Surface-modified ion-imprinted polymer microspheres and preparation method thereof

An ion imprinting and surface modification technology, applied in alkali metal compounds, chemical instruments and methods, other chemical processes, etc., can solve problems such as poor adsorption effect, achieve good adsorption performance, improve hydrophilic performance, and excellent anti-interference ability. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

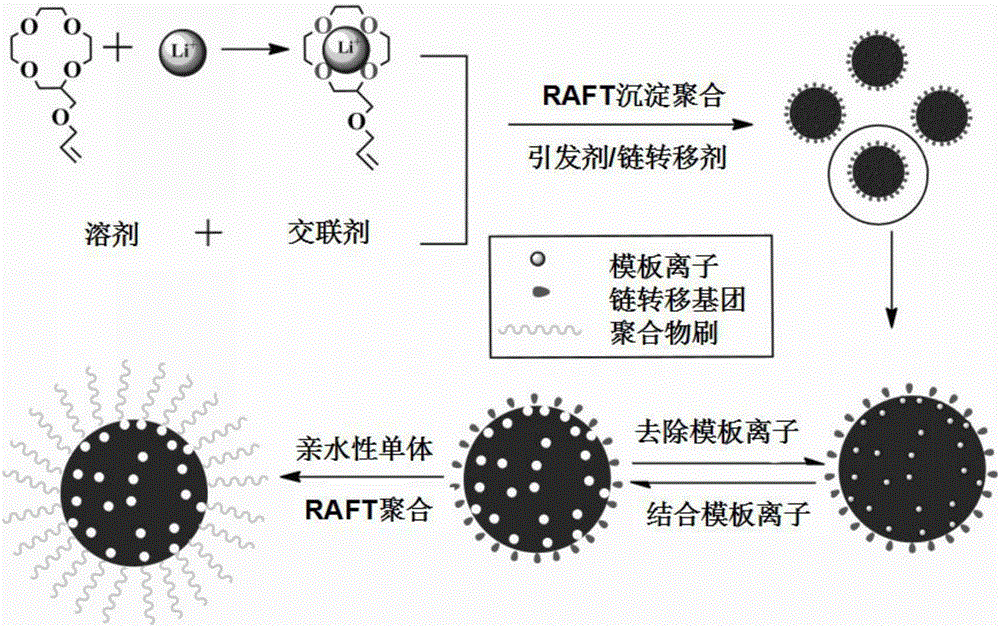

[0041] The invention provides a method for preparing surface-modified ion-imprinted polymer microspheres, comprising the following steps:

[0042] Carrying out the grafting reaction of the hydrophilic monomer, the first initiator, the first chain transfer agent and the ion-imprinted polymer microsphere under the condition of the first organic solvent to obtain the surface-modified ion-imprinted polymer microsphere;

[0043] The temperature of the grafting reaction is 60-90°C;

[0044] The time of the grafting reaction is 8-48 hours.

[0045] In the invention, the hydrophilic monomer, the first initiator, the first chain transfer agent and the ion-imprinted polymer microsphere are subjected to grafting reaction under the condition of the first organic solvent to obtain the surface-modified ion-imprinted polymer microsphere. In the present invention, the hydrophilic monomer is preferably 2-hydroxyethyl methacrylate, methacrylic acid, N-isopropylacrylamide, methyl methacrylate a...

Embodiment 1

[0077] 0.09g of LiCl·H 2O, 0.369g allyloxy-12-crown-4, 1.485g ethylene glycol dimethacrylate (EGDMA), 0.064g AIBN and 0.179g cumyl thiobenzoate were dissolved in a volume concentration of 80 % methanol aqueous solution, blow nitrogen for 30min, and react at 65°C water bath temperature for 24h.

[0078] After the reaction, the reaction product was filtered, rinsed three times with 80% methanol aqueous solution, and washed three times with 1 mol / L nitric acid to elute the template ions from the polymer microspheres. Vacuum drying at 40° C. and 0.08 MPa for 24 hours gave pink ion-imprinted polymer microspheres.

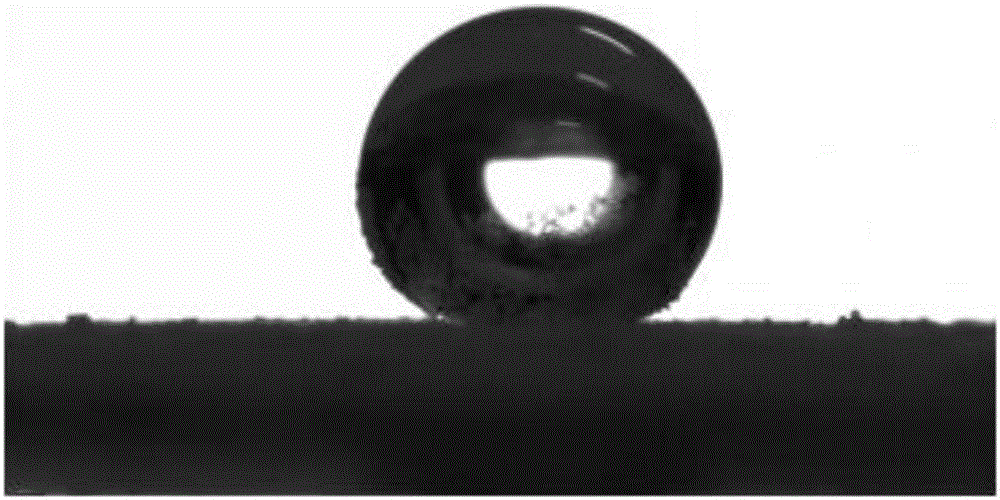

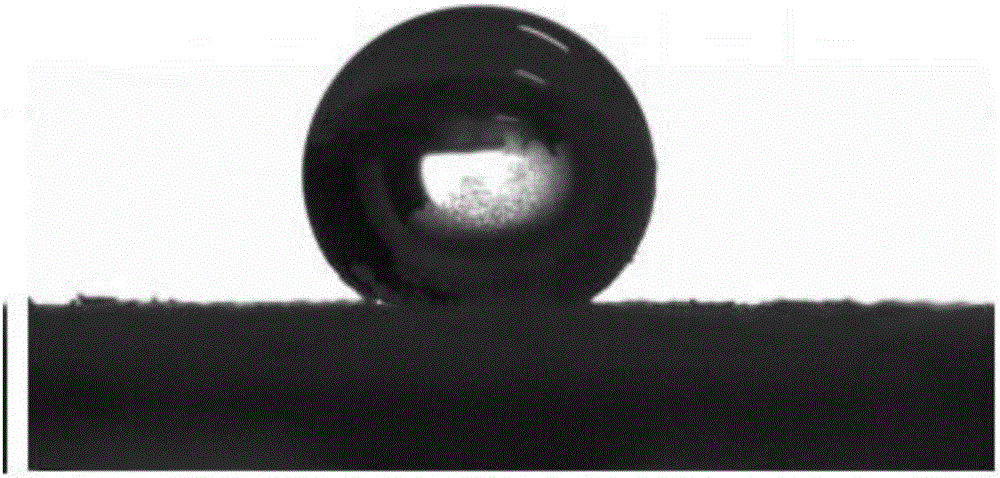

[0079] 500 mg of ion-imprinted polymer microspheres obtained above, 5.85 g of 2-hydroxyethyl methacrylate, 25 mg of cumyl thiobenzoate, and 6 mg of azobisisobutyronitrile were sequentially added into 50 mL of methanol. React at 65°C and 0.08MPa for 24h. After the reaction system was centrifuged, the obtained solid product was thoroughly washed with methanol until no w...

Embodiment 2

[0090] 0.855g of CdCl 2 2.5H 2 O, 0.260g of 3-allyl rhodanine, 1.573g of trimethylolpropyl trimethacrylate (TRIM), 0.064g of AIBN and 0.183g of cumylthiobenzoate are dissolved in a volumetric concentration of 80 % methanol aqueous solution, blow nitrogen for 30min, and react for 48h at the water bath temperature of 90°C.

[0091] After the reaction, the reaction product was filtered, rinsed three times with 80% aqueous methanol and three times with 1 mol / L hydrochloric acid to elute the template ions from the polymer microspheres. Vacuum drying at 40° C. and 0.06 MPa for 24 hours gave pink ion-imprinted polymer microspheres.

[0092] 500 mg of the ion-imprinted polymer microspheres obtained above, 2.93 g of methacrylic acid, 25 mg of cumyl thiobenzoate, and 6 mg of azobisisobutyronitrile were sequentially added into 50 mL of methanol. React at 85°C and 0.06MPa for 24h. After the reaction system was centrifuged, the obtained solid product was thoroughly washed with methanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com