Polyethylene glycol desulphurization composite film filled with active carbon and preparation method thereof

A polyethylene glycol and activated carbon technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as incomplete surface thickness and uneven membrane quality, and achieve low cost, simple preparation process, The effect of flux enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

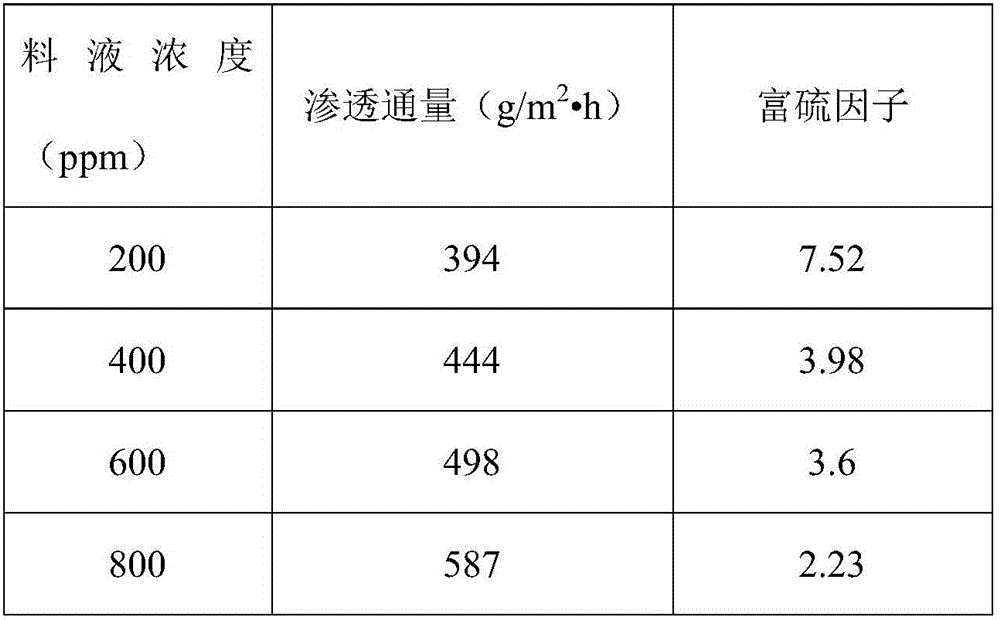

Embodiment 1

[0024] 1) Dry PVDF at 90°C for 6h, then stir and mix PVDF and triethyl phosphate at 70°C with a mass ratio of 3:17, filter and defoam for 4h, and stand at room temperature to obtain a clarified casting solution. Scrape the film on one side of the polyester non-woven fabric, use water as a gel bath, and solidify the PVDF base film supported by the non-woven fabric. After the solvent exchange is complete, soak the base film with 50% ethanol solution for 60 minutes. Dry naturally to obtain a PVDF porous bottom membrane with a thickness of 45 μm.

[0025] 2) 3g of polyethylene glycol with a viscosity of 615mPa·s is dissolved in the mixed solution of ethanol and water (the mass ratio of ethanol and water is 1:1), the mass fraction of polyethylene glycol in the mixed solution of ethanol and water After stirring evenly, add 0.15g (filling amount is 5%) activated carbon powder after passing through a 300 mesh sieve, stir and disperse evenly, add 0.48g maleic anhydride, 0.09g mass frac...

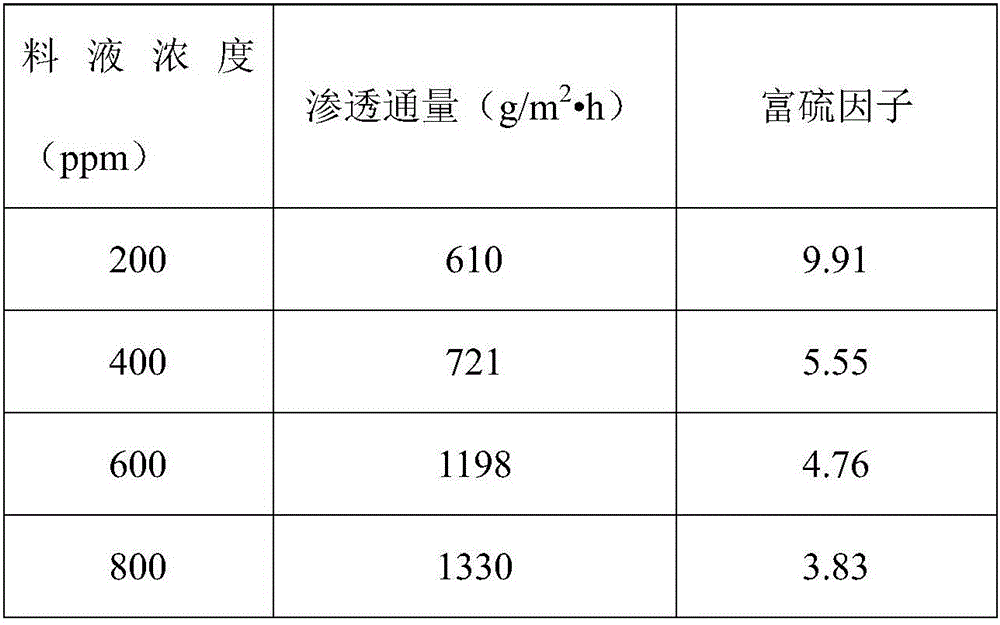

Embodiment 2

[0036] 1) Dry PVDF (polyvinylidene fluoride) at 90°C for 6h, then stir and mix PVDF and triethyl phosphate at 70°C with a mass ratio of 3:17, filter, defoam for 4h, and stand at room temperature to obtain Clarify the casting solution, scrape the film on one side of the polyester non-woven fabric, use water as a gel bath, and solidify the PVDF base film supported by the non-woven fabric. After the solvent exchange is complete, soak the base film in ethanol for 60 minutes, and the natural Dry to obtain a PVDF porous bottom membrane with a thickness of 45 μm.

[0037] 2) 3g of polyethylene glycol with a viscosity of 615mPa·s is dissolved in the mixed solution of ethanol and water (the mass ratio of ethanol and water is 1:1), the mass fraction of polyethylene glycol in the mixed solution of ethanol and water After stirring evenly, add 0.15g activated carbon powder (the filling amount is 5%) after passing through a 100 mesh sieve, stir and disperse evenly, then add 0.48g maleic anh...

Embodiment 3

[0039] The difference from Example 2 is that the mass of activated carbon powder is 0.3g (filling amount is 10%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com