Gel emplastrum matrix and preparation method and application thereof

A plaster and gel technology, which is applied to the gel plaster base and the fields of preparation and use thereof, can solve the problems of unfavorable industrialized production, poor economic benefit, easy to fall off, etc., and achieves good skin followability, low cost, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Gel plaster matrix, it is made up of the component of following mass parts:

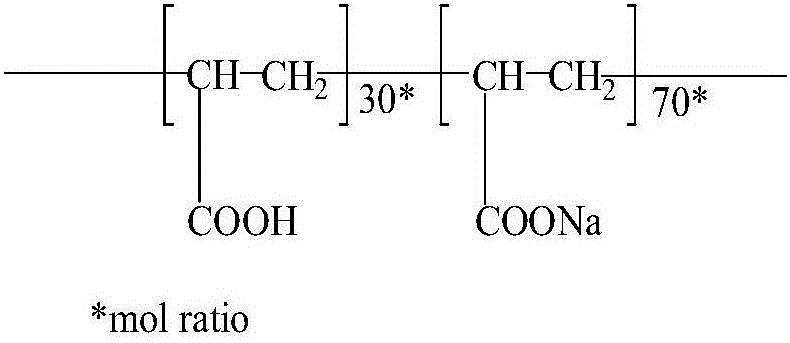

[0091] Partially neutralized sodium polyacrylate (NP-800): 5.2 parts, pullulan: 0.57 parts, aluminum glycolate: 0.29 parts, glycerin: 30 parts, disodium edetate: 0.20 parts, tartaric acid: 0.55 parts , Galantan: 0.49 parts, purified water: 68 parts.

[0092] According to the above ratio, take tartaric acid, add purified water, stir to dissolve, then add pullulan, continue to stir until it becomes a uniform solution, and obtain phase A; 1. Partially neutralize sodium polyacrylate and galadan, stir evenly, and obtain phase B;

[0093] The above-mentioned phase A is quickly added to the above-mentioned phase B, and stirred at a slow speed for 6-10 minutes to obtain a viscous colloid (gel plaster base); the above-mentioned viscous colloid is coated on the backing material. The paste content is 24g / 100cm 2 , cutting, packaging, that is.

Embodiment 2

[0095] Gel plaster matrix, it is made up of the component of following mass parts:

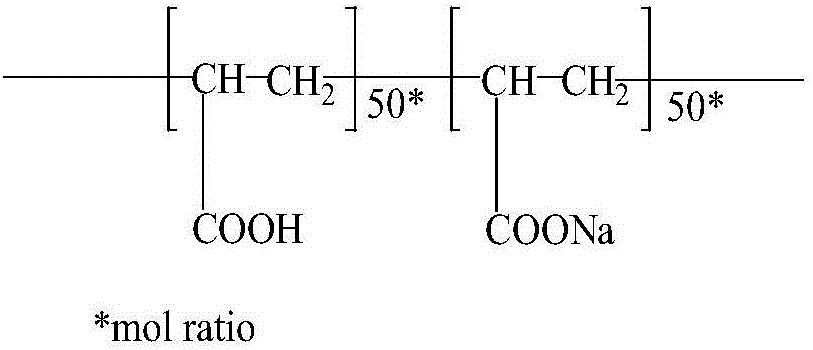

[0096] Partially neutralized sodium polyacrylate (NP-700): 4.9 parts, pullulan: 1.23 parts, aluminum glycerol: 0.14 parts, glycerin: 29 parts, disodium edetate: 0.09 parts, tartaric acid: 0.26 parts , Galantan: 0.4 parts, purified water: 68 parts.

[0097] According to the above ratio, take tartaric acid, add purified water, stir to dissolve, then add pullulan, continue to stir until it becomes a uniform solution, and obtain phase A; 1. Partially neutralize sodium polyacrylate and galadan, stir evenly, and obtain phase B;

[0098] The above-mentioned phase A is quickly added to the above-mentioned phase B, and stirred at a slow speed for 6-10 minutes to obtain a viscous colloid (gel plaster base); the above-mentioned viscous colloid is coated on the backing material. The paste content is 30g / 100cm 2 , cutting, packaging, that is.

Embodiment 3

[0100] Gel plaster matrix, it is made up of the component of following mass parts:

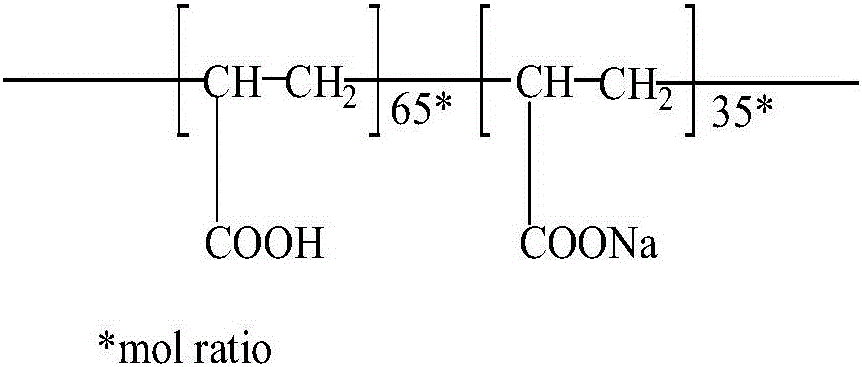

[0101] Partially neutralized sodium polyacrylate (NP-600): 5.24 parts, pullulan: 2.25 parts, aluminum glycerol: 0.28 parts, glycerin: 26 parts, disodium edetate: 0.19 parts, tartaric acid: 0.55 parts , Galantan: 0.42 parts, purified water: 70 parts.

[0102] According to the above ratio, take tartaric acid, add purified water, stir to dissolve, then add pullulan, continue to stir until it becomes a uniform solution, and obtain phase A; 1. Partially neutralize sodium polyacrylate and galadan, stir evenly, and obtain phase B;

[0103] The above-mentioned phase A is quickly added to the above-mentioned phase B, and stirred at a slow speed for 6-10 minutes to obtain a viscous colloid (gel plaster base); the above-mentioned viscous colloid is coated on the backing material. The paste content is 34g / 100cm 2 , cutting, packaging, that is.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com