Graphene airgel loaded lithium iron phosphate porous composite material and preparation method thereof

A technology of graphene airgel and porous composite materials, applied in the direction of electrical components, structural parts, battery electrodes, etc., can solve the problems of poor high-rate discharge performance, complicated process of hard template method, and limitation of large-scale application, and achieve high Excellent rate performance, improved lithium ion diffusion performance, and good electrolyte wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

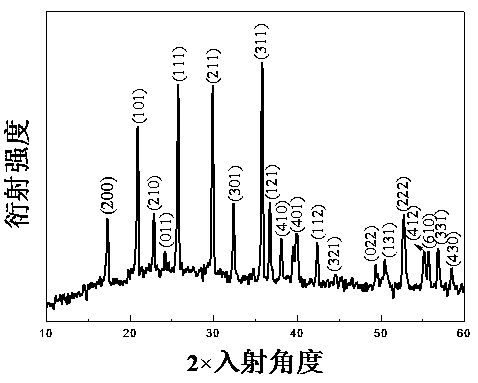

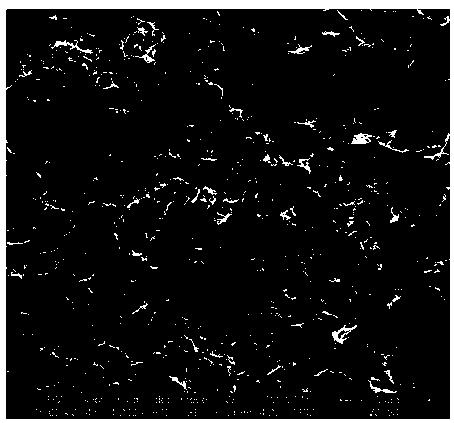

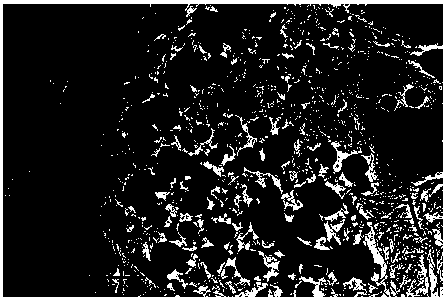

Image

Examples

Embodiment 1

[0027] A graphene airgel-loaded lithium iron phosphate porous composite material and a preparation method thereof. The preparation method described in this embodiment is:

[0028] 1) According to the concentration of graphene oxide aqueous solution is 2~3kg / m 3 , adding graphene oxide into deionized water and stirring for 1-2 hours to obtain solution I.

[0029] 2) According to the mass ratio of iron salt:graphene oxide is 1:0.2~0.3, add iron salt into solution I, stir for 0.5~1 hour, and obtain solution II.

[0030] 3) Then according to the material ratio of iron salt: phosphate: lithium salt is 1: 1: 2, phosphate and lithium salt are added to solution II in sequence, and stirred for 1-2 hours to obtain solution III.

[0031] 4) Move the solution Ⅲ to the reactor for hydrothermal reaction, the temperature of the hydrothermal reaction is 175-185°C, and the time of the hydrothermal reaction is 11.5-12.5 hours; the product after the hydrothermal reaction is washed with distill...

Embodiment 2

[0036] A graphene airgel-loaded lithium iron phosphate porous composite material and a preparation method thereof. The preparation method described in this embodiment is:

[0037] 1) According to the concentration of graphene oxide aqueous solution is 3~4kg / m 3 , adding graphene oxide into deionized water and stirring for 1-2 hours to obtain solution I.

[0038] 2) According to the mass ratio of iron salt:graphene oxide is 1:0.1~0.2, add iron salt into solution I, stir for 0.5~1 hour, and obtain solution II.

[0039] 3) Then according to the material ratio of iron salt: phosphate: lithium salt is 1: 1: 2, phosphate and lithium salt are added to solution II in sequence, that is, stirred for 1 to 2 hours to obtain solution III.

[0040] 4) Move the solution Ⅲ to the reactor for hydrothermal reaction, the temperature of the hydrothermal reaction is 175-185°C, and the time of the hydrothermal reaction is 11.5-12.5 hours; the product after the hydrothermal reaction is washed with...

Embodiment 3

[0045] A graphene airgel-loaded lithium iron phosphate porous composite material and a preparation method thereof. The preparation method described in this embodiment is:

[0046] 1) According to the concentration of graphene oxide aqueous solution is 4~5kg / m 3 , adding graphene oxide into deionized water and stirring for 1-2 hours to obtain solution I.

[0047] 2) According to the mass ratio of iron salt:graphene oxide is 1:0.03~0.1, add iron salt into solution I, stir for 0.5~1 hour, and obtain solution II.

[0048] 3) Then according to the material ratio of iron salt: phosphate: lithium salt is 1: 1: 2, phosphate and lithium salt are added to solution II in sequence, and stirred for 1-2 hours to obtain solution III.

[0049] 4) Move the solution Ⅲ to the reactor for hydrothermal reaction, the temperature of the hydrothermal reaction is 175-185°C, and the time of the hydrothermal reaction is 11.5-12.5 hours; the product after the hydrothermal reaction is washed with distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com