Fluorescent high-polymer composite and preparation methods thereof

A technology of polymers and complexes, applied in coating and other directions, can solve the problems of reducing photothermal stability and mechanical strength of polymer complexes, reducing fluorescence detection sensitivity, short fluorescence emission wavelength, etc., and achieving excellent fluorescence characteristics, compounding Excellent effect, the effect of enhanced fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

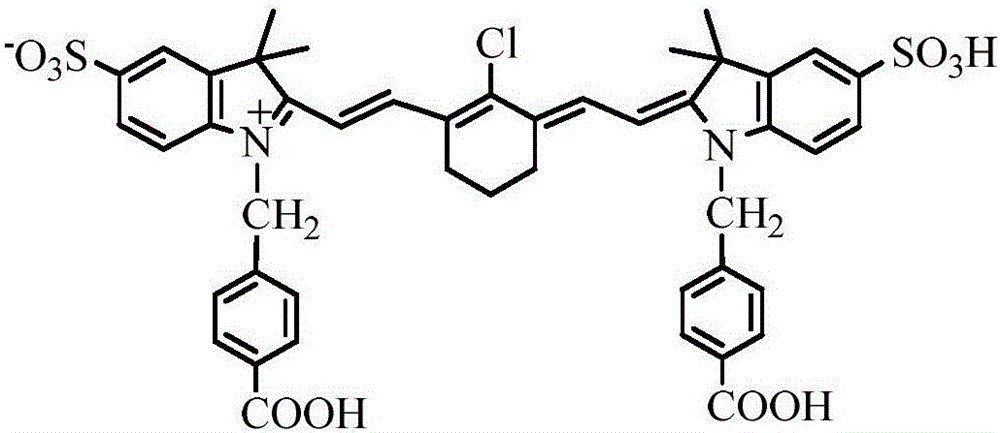

[0045] Dissolve 0.01 g of PVA in 9.99 g of deionized water, heat to 85° C., fully dissolve, and cool to room temperature to obtain 10 mL of a PVA aqueous solution with a mass fraction of 0.1 wt%. The indocyanine dye D1 (see molecular structure figure 1 ) Is added to an aqueous solution composed of 0.1wt% PVA and other water-soluble polymer materials with the added amount of polyvinyl alcohol (PVA) 0% mass fraction to form 1×10 -8 mol / L indocyanine dye aqueous solution. The mixed solution was sonicated for 1h at room temperature and protected from light, and the ultrasonic frequency was 20KHz. Dry for 24 hours at room temperature and avoid light to obtain a fluorescent polymer composite.

Embodiment 2

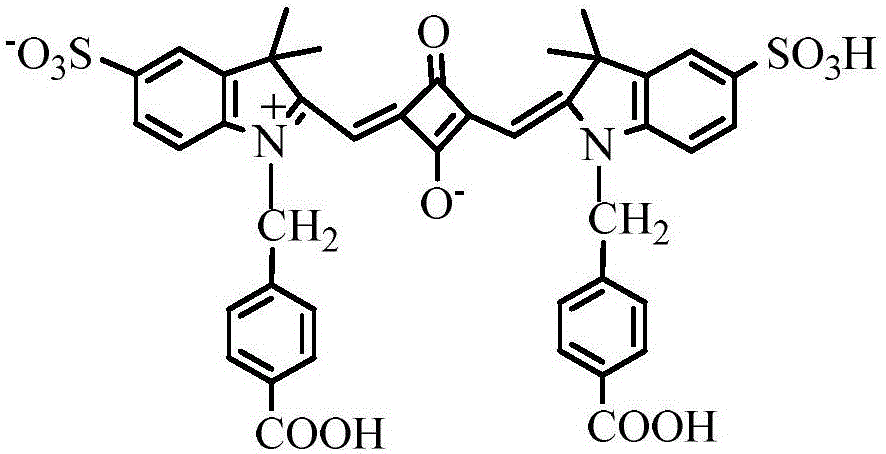

[0047] Dissolve 0.5 g of PVA in 9.5 g of deionized water, heat to 90° C., fully dissolve, and cool to room temperature to obtain 10 mL of a PVA aqueous solution with a mass fraction of 5 wt%. The indocyanine dye D2 (see the molecular structure figure 2 ) Is added to an aqueous solution composed of 5wt% PVA and polyvinyl pyrrolidone (PVP) with a mass fraction of 0.01% polyvinyl alcohol (PVA) to form 1×10 -6 mol / L indocyanine dye aqueous solution. The mixed solution was sonicated at room temperature and protected from light for 1 hour, and the ultrasonic frequency was 50KHz. Dry for 24 hours at room temperature and avoid light to obtain a fluorescent polymer composite.

Embodiment 3

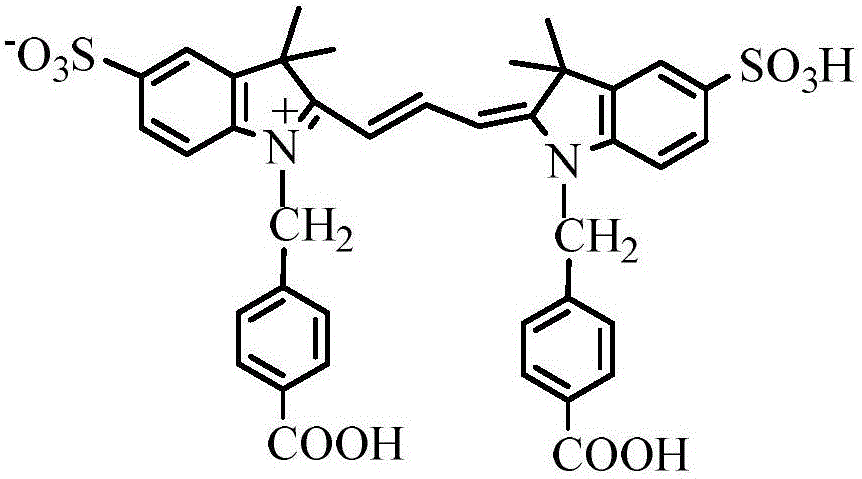

[0049] Dissolve 1.0 g of PVA in 9.0 g of deionized water, heat to 100° C., fully dissolve, and cool to room temperature to obtain 10 mL of a PVA aqueous solution with a mass fraction of 10 wt%. The indocyanine dye D3 (see the molecular structure image 3 ) Is added to an aqueous solution composed of 10wt% PVA and polyethylene glycol (PEG) with the added amount of polyvinyl alcohol (PVA) mass fraction 0.1% to form 1×10 -4 mol / L indocyanine dye aqueous solution. The mixed solution was sonicated at room temperature and protected from light for 2h, and the ultrasonic frequency was 100KHz. Dry for 24 hours at room temperature and avoid light to obtain a fluorescent polymer composite.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap