Integrated device for suspension flash preparation of high activity light calcined magnesia

A technology of light-burned magnesia and a complete set of equipment, which is applied in the direction of lime production, etc., can solve the problems of slow decomposition reaction, incomplete internal roasting, low degree of automation, etc., and achieve high product activity, high waste heat utilization rate, and good working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

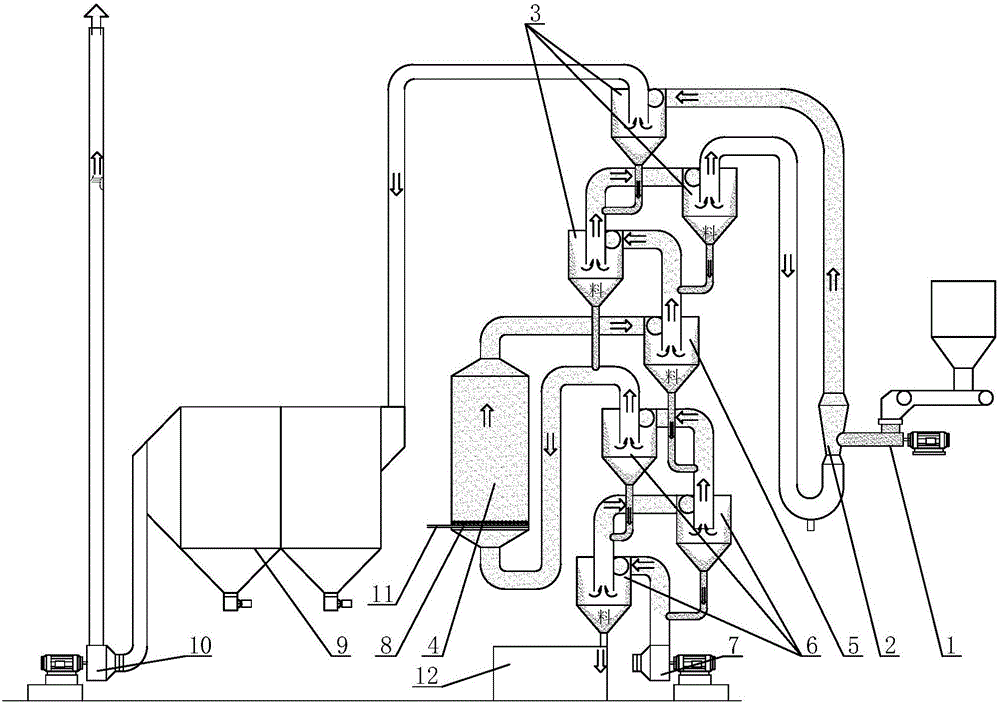

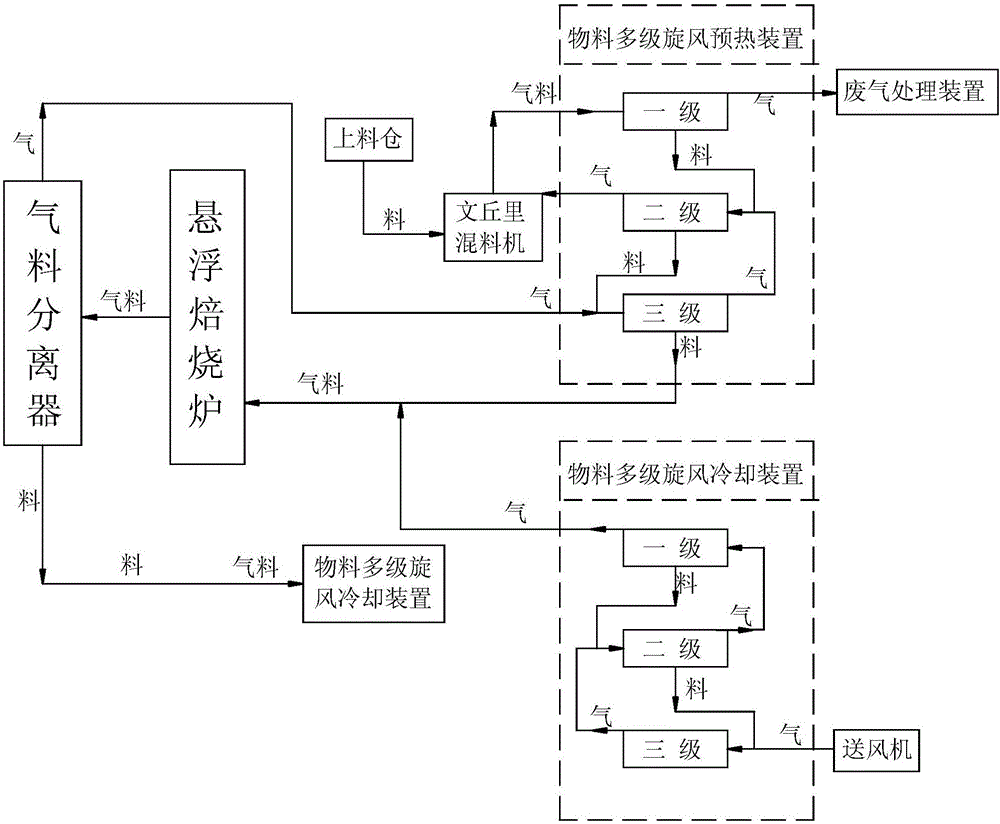

[0016] Integrated advanced technology is one of the key technologies for the production of high-efficiency light-burned magnesia. The complete set of equipment for preparing high-activity light-burned magnesia by suspension flash includes feeder 1, Venturi mixer 2, and material multi-stage cyclone preheating device 3 , a suspension roaster (4), a gas-material separation device 5, a material multi-stage cyclone cooling device 6, a blower fan 7, a fuel nozzle 8, a waste gas treatment device 9, and an induced draft fan 10;

[0017] The gas-material separation device includes a circular separation cylinder. The gas material inlet is arranged on the side wall of the separation cylinder. Collecting hopper, the bottom of the collecting hopper is the discharge port, the center of the separation cylinder is equipped with an air collecting pipe, and the upper end of the air collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com