Artificial blood vessel

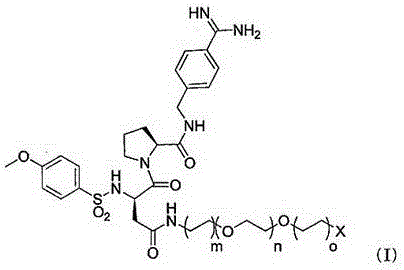

A technology of artificial blood vessels and blood, which is applied in the direction of blood vessels, human tubular structure devices, anticoagulant treatment, etc., and can solve the problems of promoting thrombus formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

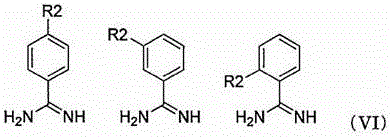

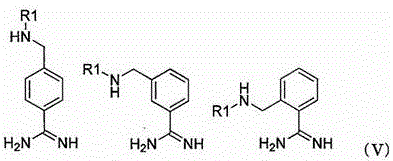

Method used

Image

Examples

Embodiment 1

[0249] As the warps and wefts constituting the inner tubular fabric, polyethylene terephthalate multifilament yarns having a single yarn fineness of 0.23 dtex, a total fineness of 33 dtex, and 144 filaments were used. In addition, as the warp yarns constituting the outer layer tubular fabric, a polyethylene terephthalate multifilament yarn with a single yarn fineness of 2.33 dtex, a total fineness of 56 dtex, and 24 filaments was used. For the weft yarn, polyethylene terephthalate monofilament yarn with a single yarn denier of 33 dtex was used. The warp was set on a dobby / double-shuttle loom (slim ドビー・シャトル 2-Ding loom), and the weft was woven so that the inner diameter became 3 mm. The scouring was performed at 98° C., and the heat setting was performed at 170° C. to obtain a multiple tubular fabric structure 1 .

[0250] Then, the tubular fabric 1 was immersed in an aqueous solution of 5.0 wt % potassium permanganate (manufactured by Wako Pure Chemical Industries, Ltd.) and ...

Embodiment 2

[0256] As the weft yarns constituting the inner tubular fabric, untwisted sea-island composite fibers with a single yarn fineness of 7.3 dtex and a total fineness of 66 dtex (sea / island (weight ratio) = 20 / 80 composite ratio, and island fraction of 70) were used. ) multifilament yarn, after refining, the sea component was completely dissolved in an aqueous solution of 4 wt% sodium hydroxide (manufactured by Wako Pure Chemical Industries, Ltd.) at 98°C, and further heat-setting was performed to form a single yarn fineness of 0.084 dtex, Except for the polyethylene terephthalate multifilament yarn having a total fineness of 53 dtex and 630 filaments, the same operation as in Example 1 was performed, and a multi-tubular fabric structure 2 was obtained.

[0257] Here, in the sea-island composite fiber, the island component polymer is composed of polyethylene terephthalate multifilament yarn, and the sea component polymer is composed of polyethylene terephthalate copolymerized with ...

Embodiment 3

[0261] As the warp and weft constituting the inner layer tubular fabric, the multifilament yarn as the sea-island composite fiber used in Example 2 was used, and after refining, 4 wt % sodium hydroxide (manufactured by Wako Pure Chemical Industries, Ltd. ) in the aqueous solution of ) to completely dissolve the sea component, and further heat-setting was performed to form a polyethylene terephthalate multifilament yarn with a single yarn fineness of 0.084 dtex, a total fineness of 53 dtex, and 630 filaments. The same operation as in Example 1 was carried out, and the multi-tubular fabric structure 3 was obtained by weaving.

[0262] The same operation as in Example 1 was performed on the obtained multiple tubular fabric structure 3 to obtain an artificial blood vessel (sample 3) in which the antithrombotic material layer was formed.

[0263] About the obtained artificial blood vessel (Sample 3), blood leakage evaluation, antithrombotic evaluation and cell affinity evaluation w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com