Detersive waterproof polishing car-washing solution

A technology of car washing liquid and antifreeze, which is applied in the direction of polishing composition, detergent compounding agent, detergent composition, etc., can solve the problems of wasting solvent, polluting the environment, and taking a long time, and achieves the effect of not being yellow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

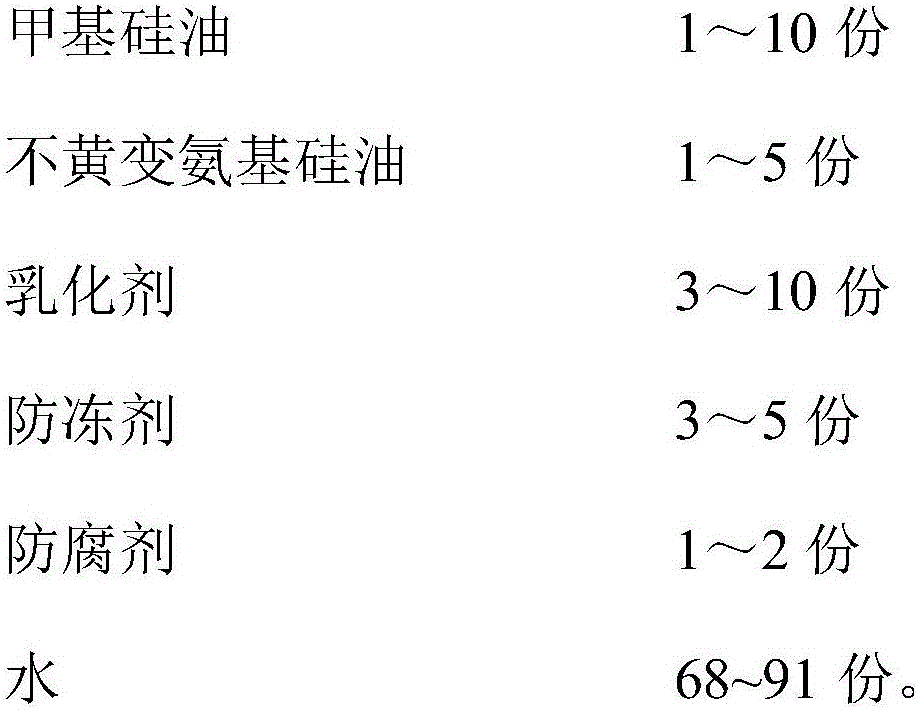

[0022] The decontamination waterproof glazing car wash liquid of the present embodiment, each component formula is as follows:

[0023]

[0024]

[0025] In a 500ml plastic cup, stir the silicone oil and emulsifier evenly to obtain the oil phase material; add acetic acid and propylene glycol to the deionized water to obtain the water phase material; in the high-speed homogenizer, turn on the homogenizer, and divide the water phase material Add it into the oil phase material for emulsification. The speed of the homogenizer is 2000-4000rpm. After homogenizing for 30 minutes, the decontamination, waterproof and glazing car wash liquid is obtained.

[0026] The average particle diameter of the emulsion measured is 1 micron, and then the mechanical stability test, thermal stability test, low temperature stability test and dilution test with tap water are all qualified.

Embodiment 2

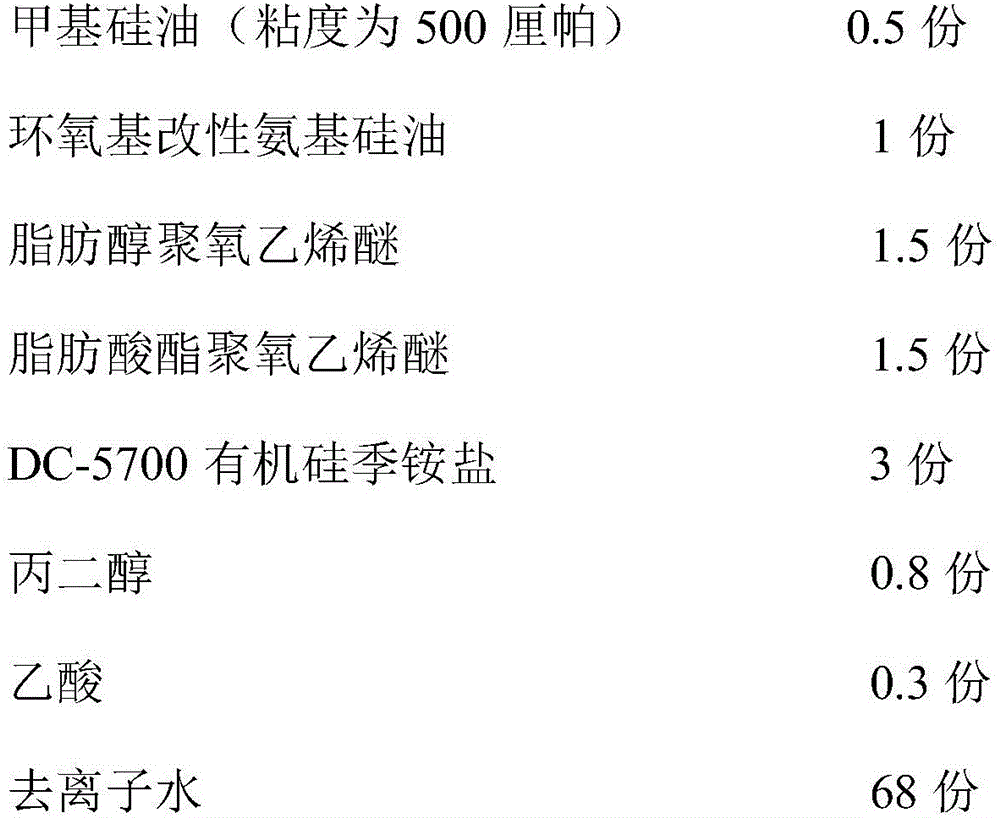

[0028] The decontamination waterproof glazing car wash liquid of the present embodiment, each component formula is as follows:

[0029]

[0030]

[0031] In a 500ml plastic cup, stir the silicone oil and emulsifier evenly to obtain the oil phase material; add acetic acid and propylene glycol to the deionized water to obtain the water phase material; in the high-speed homogenizer, turn on the homogenizer, and divide the water phase material Add it into the oil phase material for emulsification. The speed of the homogenizer is 2000-4000rpm. After homogenizing for 30 minutes, the decontamination, waterproof and glazing car wash liquid is obtained.

[0032] The average particle diameter of the emulsion measured is 1 micron, and then the mechanical stability test, thermal stability test, low temperature stability test and dilution test with tap water are all qualified.

[0033] Dilute 200 grams of the above car wash solution with water 10 times to get 2 liters of car wash wor...

Embodiment 3

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com