Recyclable, efficient, efficient, low-resistance, antibacterial and haze-preventing air filtration material

An air filter material and anti-smog technology, which is applied in the fields of filtration and separation, membrane filters, chemical instruments and methods, etc., can solve the problems of not being able to fully meet the requirements of high-efficiency filter materials, difficult to effectively filter sub-micron particles, and short service life , to achieve the effect of repeated reuse, increased antibacterial properties, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A recyclable, high-efficiency, low-resistance, antibacterial and anti-fog air filter material is prepared by the following method:

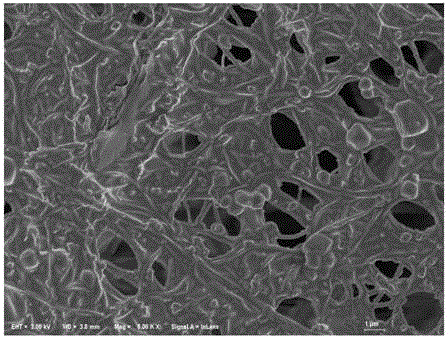

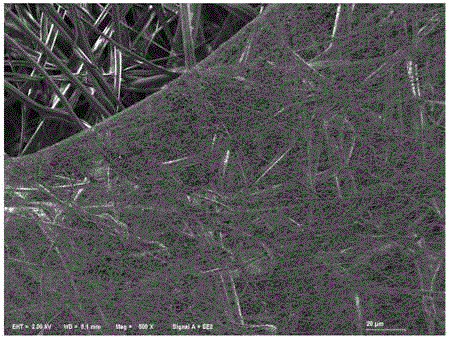

[0031] (1) Polyamide 66 is dissolved in a mixed solvent of formic acid and acetic acid (3:1), and the spinning solution (concentration 15%) is configured. Electrospinning parameters, voltage 18KV, propulsion volume 0.2mL / h, temperature 50°C, receiving distance 18cm, spinning time 30min, using PP melt-blown cloth as the base to prepare nanofibers composited on the substrate layer;

[0032] (2) Preparation of nano-silver particle solution: take silver nitrate of 0.019g, 0.019g sodium citrate, take silver nitrate as silver precursor, sodium citrate as reducing agent; Silver nitrate is added to deionized water earlier, oil Heating the bath to 120°C to boil the silver nitrate solution, adding sodium citrate solution under vigorous magnetic stirring, and reacting for 1 hour to obtain the nano-silver particle solution;

[0033] (3) Dilute hydroc...

Embodiment 2

[0036] A recyclable, high-efficiency, low-resistance, antibacterial and anti-fog air filter material is prepared by the following method:

[0037] (1) Dissolve polyamide 6 (PA6) in formic acid solvent, prepare spinning solution (concentration 13%), electrospinning parameters, voltage 12kV, propulsion volume 0.5mL / h, temperature 60°C, receiving distance 12cm, spinning Filament time 30min, using PP melt-blown cloth as the base to prepare nanofibers composited on the substrate layer;

[0038] (2) Preparation of nano silver particle solution: take silver nitrate of 0.008g, sodium citrate of 0.019g, sodium borohydride 0.014g, take silver nitrate as silver precursor, sodium citrate and sodium borohydride as reducing agent; First add silver nitrate and sodium citrate to deionized water, stir magnetically at room temperature to completely dissolve and form a colorless transparent liquid, then dissolve sodium borohydride in 5ml deionized water, add it to the colorless transparent liqui...

Embodiment 3

[0041] A recyclable, high-efficiency, low-resistance, antibacterial and anti-fog air filter material is prepared by the following method:

[0042] (1) Dissolve polyamide 610 in formic acid solvent, configure spinning solution (concentration 15%), electrospinning parameters, voltage 19KV, propulsion volume 0.3mL / h, temperature 50°C, receiving distance 18cm, spinning time 30min , using PP knitted fabric as the base to prepare nanofibers composited on the substrate layer;

[0043] (2) Preparation of nano-silver particle solution: take silver nitrate of 0.017g, 0.020g sodium citrate, take silver nitrate as silver precursor, citric acid as reducing agent; Silver nitrate is added to deionized water earlier, oil bath Heat to 120°C to boil the silver nitrate solution, add sodium citrate solution under the condition of vigorous magnetic stirring, and obtain the nano-silver particle solution after 0.5h of reaction;

[0044] (3) Use dilute hydrochloric acid to adjust the pH=7 of the nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com