Nanocomposite loading carbon-coated SnO2 nano particles on graphene sheets and preparation method of nanocomposite

A nanocomposite material and nanoparticle technology, which is applied in the field of lithium battery anode materials with high energy storage density and cycle stability and its preparation, can solve problems such as weak charge conduction ability, and achieve easy mass production, good industrial production basis, The effect of simple preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

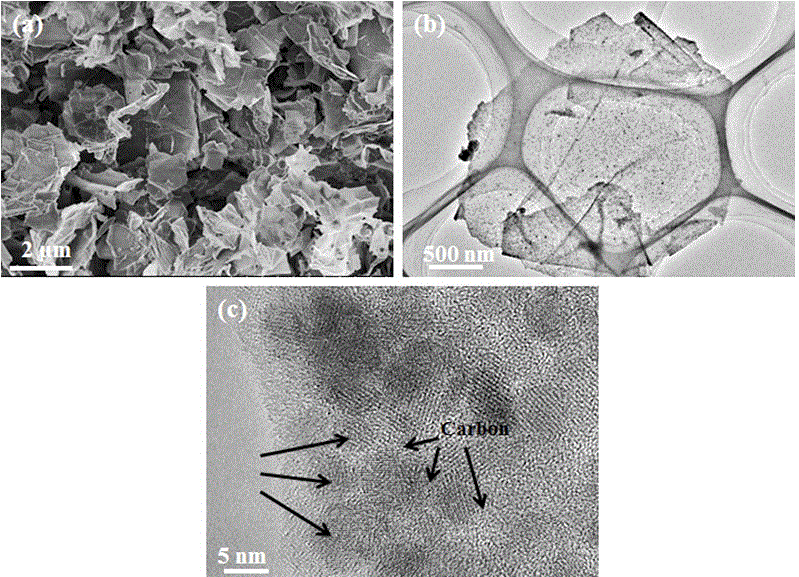

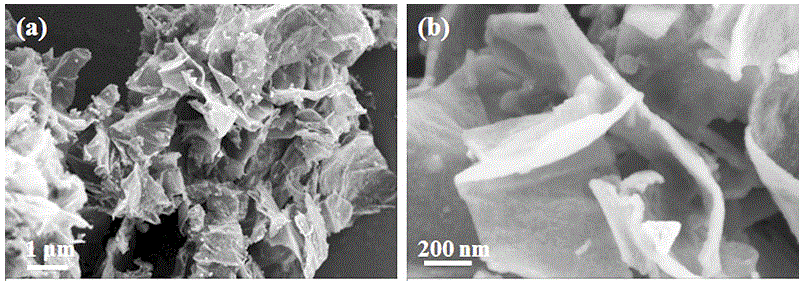

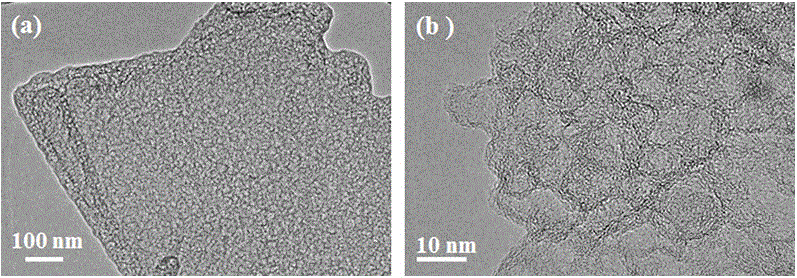

Image

Examples

Embodiment 1

[0028] (1) The graphene oxide (GO) prepared by redox method was dispersed in acetone to obtain the solvent dispersion of GO, and the concentration of GO was 2 mg / ml;

[0029] (2) Weigh 0.07 g of ferrocene and ultrasonically dissolve it in 5 ml of acetone, then add 5 ml of the GO dispersion prepared in step (1), sonicate for 30 min to disperse evenly, and then add 0.35 ml of hydrogen peroxide;

[0030] (3) Transfer the mixed liquid obtained in step (2) to an autoclave, and place it in an oven at 210°C for 12 h; after cooling down to room temperature naturally, take out the liquid and wash it by centrifugation with absolute ethanol for 3 times; then The reactant was dried in an oven at 60°C for 12 h;

[0031] (4) Take 0.5 g of the dried powder and place it in a tube furnace, heat it up to 500 °C under the protection of nitrogen, and keep it for 2 h to obtain the final nanocomposite material, which is denoted as graphene@Fe 3 o 4 @C;

[0032] (5) Weigh 0.25 g graphene@Fe 3 o4...

Embodiment 2

[0036] (1) The graphene oxide (GO) prepared by redox method was dispersed in acetone to obtain the solvent dispersion of GO, and the concentration of GO was 2 mg / ml;

[0037] (2) Weigh 0.07 g of ferrocene and ultrasonically dissolve it in 5 ml of acetone, then add 5 ml of the GO dispersion prepared in step (1), and ultrasonically disperse evenly for 30 min without adding hydrogen peroxide;

[0038] (3) Transfer the mixed liquid obtained in step (2) to an autoclave, and place it in an oven at 210°C for 12 h; after cooling down to room temperature naturally, take out the liquid and wash it by centrifugation with absolute ethanol for 3 times; then The reactant was dried in an oven at 60°C for 12 h;

[0039] (4) Take 0.5 g of the dried powder and place it in a tube furnace, heat it up to 500 °C under the protection of nitrogen, and keep it for 2 h to obtain the final nanocomposite material, which is denoted as graphene@Fe 3 o 4 @C;

[0040] (5) Weigh 0.25 g graphene@Fe 3 o 4 ...

Embodiment 3

[0044] (1) The graphene oxide (GO) prepared by redox method was dispersed in acetone to obtain the solvent dispersion of GO, and the concentration of GO was 2 mg / ml;

[0045] (2) Weigh 0.05 g of ferrocene and ultrasonically dissolve it in 5 ml of acetone, then add 5 ml of the GO dispersion prepared in step (1), sonicate for 30 min to disperse evenly, and then add 0.25 ml of hydrogen peroxide;

[0046] (3) Transfer the mixed liquid obtained in step (2) to an autoclave, and place it in an oven at 210°C for 12 h; after cooling down to room temperature naturally, take out the liquid and wash it by centrifugation with absolute ethanol for 3 times; then The reactant was dried in an oven at 60°C for 12 h;

[0047] (4) Take 0.5 g of the dried powder and place it in a tube furnace, heat it up to 500 °C under the protection of nitrogen, and keep it for 2 h to obtain the final nanocomposite material, which is denoted as graphene@Fe 3 o 4 @C;

[0048] (5) Weigh 0.25 g graphene@Fe 3 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com