Silicone rubber with excellent tracking resistance and high heat conductivity

A technology of tracking resistance and high thermal conductivity, which is applied in the field of electrical insulating polymer materials, can solve problems such as threats to the safe operation of the power grid, poor thermal conductivity, and temperature rise, and achieve improved tracking resistance, obvious thermal conductivity, and The effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

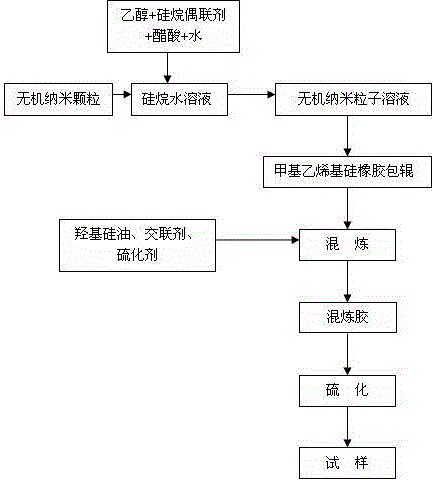

[0046] (1) Take nano-ATH with a mass fraction of 100% (relative to the silicone rubber matrix), and perform surface treatment on the nanoparticles. The steps are: take 150% ethanol and pour it into a beaker, and then add 5% The silane coupling agent, the mass fraction is 0.3% acetic acid and the mass fraction is 1.25% water, the pH value of the solution is adjusted to about 5, and the silane coupling agent is fully hydrolyzed with an electromagnetic stirrer for 40 minutes to obtain the silane aqueous solution; the ATH particles Add it into the silane aqueous solution, and stir with an electromagnetic stirrer for 40 minutes to obtain an inorganic nanoparticle solution.

[0047] (2) Mixing the silicone rubber matrix with the inorganic nanoparticle solution: place the methyl vinyl silicone rubber matrix on the rubber mixer, and gradually add the inorganic nanoparticle solution in step 1) after wrapping the roll, and mix evenly to obtain the silicone rubber and A blend of emulsion...

Embodiment 2

[0051] The doped nanoparticles were replaced by ATH with a mass fraction of 100% in Example 1 to BN with a mass fraction of 100%, and the amount of other reagents remained unchanged; other steps were the same as in Example 1.

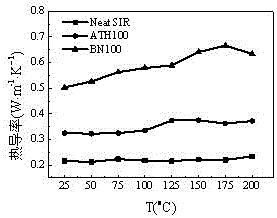

[0052] Figure 2(a)Under the condition that the sample preparation environment and other reagent dosage ratios are exactly the same, the doped particles are respectively 100% ATH and 100% BN (Example 1-2) of the thermal conductivity versus temperature curve comparison chart, it is found that Both ATH and BN can improve the thermal conductivity of silicone rubber, and the thermal conductivity of BN filled silicone rubber increases more than ATH filled, up to 0.6Wm -1 k -1 .

Embodiment 3

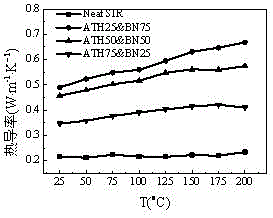

[0054] It is the ATH of 100% to replace the ATH that is 25% and the BN that massfraction is 75% by the massfraction in embodiment 1 by the nanoparticle of doping, the consumption of other reagents is constant; Other steps are with embodiment 1 same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com