Growing method of ultraviolet LED active area multiple quantum well

A technology of multiple quantum wells and growth methods, which is applied in the field of growth of multiple quantum wells in the active area of ultraviolet LEDs, can solve the problems of reducing the luminous efficiency of quantum wells, and achieves optimal concentration distribution, increased current injection efficiency, and reduced stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

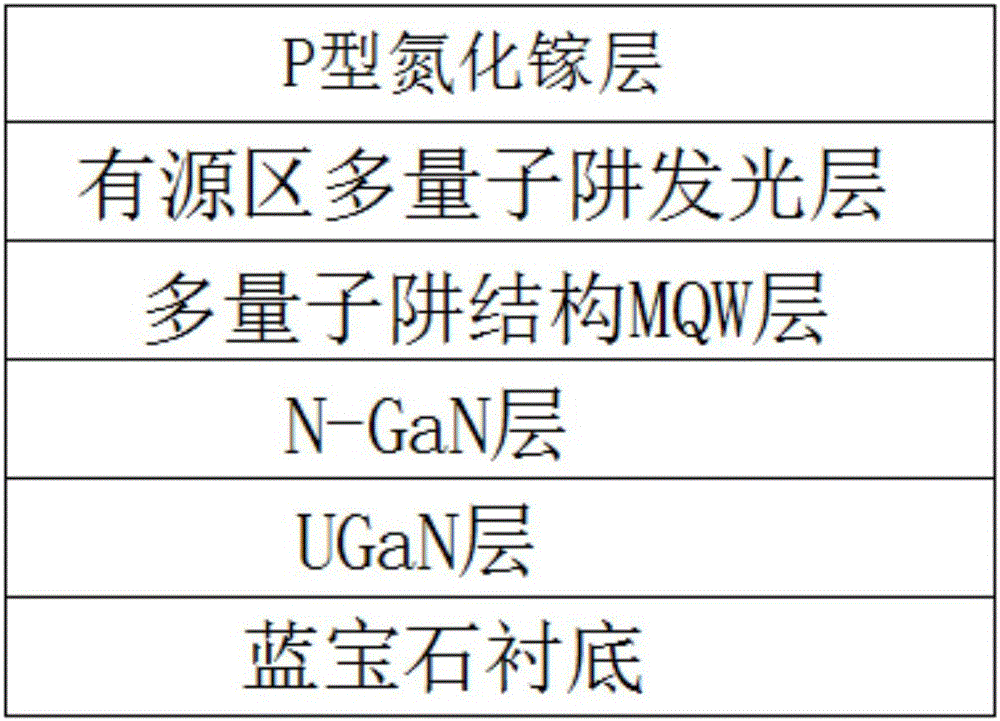

[0019] A method for growing multi-quantum wells in the active region of an ultraviolet LED. The epitaxial structure of the LED chip is in the order from bottom to top: sapphire substrate, UGaN layer, N-GaN layer, multi-quantum well structure MQW layer, active A multi-quantum well light-emitting layer and a p-type gallium nitride layer, the growth method of which comprises the following steps:

[0020] Step 1: On the sapphire substrate, adjust the temperature to 1000-1200°C, pass through TMGa, grow a UGaN layer with a thickness of 0.5-2.5um, the growth pressure is between 100-500Torr, V / III molar ratio Between 300-2500;

[0021] Step 2, after the growth of the UGaN layer is completed, grow a layer of N-GaN layer with a stable doping concentration, the thickness is 1.5-4.5um, the growth temperature is between 1000-1200°C, and the pressure is between 100-600Torr, V / Ⅲ molar ratio between 50-2000;

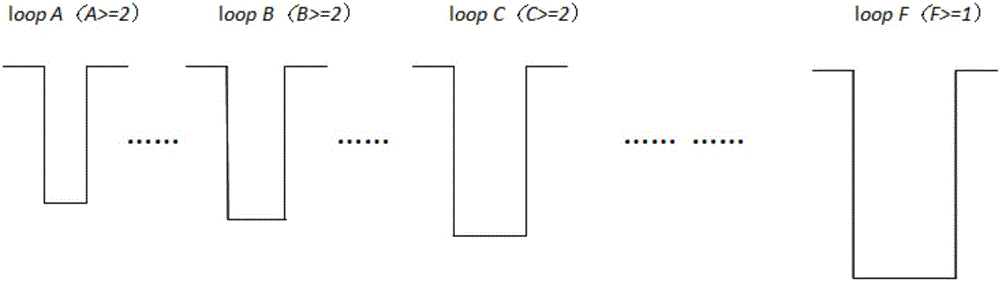

[0022] Step 3, after the growth of the N-GaN layer is completed, grow the multi-...

Embodiment 2

[0027] A method for growing multiple quantum wells in an active region of an ultraviolet LED, the growth method comprising the following steps:

[0028] Step 1: On the sapphire substrate, adjust the temperature to 1100°C, inject TMGa, and grow a UGaN layer with a thickness of 1.5um, the growth pressure is 300 Torr, and the V / III molar ratio is 500;

[0029] Step 2, after the growth of the UGaN layer is completed, a layer of N-GaN layer with a stable doping concentration is grown, the thickness is 2.5um, the growth temperature is 1100°C, the pressure is 300Torr, and the V / III molar ratio is 500;

[0030]Step 3, after the growth of the N-GaN layer is completed, grow the multi-quantum well structure MQW layer, the growth temperature is 800 ° C, the growth pressure is 300 Torr, the V / III molar ratio is 2000, and the multi-quantum well structure MQW layer is composed of 1 -20 layers In x Ga 1-X It consists of N / GaN multiple quantum wells, the thickness of the multiple quantum wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com