Preparation method of prussian blue analogue nano-material and use of prussian blue analogue in sodium-ion battery

A Prussian blue-like, sodium-ion battery technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of difficulty in forming high-proportion sodium intercalation compounds, inability to be used in production and life, poor cycle stability, etc. Simple method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Sample 1 # ~Sample 5 # preparation of

[0030] Add the aqueous solution containing potassium ferrocyanide into the buffer solution containing the metal element M, mix evenly, stir for a period of time, make it fully react, and obtain flocculent precipitates of different colors. After centrifuging the obtained precipitate, washing it with deionized water at least three times, and vacuum drying at 80° C., the Prussian blue-like nanomaterial is obtained.

[0031] For sample number, raw materials and preparation conditions, see surface 1 .

[0032] surface 1

[0033]

Embodiment 2

[0034] Example 2 Sample 6 # ~Sample 9 # preparation of

[0035] Add the aqueous solution containing potassium ferrocyanide into the buffer solution containing the metal element M, mix evenly, and stir for a period of time to allow it to fully react to obtain a flocculent precipitate. After the obtained precipitate was centrifuged, washed three times with deionized water, and vacuum-dried at 80° C., the Prussian blue-like nanomaterial was obtained.

[0036] For sample number, raw materials and preparation conditions, see surface 2 .

[0037] surface 2

[0038]

Embodiment 3

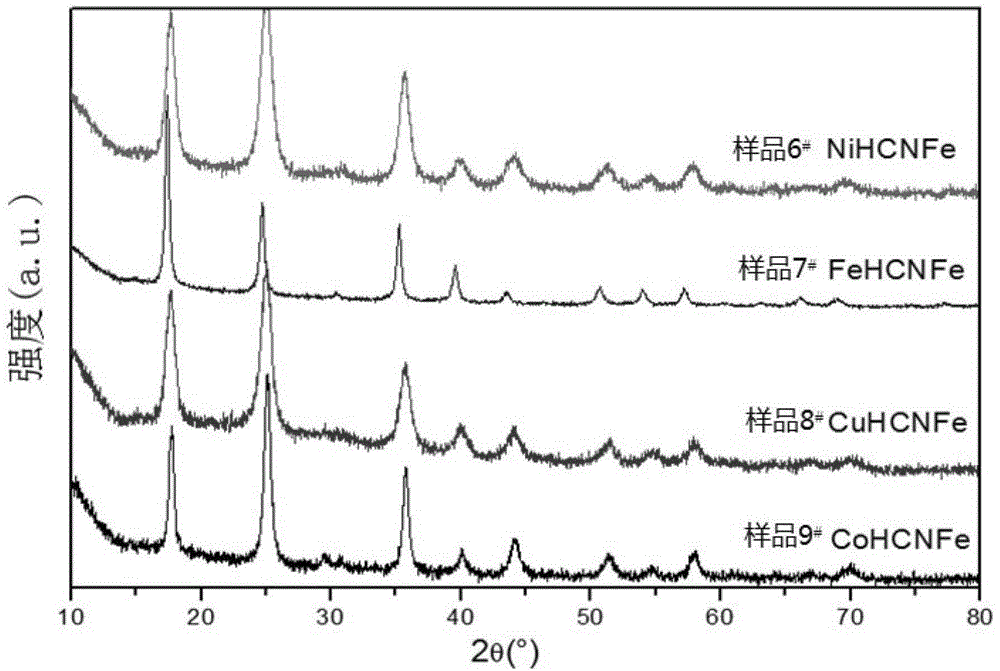

[0039] Example 3 Sample 1 # ~Sample 9 # XRD characterization

[0040] respectively for sample 1 # ~Sample 9 # Carry out XRD characterization, the result shows, sample 1 # ~Sample 9 # All are high-purity samples with Prussian blue crystal structure. Take sample 6 # ~9 # As a typical representative, its XRD spectrum Figure as shown 1 shown. sample 1 # ~Sample 5 # XRD spectrum picture with sample 6 # Close, that is, the peak position and shape are the same, and the relative peak intensity fluctuates in the range of ±10% according to the change of synthesis conditions, indicating that the synthesized product has the characteristics of Prussian blue crystal structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com