Biological treatment agent capable of efficiently degrading kitchen waste and preparation method of biological treatment agent

A technology for food waste and biological treatment, applied in the direction of biochemical equipment and methods, methods based on microorganisms, microorganisms, etc., can solve the problems of poor effect and low efficiency, achieve good treatment effect, simple preparation method, and stable treatment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Preparation of biological treatment agent:

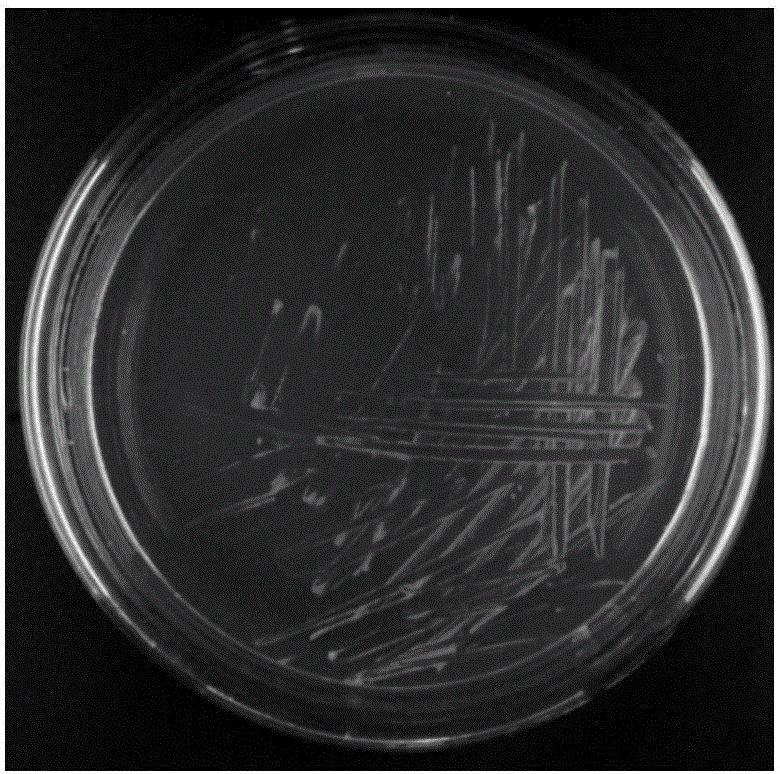

[0099] (1) Brevibacterium aureus, Bacillus licheniformis and Bacillus subtilis were inoculated on LB solid medium, Candida glabrata and Pediococcus lactis were inoculated on MRS solid medium. In the bottle, shake culture at 30°C and 130r / min for 24h to form seed liquid.

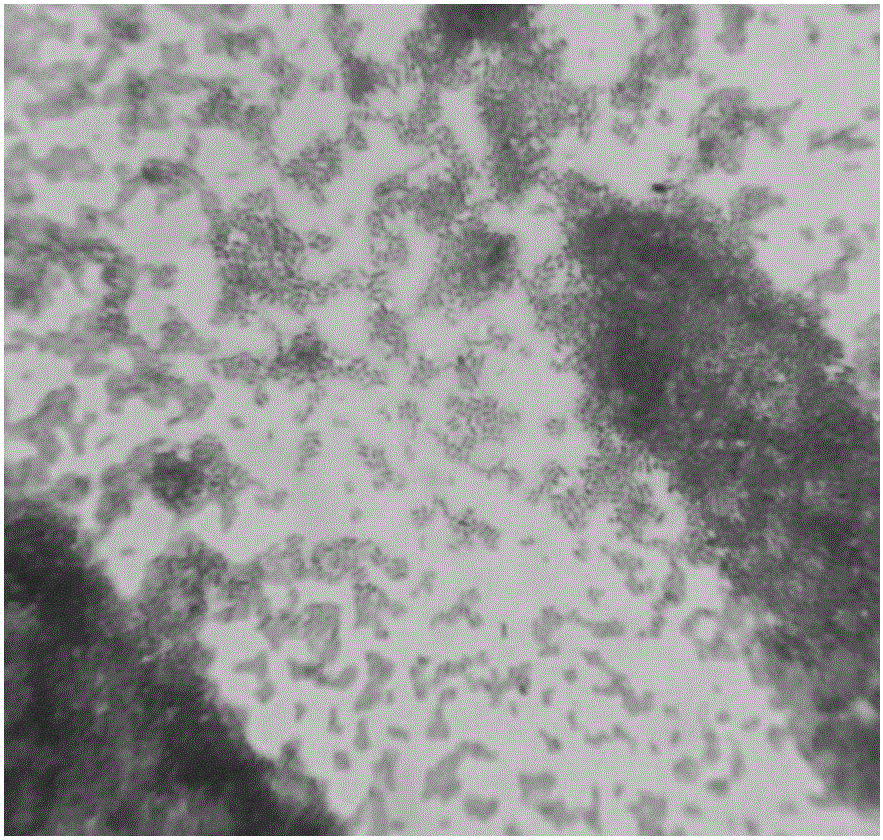

[0100] Then inoculate the seed liquid into the culture material in the fermenter at a volume ratio of 1:400 for fermentation and production. The basic working parameters of the fermenter are: temperature: 30-35°C, stirring speed: 130r / min, pH=6.2 ~7.2, dissolved oxygen: 30%, tank pressure: 0.04MPa. Stop the fermentation after 24 hours, then centrifuge at 6000r / min for 10 minutes, take the precipitate and dilute it with sterile water to make a bacterial agent. The concentration of viable bacteria in the bacteria agent was detected to be 1×10 9 ~1×10 10 CFU / mL (wherein the fermentation pH of Brevibacterium aureus, Bacillus licheniformis and Bacillus subtil...

example 1

[0104] Biological bacteria agent in example 1 is to the weight loss efficiency test after kitchen waste is processed:

[0105] (1) The composition of kitchen waste: the food left in the canteen, remove the large and hard parts such as plastic or bones;

[0106] (2) Apply the biological treatment agent prepared by the above method to the treatment of kitchen waste. Preheat and run for 6 hours while ventilating and stirring. Add 10kg of food waste to be treated into the processor after pre-operation, mix with biological treatment agent for aerobic fermentation, and ventilate and stir at the same time. The amount of biological treatment agent added is 6.5kg, the aerobic fermentation temperature is 45-55°C, the ventilation is continuous, the motor continues to rotate forward for 5 minutes, stop for 60 seconds, reverse for 5 minutes, stop for 60 seconds, and execute in a cycle. The test lasted for 5 days, adding 10kg every day, feeding once every 24 hours;

[0107] (3) Determina...

Embodiment 2

[0113] In addition to 15 parts of Brevibacterium aureum (Brevibacterium aureum), 25 parts of Bacillus licheniformis (Bacillus licheniformis), 25 parts of Bacillus subtilis (Bacillus subtilis), Candida glabrata ) 20 parts and 15 parts of Pediococcus acidilactici (Pediococcus acidilactici) carry out the liquid inoculant mixing; In step (2), sawdust, bran powder and rice husk are 5:2:3 according to mass ratio; Step (3) according to microbial inoculum and The mass ratio of the carrier is 2:15, except stirring and mixing in the processor, other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com