Preparation and Application of a Supported Ruthenium Catalyst with Crystal Plane Effect

A ruthenium catalyst and catalyst technology, which are applied in the field of air pollution control, can solve problems such as preparation and performance research that have not yet been reported, and achieve the effects of low cost, broad application prospect and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

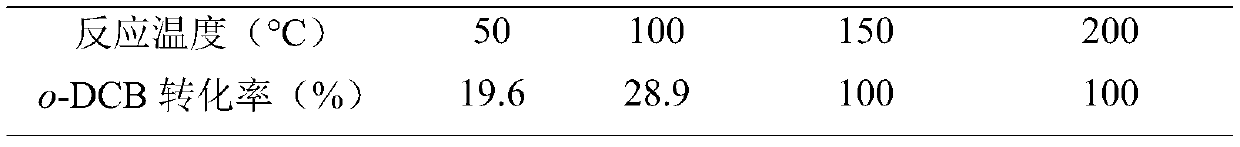

Embodiment 1

[0025] 1) Catalyst preparation

[0026] Add 20mL of butyl titanate to a reaction kettle containing 12mL of HF (24wt.%) solution, stir magnetically for 30min, and react at 200°C for 24h; after the reaction, cool the reaction kettle to room temperature, and wash it alternately with deionized water and absolute ethanol The reaction product was dried at 80°C for 12h; then calcined at 300°C for 2h in a nitrogen atmosphere to obtain TiO with preferentially exposed (001) crystal face 2 Carrier; Take 2.6235g RuCl 3 (1wt.%) solution to 20mL, dropwise added to 1g TiO 2 Suspended with 50 mL of deionized water and stirred at room temperature for 24 h, then dried at 60 °C to remove water, wherein the molar percentage of Ru / (Ru+Ti) was 1%; the recovered solid was added to 50 mL of NaBH 4 (0.4mol / L) ethanol solution and stirred until the bubbles stopped; after the reaction, the product was washed with 1mol / L ammonia solution and 60°C deionized water until the pH value of the filtrate reach...

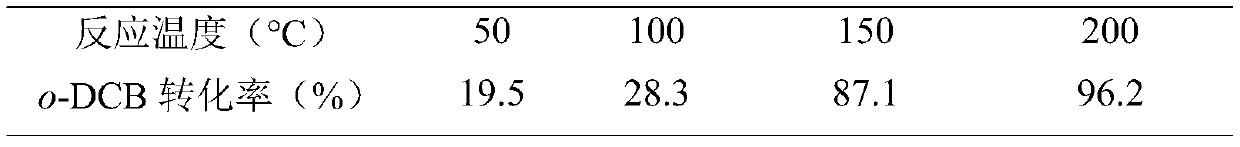

Embodiment 2

[0034] 1) Catalyst preparation

[0035] Add 20mL of butyl titanate to a reaction kettle containing 12mL of HF (24wt.%) solution, stir magnetically for 30min, and react at 200°C for 24h; after the reaction, cool the reaction kettle to room temperature, and wash it alternately with deionized water and absolute ethanol The reaction product was dried at 80°C for 12h; then calcined at 350°C under nitrogen atmosphere for 3h to obtain TiO with preferentially exposed (001) crystal face 2 Carrier; Take 2.3587g RuCl 3 (1wt.%) solution to 20mL, dropwise added to 1g TiO 2 Suspension with 50 mL of deionized water and stirred at room temperature for 24 h, then removed the water at 60 °C, wherein the molar percentage of Ru / (Ru+Ti) was 0.9%; the recovered solid was added to 45 mL of NaBH 4 (0.2mol / L) ethanol solution and stirred until the bubbles stopped; after the reaction, the product was washed with 1mol / L ammonia solution and 60°C deionized water until the pH value of the filtrate reach...

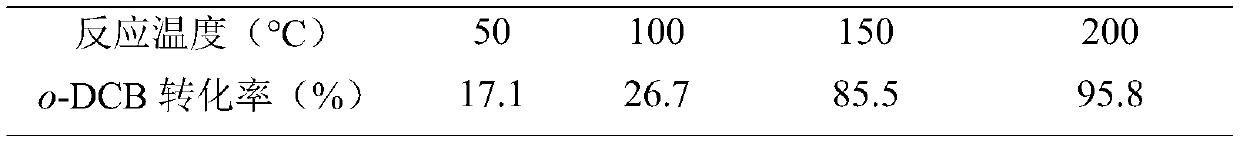

Embodiment 3

[0043] 1) Catalyst preparation

[0044] Add 20mL of butyl titanate to a reaction kettle containing 8mL HF (24wt.%) solution, stir magnetically for 30min, and react at 200°C for 24h; The reaction product was washed and dried at 80°C for 12h; then calcined for 2h at 450°C under a nitrogen atmosphere to obtain TiO with preferentially exposed (001) crystal face 2 Carrier; Take 2.6235g RuCl 3 (1wt.%) solution to 20mL, dropwise added to 1g TiO 2 Suspension with 50 mL of deionized water and stirred at room temperature for 24 h, then removed the water at 60 °C, wherein the molar percentage of Ru / (Ru+Ti) was 1%; the recovered solid was added to 40 mL of NaBH 4 (0.1mol / L) in the ethanol solution and stirred until the bubbles stopped; after the reaction, the product was washed with 1mol / L ammonia solution and 60°C deionized water until the pH value of the filtrate reached 7; finally dried at 80°C for 12h to obtain (001 ) face-dominated Ru / TiO 2 Catalyst, where Ru 0 / (Ru 0 +RuO x )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com