A kind of intumescent composite flame retardant film and preparation method thereof

A composite flame retardant and intumescent technology, applied in the field of flame retardant films, can solve the problems of uneven dispersion of nano-silica and ammonium polyphosphate, poor interfacial compatibility, and decreased flame retardant efficiency, and achieve good strength and toughness, The effect of reducing bleed and improving flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

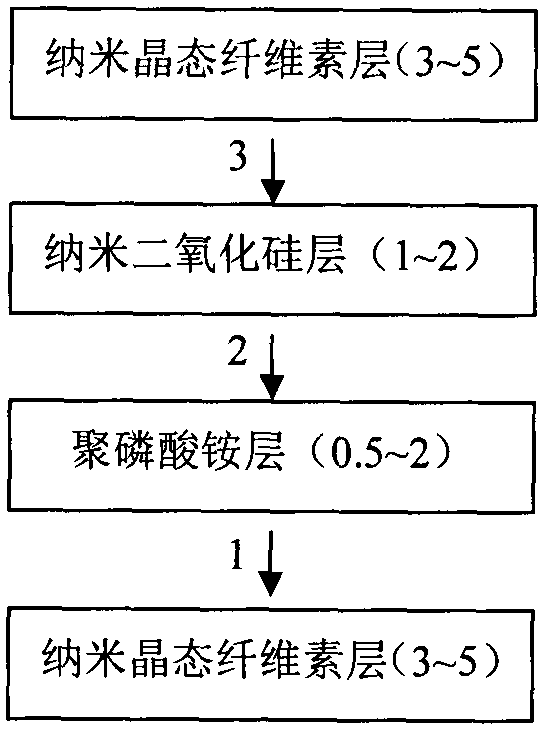

Method used

Image

Examples

Embodiment 1

[0016] (1) Take nanocrystalline cellulose and distilled water by mass ratio of 3: 100, and homogenize at 300 bar high pressure 8 times to obtain evenly dispersed nanocrystalline cellulose colloid;

[0017] (2) Weighing the nanocrystalline cellulose colloid in step (1) and adding it to a polytetrafluoroethylene tank, drying at 50-60°C for 0.5h to form a layer of nanocrystalline cellulose film;

[0018] (3) Take ammonium polyphosphate, NaCl, distilled water by mass ratio 13:3:100, fully stir, obtain ammonium polyphosphate electrolyte, join on the nanocrystalline cellulose film of step (2), at 50~60 ℃ Dry for 3 hours, repeat the operation 4 times to obtain a nanocrystalline cellulose-ammonium polyphosphate film, and make the mass ratio of nanocrystalline cellulose in the formed film: ammonium polyphosphate to be 3:0.5;

[0019] (4) Weigh tetraethyl orthosilicate, ethanol, HCl and distilled water according to the mass ratio of 60:20:0.25:100, and mix ethyl orthosilicate, ethanol, ...

Embodiment 2

[0024] (1) Take nanocrystalline cellulose and distilled water by mass ratio of 4: 100, and homogenize under high pressure at 400 bar for 6 times to obtain evenly dispersed nanocrystalline cellulose colloid;

[0025] (2) Weighing the nanocrystalline cellulose colloid in step (1) and adding it to a polytetrafluoroethylene tank, drying at 50-60° C. for 1 hour to form a layer of nanocrystalline cellulose film;

[0026] (3) Take ammonium polyphosphate, NaCl, distilled water by mass ratio 10:3:100, fully stir, obtain ammonium polyphosphate electrolyte, join on the nanocrystalline cellulose film of step (2), at 50~60 ℃ Drying for 3 hours, repeating the operation 6 times to obtain a nanocrystalline cellulose-ammonium polyphosphate film, and making the mass ratio of nanocrystalline cellulose in the formed film: ammonium polyphosphate to be 4:1;

[0027] (4) Weigh tetraethyl orthosilicate, ethanol, HCl and distilled water according to the mass ratio of 70:20:0.25:100, and mix ethyl orth...

Embodiment 3

[0032] (1) Take nanocrystalline cellulose and distilled water by mass ratio 5: 100, homogenize at 500 bar high pressure 8 times, obtain evenly dispersed nanocrystalline cellulose colloid;

[0033] (2) Weighing the nanocrystalline cellulose colloid in step (1) and adding it to a polytetrafluoroethylene tank, drying at 50-60° C. for 1 hour to form a layer of nanocrystalline cellulose film;

[0034] (3) Take ammonium polyphosphate, NaCl, distilled water by mass ratio 15:3:100, fully stir, obtain ammonium polyphosphate electrolyte, join on the nanocrystalline cellulose film of step (2), at 50~60 ℃ Drying for 5h, repeating the operation 3 times to obtain a nanocrystalline cellulose-ammonium polyphosphate film, and making the mass ratio of nanocrystalline cellulose in the formed film: ammonium polyphosphate to be 5:2;

[0035] (4) Weigh tetraethyl orthosilicate, ethanol, HCl and distilled water according to the mass ratio of 80:20:0.25:100, and place orthosilicate ethyl, ethanol, HC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com