Polyolefin multilayer microporous membrane and battery separator

A technology of microporous membrane and polyolefin, which is applied in the direction of secondary batteries, battery pack components, separators/films/diaphragms/spacers, etc., can solve the problems of increased shutdown temperature, and achieve the purpose of suppressing heat runaway and fire, Effects of excellent heat resistance, sufficient mechanical strength and shutdown characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

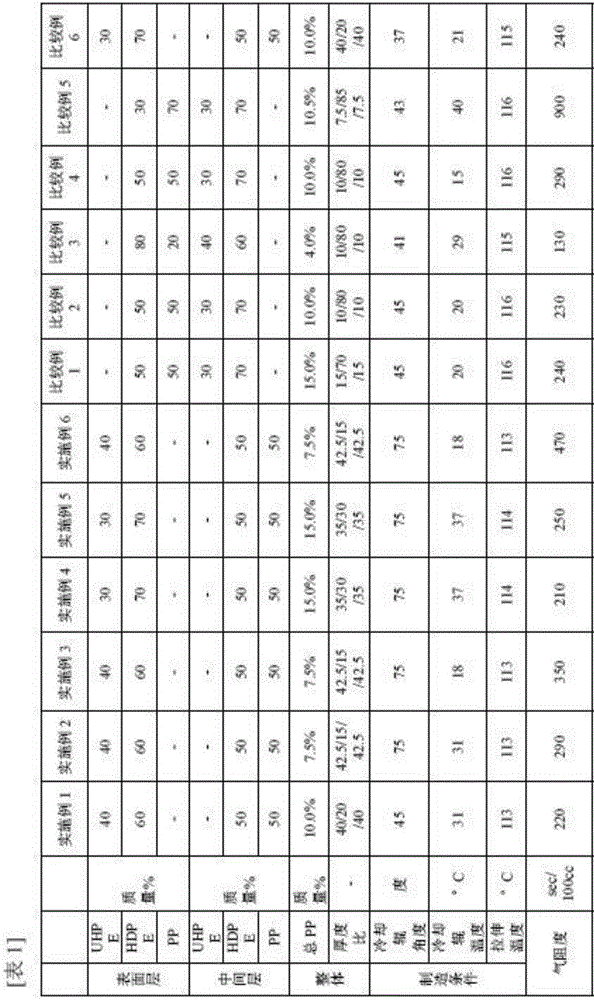

Embodiment 1

[0215] (1) Preparation of the first polyolefin solution

[0216] Pair by Mw is 2.0×10 6 The ultra-high molecular weight polyethylene (UHPE) is 40% by mass and Mw is 5.6×10 5 100 parts by mass of polyethylene-based resin composed of 60 mass% of high-density polyethylene (HDPE), mixed with tetrakis [methylene-3-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate ] 0.2 parts by mass of methane was used as an antioxidant to prepare a mixture.

[0217] 25 parts by mass of the obtained mixture was put into a strong mixing type twin-screw extruder, and 75 parts by mass of fluid paraffin [35cSt (40°C)] was supplied from the side feeder of the twin-screw extruder, Melt-kneading was performed at 250 rpm to prepare a first polyolefin solution.

[0218] (2) Preparation of the second polyolefin solution

[0219] Pair by Mw is 5.6×10 5 The high density polyethylene (HDPE) and Mw is 1.6×10 6 100 parts by mass of polyolefin resin composed of 50% by mass of polypropylene (PP), blended with te...

Embodiment 2

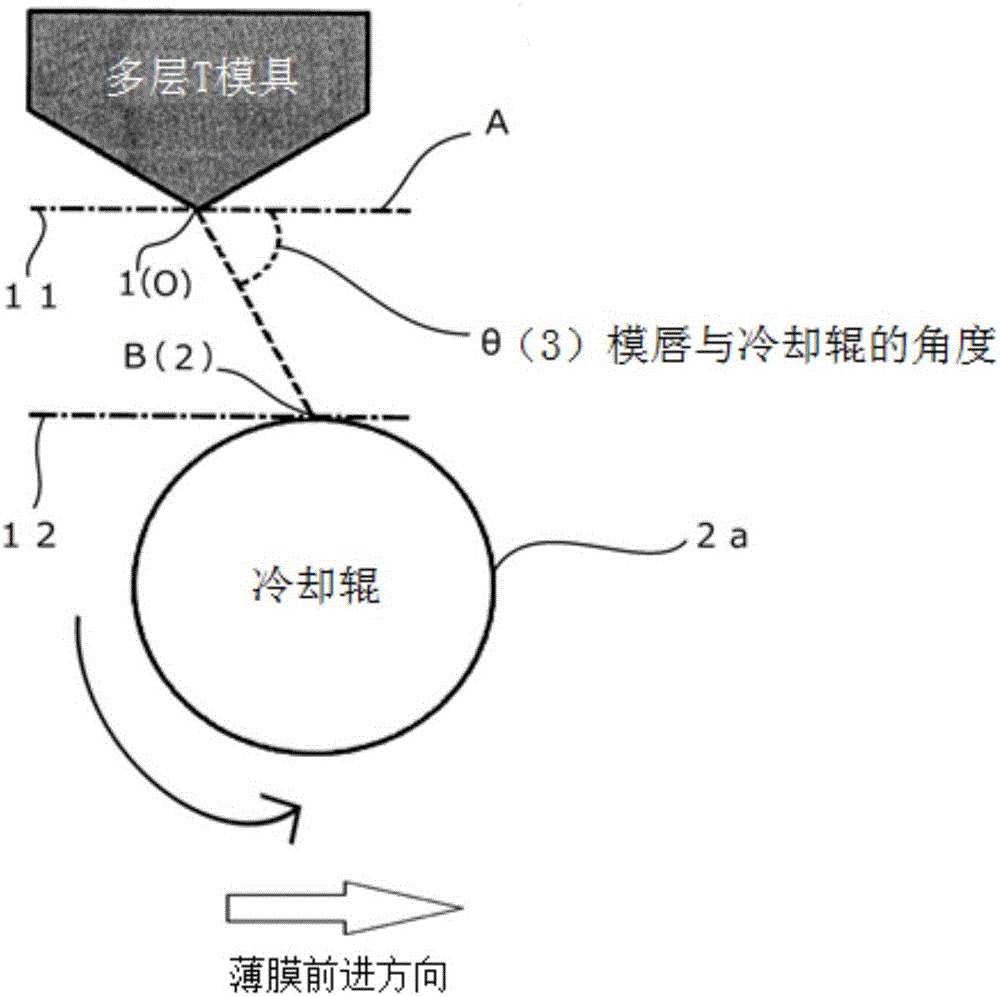

[0229] In addition to setting the thickness ratio of the polyolefin three-layer microporous film to 42.5 / 15 / 42.5, setting the angle θ to the cooling roll to 75 degrees, and re-stretching and heat-fixing in the TD direction at a temperature of 127°C. Except stretching 1.6 times, according to the same conditions as in Example 1, a polyolefin three-layer microporous membrane was prepared.

Embodiment 3

[0231] Except that the temperature of the cooling roll is set to 18°C, and the stretching and heat fixing are stretched 1.6 times in the TD direction at a temperature of 125°C, according to the same conditions as in Example 2, a polyolefin three-layer micro porous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| heat of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com