SERS substrate material and preparation method thereof

A substrate material and substrate technology, applied in the field of environmental science, can solve the problems of complex preparation process of film substrate, influence on test results, difficult process control, etc., and achieve the effect of cheap raw materials, simple process, and inhibition of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Ultrasonically disperse 2 g of boehmite in 10 g of deionized water, spin-coat the colloidal solution on the surface of a clean silicon substrate with a homogenizer at a speed of 700 rev / min, dry at room temperature for 30 min, and place it in a muffle furnace for 15 The heating rate of ℃ / min was heated to 500 ℃, and then cooled naturally after 2 hours of heat preservation to obtain a nano-alumina coated carrier with a uniform pore size distribution and a coating thickness of 1.2 μm. Prepare 5 ml of silver nitrate solution with a mass fraction of 0.1% and 5 ml of sodium citrate solution with a mass fraction of 0.05%, and mix the two solutions to obtain a reaction solution. Immerse the nano-alumina-coated carrier in the reaction solution, irradiate it under a 100w ultraviolet mercury lamp for 1h, take out the carrier, wash it with deionized water, and then dry it under high-purity nitrogen to obtain a nano-Ag surface-enhanced Raman spectrum base material.

Embodiment 2

[0027] Ultrasonically disperse 3g of boehmite in 10g of deionized water, spin-coat the colloid solution on the surface of a clean silicate glass substrate with a homogenizer at a speed of 700rev / min, dry it at room temperature for 30min, and place it in a muffle furnace Heating to 500°C at a heating rate of 5°C / min, keeping the temperature for 2 hours, and then cooling naturally to obtain a nano-alumina coated carrier with a uniform pore size distribution and a coating thickness of 1.5 μm. Configure 5 ml of silver nitrate solution with a mass fraction of 0.05% and 5 ml of sodium citrate solution with a mass fraction of 0.05%, and mix the two solutions to obtain a reaction solution. Immerse the nano-alumina-coated carrier in the reaction solution, irradiate it under a 100w ultraviolet mercury lamp for 2 hours, take out the carrier, rinse it with deionized water, and then dry it under high-purity nitrogen to obtain a surface-enhanced Raman spectrum of nano-Ag base material.

Embodiment 3

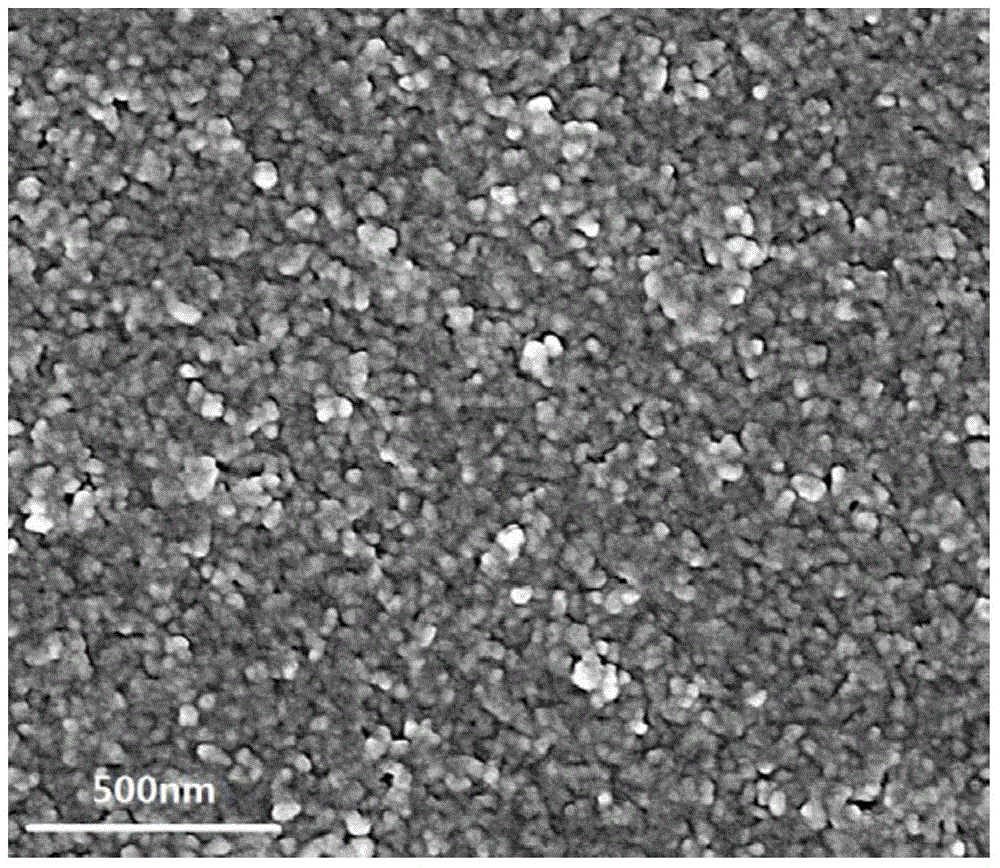

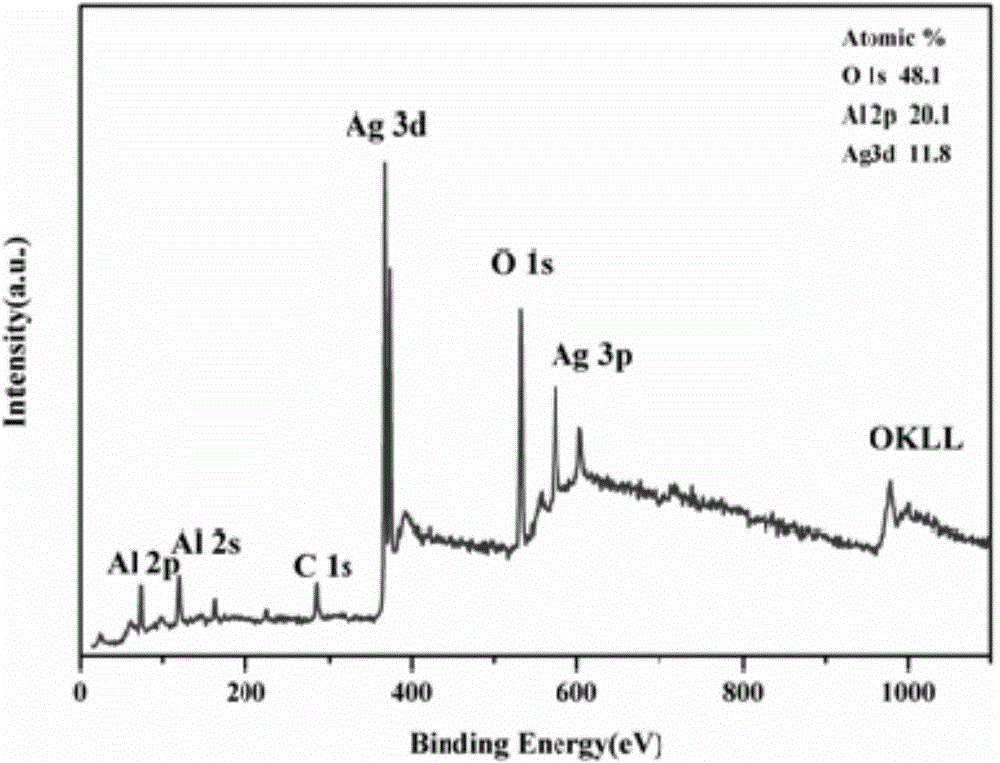

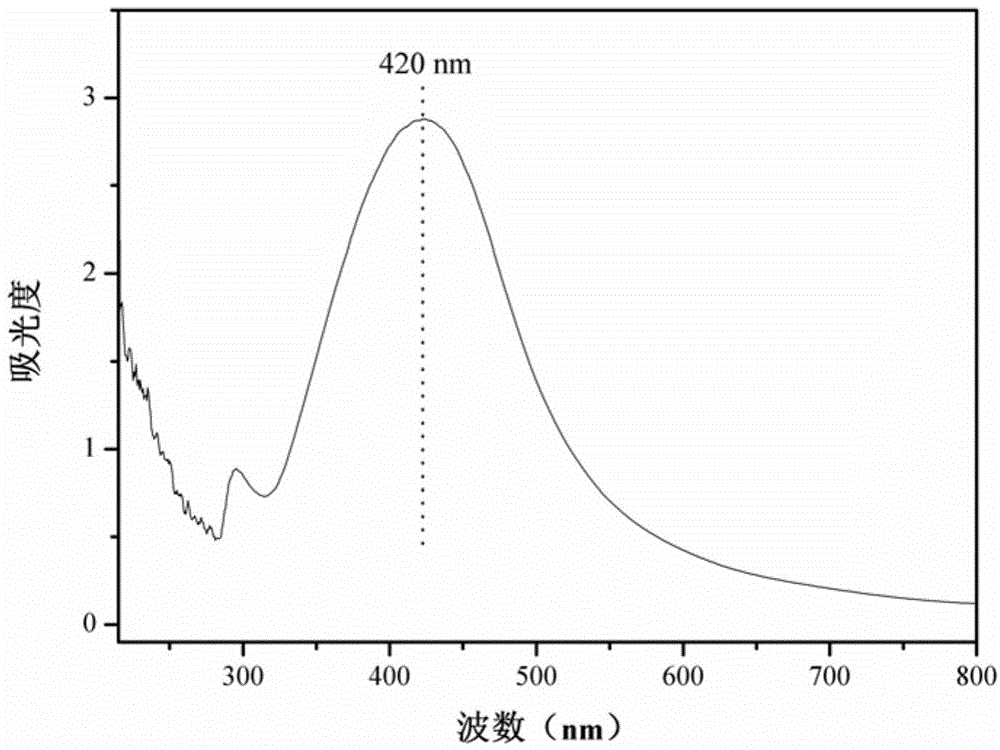

[0029] Ultrasonically disperse 2g of boehmite in 10g of deionized water, spin-coat the colloidal solution on the surface of a clean silicate glass substrate with a homogenizer at a speed of 500rev / min, dry it at room temperature for 30min, and place it in a muffle furnace Heating to 500°C at a heating rate of 5°C / min, keeping the temperature for 2 hours, and cooling naturally to obtain a nano-alumina coated carrier with a uniform pore size distribution and a coating thickness of 1.2 μm. Prepare 5 ml of silver nitrate solution with a mass fraction of 0.1% and 5 ml of sodium citrate solution with a mass fraction of 0.01%, and mix the two solutions to obtain a reaction solution. Immerse the nano-alumina-coated carrier in the reaction solution, irradiate it under a 100w ultraviolet mercury lamp for 0.5h, take out the carrier, wash it with deionized water, and then dry it under high-purity nitrogen to obtain a nano-Ag surface-enhanced Raman Spectral base material. figure 1 It is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com