First liquid and second liquid of two-liquid mixing type and method for manufacturing printed wiring board

A printed wiring board and hybrid technology, which is applied in the fields of printed circuit manufacturing, printed circuit, printed circuit secondary treatment, etc., can solve the problems of poor storage stability and achieve excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

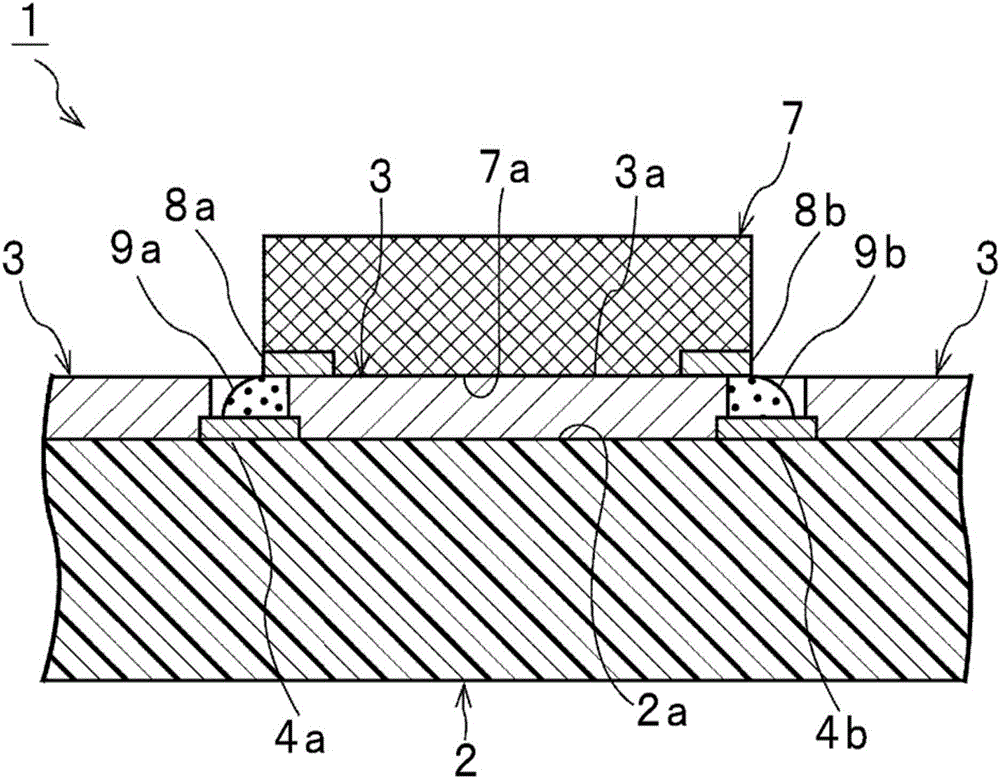

Image

Examples

Synthetic example 1

[0129] Put ethyl carbitol acetate as a solvent and azobisisobutyronitrile as a catalyst in a flask equipped with a thermometer, a stirrer, a dropping funnel, and a reflux condenser, and heat to 80° C. under a nitrogen atmosphere. A monomer obtained by mixing methacrylic acid and methyl methacrylate at a molar ratio of 30:70 was added dropwise over 2 hours. After the dropwise addition, the mixture was stirred for 1 hour, and the temperature was raised to 120°C. Then, cool down. Add glycidyl acrylate, the ratio of its molar weight to the total molar weight of the total monomer units of the obtained resin is 10, use tetrabutylammonium bromide as a catalyst, and heat at 100°C for 30 hours to make glycidyl acrylate Addition reaction with carboxyl group. After cooling, it was taken out from the flask to obtain a solution of carboxyl-containing resin containing 50% by weight (non-volatile matter) of solid content acid value 60mgKOH / g, weight average molecular weight 15000, and doub...

Embodiment 1

[0141] 15 g of the acrylic polymer obtained in Synthesis Example 1, 2 g of TPO (a photoradical generator, i.e. photopolymerization initiator, manufactured by BASF Japan), 30 g of CR-50 (titanium oxide, manufactured by Ishihara Sangyo Co., Ltd.), 30 g Ethyl carbitol acetate (diethylene glycol monoethyl ether acetate, manufactured by Diacel), 5g of FH105 (talc, manufactured by Fuji talc), and 1g of KS-7710 (complex type silicone oil, polydimethylsiloxane) Methylsiloxane, manufactured by Shin-Etsu Chemical Co., Ltd.), was mixed for 3 minutes with a mixer (Rentaro ARE-310, manufactured by Thinky Co., Ltd.), and then mixed with a triple roller to obtain a mixture. Then, the resulting mixture was defoamed for 3 minutes using ARE-310, thereby obtaining a first liquid.

[0142] 828 (bisphenol A type epoxy resin, manufactured by Mitsubishi Chemical Co., Ltd.), 5 g of DPHA (dipentaerythritol hexaacrylate), 5 g of FH105 (talc, manufactured by Fujitalc Co., Ltd.) and 10 g of CR-50 (titani...

Embodiment 2~9 and comparative example 1、2

[0145] Except that the types and compounding amounts of the materials used in the first liquid and the second liquid were changed as shown in the following Table 1, a two-liquid mixture having the first and second liquids was obtained in the same manner as in Example 1. Type first and second liquids (photosensitive composition before mixing).

[0146] (Evaluation)

[0147] (1) Storage stability

[0148] The first and second liquids obtained as above were put into a plastic container (manufactured by Kinki Container Co., Ltd., BHS-1200), left to stand at room temperature for 6 months, then, 2g of supernatant and The liquid at the bottom of the container was fired in a crucible at 550°C for 2 hours, and the ash content was calculated by the following formula.

[0149] Ash content (%) = liquid weight after firing / liquid weight before firing × 100

[0150] Based on the difference in ash content between the supernatant liquid and the liquid at the bottom of the container obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com