Method for preparing light-color disproportionated rosin by using organic ceramsite decolorising agent

A technology of decolorizing agent and ceramsite, which is applied in the field of deep processing of rosin, can solve the problems of insignificant effect of adsorption decolorization method, unsatisfactory decolorization effect of saponification method, large amount of solvent in crystallization extraction method, etc., and achieves high yield, easy filtration and removal, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

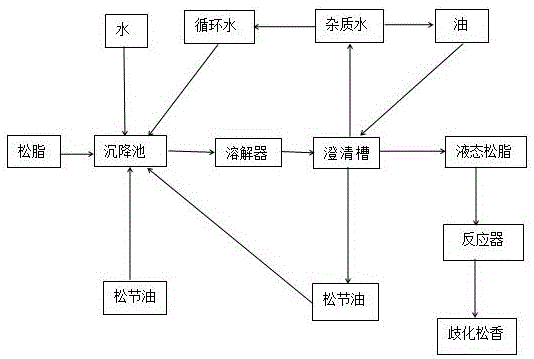

[0034] 1) Put 2 tons of turpentine into the settling tank, send the rosin to the dissolver with a screw conveyor for dissolution, add 600kg of turpentine and 600kg of water when dissolving, pass in steam when dissolving, and control the temperature at 90°C, evaporated during the dissolving process The turpentine and water vapor are recovered by the condenser on the upper part of the dissolver; the dissolved fat liquid passes through the filter device in the dissolver to remove coarse impurities and then enters the clarification tank;

[0035] 2) Nitrogen gas is introduced, and the dissolved fat liquid is allowed to stand in the clarification tank for 6 hours, so that the fat liquid and water are separated by themselves, and the lower layer of water is discharged, and the upper layer of fat liquid is the standing fat liquid. As the raw material for disproportionation reaction, it is sent to the reactor; the water and turpentine steam from the clarification tank enters the conden...

Embodiment 2

[0041] 1) Put 4 tons of turpentine into the settling tank, send the rosin to the dissolver with a screw conveyor for dissolution, add 1200kg of turpentine and 1200kg of water when dissolving, and pass through the opening steam when dissolving, the temperature is controlled at about 95°C, and evaporates during the dissolution process The turpentine and water vapor coming out are recovered by the condenser on the upper part of the dissolver; the dissolved fat liquid passes through the filter device in the dissolver to remove coarse impurities and then enters the clarification tank;

[0042] 2) Introduce nitrogen gas, and let the dissolved fat liquid stand in the clarification tank for 8 hours, so that the fat liquid and water will be separated by themselves, and the lower layer of water will be discharged, and the upper layer of fat liquid will be the standing fat liquid. As the raw material for disproportionation reaction, it is sent to the reactor; the water and turpentine stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com