Catalytic cracking CO combustion improver and preparation method thereof

A technology of catalytic cracking and combustion aids, which is applied in the direction of catalytic cracking, cracking, and petroleum industry, and can solve the problems of reducing flue gas, high prices of combustion aids, and unfavorable large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

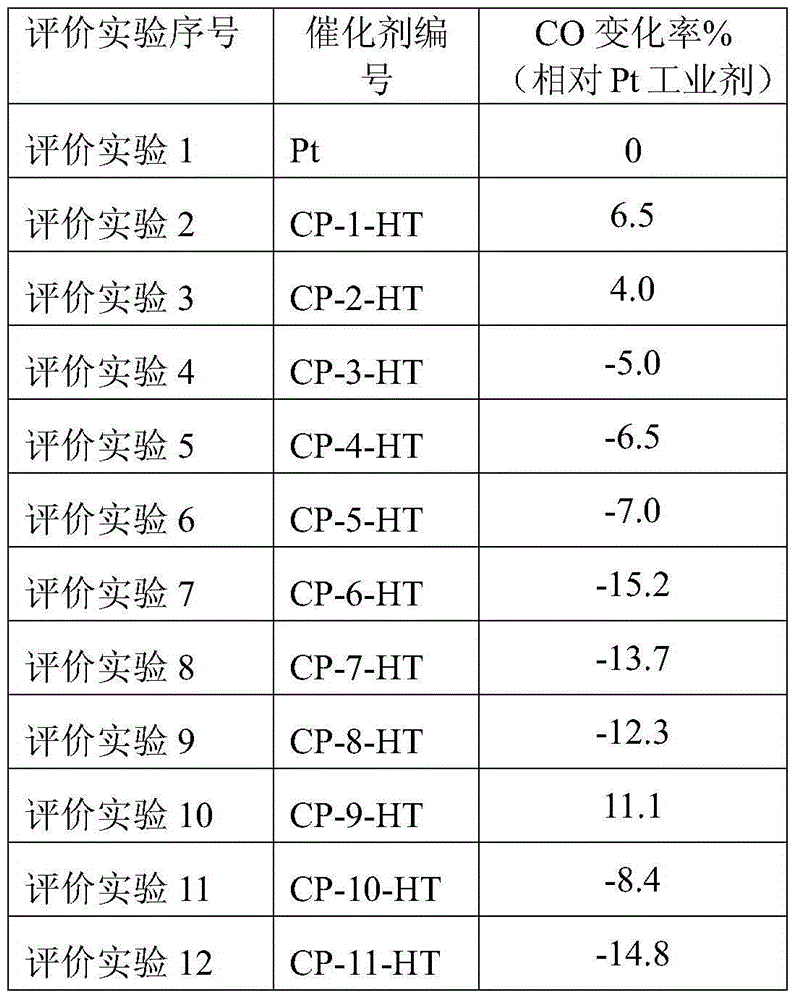

Examples

Embodiment 1

[0043] Example 1 This example illustrates the catalyst CP-1 of the present invention and its preparation method.

[0044] The first step is to prepare carrier alumina. Add 4870g of boehmite, 805g of hydrochloric acid, and 3824g of aluminum sol in 10500g of deionized water. After being fully dispersed by a homogenizer, a slurry 1 with a solid content of 19.3wt% is obtained; granules, and calcined at 550°C for 6 hours to obtain microspherical alumina carrier A, the specific surface area measured by BET method is 192m 2 / g, and the water absorption rate is 0.60g / ml. The catalyst carriers prepared in the present invention are all carrier A prepared by this method.

[0045] In the second step, weigh Ce(NO 3 ) 3 Solution 61.2g, La(NO 3 ) 3 Solution 10.93g, citric acid 28.8g, then add a small amount of water to a volume of 114ml; then add carrier A 189g, let it stand for adsorption saturation, put it in an oven at 100°C for 4h, and roast it in air at 500°C for 6h to obtain the ...

Embodiment 2

[0046] Embodiment 2 This embodiment illustrates catalyst CP-2 of the present invention and preparation method thereof

[0047] The carrier A prepared in Example 1 was directly used as the catalyst carrier. Weigh Ce(NO 3 ) 3 Solution 61.2g, Nd(NO 3 ) 3 10.85g of solution, 28.8g of citric acid, and then add a small amount of water to make the volume 114ml; then add 189g of carrier A, let it stand for adsorption saturation, dry it in an oven at 120°C for 1h, and roast it in air at 650°C for 2h to get Catalyst CP-2.

Embodiment 3

[0048] Embodiment 3 This embodiment illustrates catalyst CP-3 of the present invention and its preparation method

[0049] The carrier A prepared in Example 1 was directly used as the catalyst carrier. Weigh Ce(NO 3 ) 3 Solution 61.2g, Sm(NO 3 ) 3 Solution 10.85g, citric acid 28.8g, then add a small amount of water to make the volume 114ml; then add carrier A 189g, let it stand for adsorption saturation, put it in an oven at 110°C for 2h, and roast it in air at 550°C for 4h to get the catalyst CP-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap