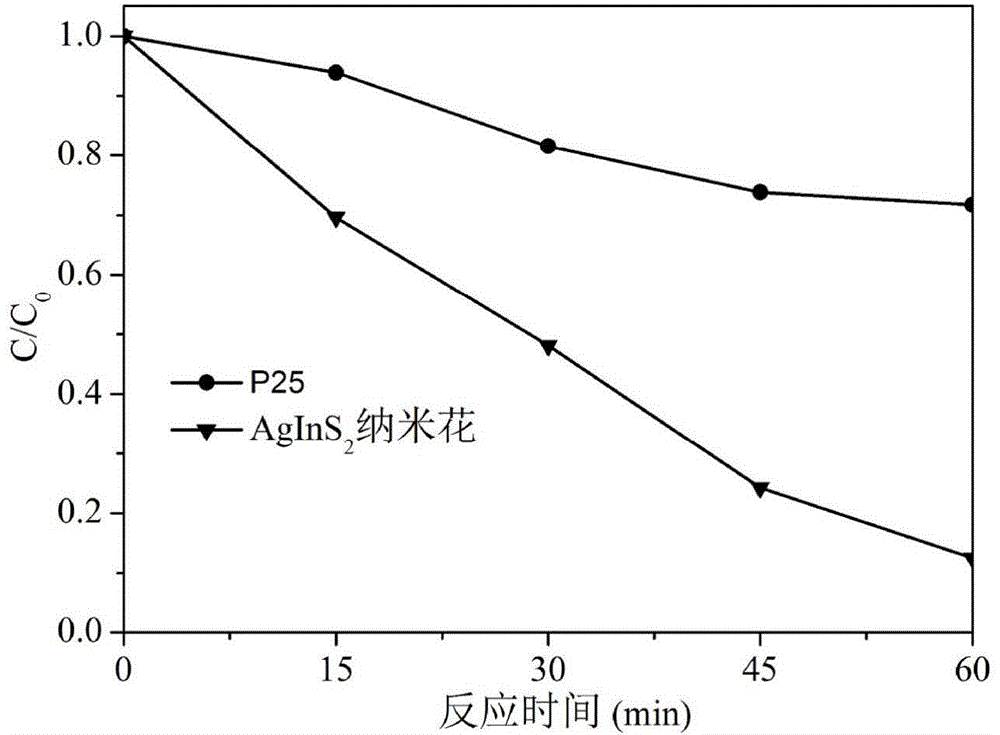

AgInS2 nanoflower having visible light photocatalytic oxidation and photocatalytic reduction capabilities, and preparation and applications thereof

A technology of photocatalytic oxidation and nanoflowers, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor stability, limited development, and easy photocorrosion of binary sulfides, and achieve Ease of operation, small band gap, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

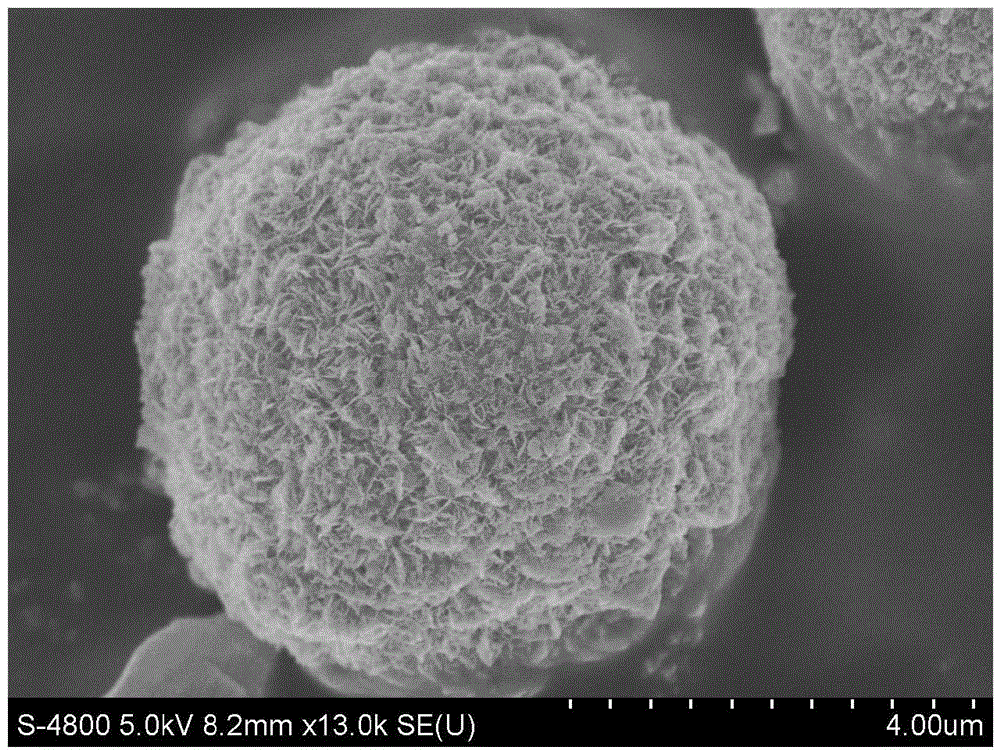

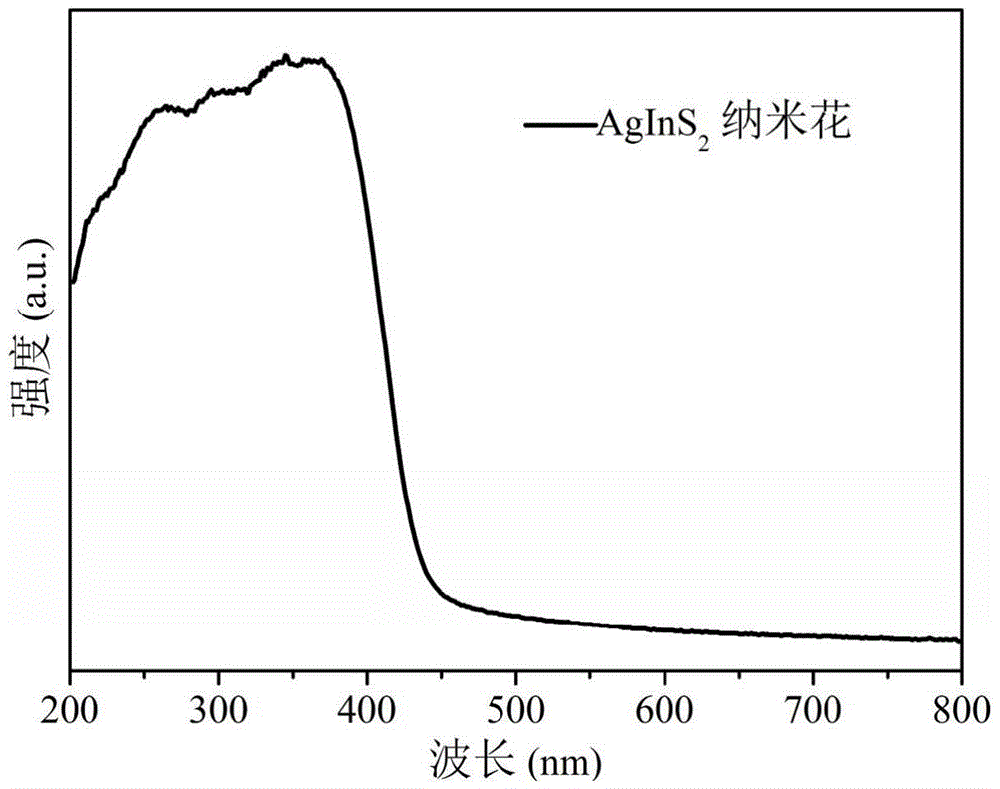

[0022] 0.2g AgNO 3 Dissolve in 96mL water to form AgNO 3 solution; 0.22g InCl 3 Add to AgNO 3 After mixing in the solution, add 0.19g of thiourea and stir for 30min to form a transparent and uniform solution. The solution was transferred to a 120mL autoclave lined with polytetrafluoroethylene, pressurized to 1.45atm, placed in an oven for hydrothermal reaction at 160°C for 12h, and cooled naturally to room temperature. Centrifuge and collect the brick-red precipitate at the bottom, wash with deionized water and then with absolute ethanol, and dry at 80 °C for 12 h to obtain AgInS 2 nanoflowers. from figure 1 AgInS can be clearly shown on 2 nanoflowers, from figure 2 As can be seen above, in the range of 350-550nm visible light, AgInS 2 Nanoflowers have strong absorption capacity.

Embodiment 2

[0024] 0.2g AgNO 3 Dissolve in 96mL ethanol to form AgNO 3 solution; 0.22g InCl 3 Add to AgNO 3 After mixing in the solution, add 0.19g of thiourea and stir for 30min to form a transparent and uniform solution. The solution was transferred to a 120mL autoclave lined with polytetrafluoroethylene, pressurized to 1.40atm, placed in an oven for hydrothermal reaction at 160°C for 12h, and cooled to room temperature naturally. Centrifuge and collect the brick-red precipitate at the bottom, wash with deionized water and then with absolute ethanol, and dry at 80 °C for 12 h to obtain AgInS 2 nanoflowers.

Embodiment 3

[0026] 0.2g AgNO 3 Dissolve in 96mL ethanol to form AgNO 3 solution; 0.22g InCl 3 Add to AgNO 3 After mixing in the solution, add 0.19g of thiourea and stir for 30min to form a transparent and uniform solution. The solution was transferred to a 120mL autoclave lined with polytetrafluoroethylene, pressurized to 1.32atm, placed in an oven for hydrothermal reaction at 120°C for 48h, and cooled to room temperature naturally. Centrifuge and collect the brick-red precipitate at the bottom, wash with deionized water and then with absolute ethanol, and dry at 80 °C for 12 h to obtain AgInS 2 nanoflowers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com