High-hardness rubber, and preparation method and application thereof

A high-hardness, rubber technology, applied in the field of rubber products, can solve the problems of rubber ring swelling, large geometric size tolerance, poor insulation performance, etc., to achieve good wear resistance and aging resistance, good reinforcement and process performance, Good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

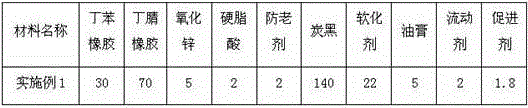

Embodiment 1

[0043] High-hardness rubber, which is mainly prepared from the raw material components shown in the following Table 1 in parts by mass. The preparation method specifically includes the following steps:

[0044] S1: Put the styrene-butadiene rubber into the open mill and open it from block to sheet, adjust the roller distance to 0.8-1.3 mm for thin pass, make triangular bags 5-6 times, and set aside;

[0045] S2: Put the nitrile rubber into the open mill and open it from block to sheet, adjust the roller distance to 0.8-1.3 mm for thin pass, make triangular bags 5-6 times, and set aside;

[0046] S3: put the sheet rubber prepared in steps S1 and S2 into the open mill together, adjust the roller distance to 0.8-1.3 mm for thinning, make triangular bags 5-6 times, and blend evenly to obtain a total Mixed rubber;

[0047] S4: After the blended raw rubber prepared in step S3 is parked for 2-3 hours, it is put into a kneader, and zinc oxide, stearic acid, anti-aging agent, ointment...

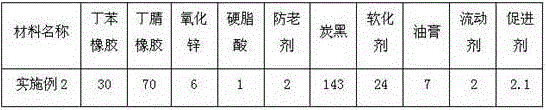

Embodiment 2

[0056] Table 2 is the formula table of embodiment 2.

[0057]

[0058] Table 3 shows the performance comparison between the high-hardness rubber prepared in Example 1 and Example 2 and the high-hardness rubber used in the high-hardness V-shaped rubber sealing ring in the prior art.

[0059]

[0060] As can be seen from Table 3, by the raw material ratio of the high hardness rubber in the embodiment and the preparation method of the high hardness rubber, the overall performance of the product is effectively improved, and the high hardness rubber formed by the preparation has oil resistance, wear resistance and The aging resistance is better than that of the comparative example, and it can be used to make V-shaped rubber sealing rings, which can solve the technical problem that the existing high-hardness V-shaped rubber sealing rings cannot meet the requirements of oil resistance, wear resistance and aging resistance at the same time, making V-shaped rubber sealing rings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com