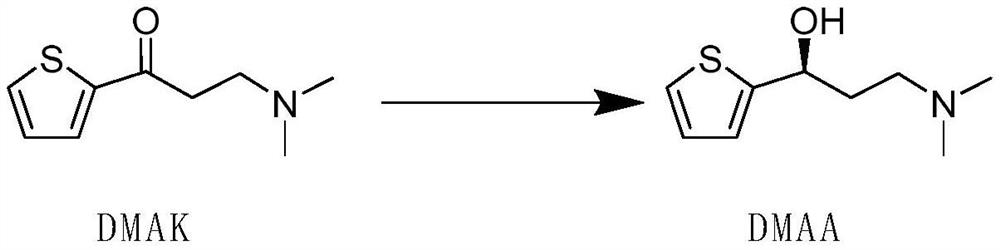

Engineered ketoreductase polypeptides and methods for preparing (s)-3-(dimethylamino)-1-(thiophen-2-yl)-1-propanol

A dimethylamine-based, reductase technology, applied in the directions of oxidoreductase, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of high enzyme amount, long reaction time, low substrate concentration, etc. The effect of low dosage, short reaction time and high substrate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

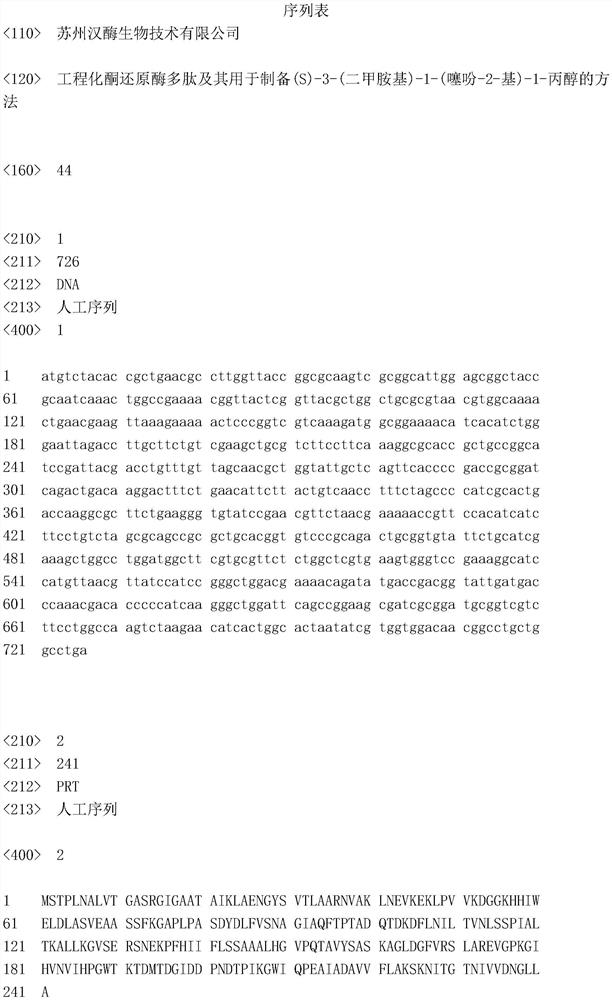

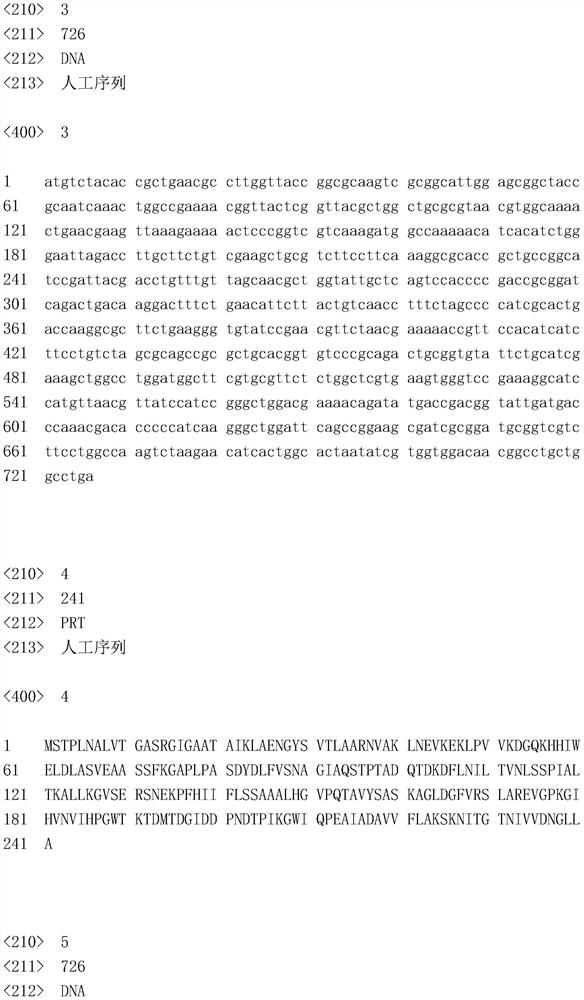

[0015] Embodiment 1 (preparation of ketoreductase)

[0016] A ketoreductase catalyst was prepared by a conventional method: 1, 3, 5, 7, 9, 11, 13, 15, 17, 19, 21, 23, 25, 27, 29, 31, 33, 35, The gene fragments of 37, 39, 41, and 43 were synthesized by Suzhou Jinweizhi Biotechnology Co., Ltd., ligated with pET30a (Novagen) plasmid digestion products, and transformed into competent E.coli BL21 (DE3) strains, and positive clones were obtained by screening , inoculated into liquid LB medium containing resistance, cultivated at 37°C until OD600 to 0.8, added inducer IPTG, continued to cultivate for 16 hours, collected the precipitate by centrifugation, added phosphate buffer to suspend, and ultrasonicated for 10 minutes in an ice-water bath , centrifuge to get the supernatant, and freeze to obtain ketoreductase enzyme powder.

Embodiment 2

[0017] Embodiment 2 (screening of ketoreductase)

[0018] Expressed in E. coli by the sequences 1, 3, 5, 7, 9, 11, 13, 15, 17, 19, 21, 23, 25, 27, 29, 31, 33, 35, 37, 39, 41, 43 The obtained ketoreductase 2mg, GDH (purchased from Suzhou Hanzyme Biotechnology Co., Ltd., brand EW002) 2mg, NADP 1mg, substrate DMAK 50mg, glucose 50mg were added to a 5mL reactor containing 2mL 0.05M triethanolamine buffer , stirred at 1000rpm at 30°C, sampled for HPLC detection after 1h, the conversion rate and ee of sequence 43 were both >99%, so sequence 43 was used as the object of further research.

Embodiment 3

[0019] Embodiment 3 (enzyme catalyzed reaction)

[0020] Add 2.0g of substrate DMAK, 3g of glucose, and 9mL of 0.05M pH 7.0 triethanolamine buffer solution to a 50mL three-necked reaction flask in sequence, adjust the temperature to 30°C, stir at 900r / min, and use 15% Na 2 CO 3 The solution maintains the pH of the reaction system to 7.0, and 6 mg of ketoreductase (obtained by expression of sequence 43 in Escherichia coli), 6 mg of glucose dehydrogenase (purchased from Suzhou Hanzyme Biotechnology Co., Ltd., brand EW002) and 0.5 mg of NADP in triethanolamine buffer solution, reacted for 12 hours, and the conversion rate was 99% as detected by HPLC, heated and concentrated to a volume of 10 mL, filtered to get the filtrate, adjusted the pH to 12.0-12.5 with a 25% NaOH solution, and cooled the temperature in an ice-water bath to 0°C, heat preservation for 12 hours, and filter to obtain 1.7 g of the product with a content of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com