnetron sputtering, which is applied in the field of electronics, can solve problems such as mismatch, large lattice, and difficulty in effectively alleviating substrate lattice mismatch, and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: Ga-surface gallium nitride film based on tin disulfide and magnetron sputtering aluminum nitride.

[0053] Step 1. Prepare a tin disulfide transition layer.

[0054] First wash the four quartz ampoules A, B, C, and D with 10% hydrofluoric acid and then dry them thoroughly. Put the tin particles into the A quartz ampoule. The purity of the tin particles is 99.9%, and the amount of the substance is 4.08 mg. mol; the sulfur crystals are placed in the B quartz ampoule, the purity of the sulfur crystals is 99.9%, and the amount of the substance is 8.15 mmol; the iodine particles are placed in the C quartz ampoule, the purity of the iodine particles is 99.9%, and the mass is 2.0 per unit volume ~3.0 mg; four quartz ampoules A, B, C, D were then sealed. Put the three quartz ampoules A, B, and C into the front section of the two-stage quartz reaction furnace, put the D quartz ampoule into the back section of the two-stage quartz reaction furnace and open the four...

Embodiment 2

[0066] Embodiment 2: N-face gallium nitride film based on tin disulfide and magnetron sputtering aluminum nitride.

[0067] Step A. Preparation of tin disulfide transition layer:

[0068] First wash the four quartz ampoules A, B, C, and D with 10% hydrofluoric acid and then dry them thoroughly. Put the tin particles into the A quartz ampoule. The purity of the tin particles is 99.9%, and the amount of the substance is 4.08 mg. mol; the sulfur crystals are placed in the B quartz ampoule, the purity of the sulfur crystals is 99.9%, and the amount of the substance is 8.15 mmol; the iodine particles are placed in the C quartz ampoule, the purity of the iodine particles is 99.9%, and the mass is 2.0 per unit volume ~3.0 mg; four quartz ampoules A, B, C, D were then sealed. Put the three quartz ampoules A, B, and C into the front section of the two-stage quartz reaction furnace, put the D quartz ampoule into the back section of the two-stage quartz reaction furnace and open the fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com