Low-temperature-resistant rare earth ore flotation collecting agent and preparation method and application thereof

A rare earth ore and collector technology, used in flotation, solid separation, etc., can solve the problems of poor selectivity and collection performance of collectors, restricting the development and utilization of rare earth ore, and poor low temperature resistance of collectors. Achieve the effect of reducing capital investment and energy consumption, mature production technology, and good flotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

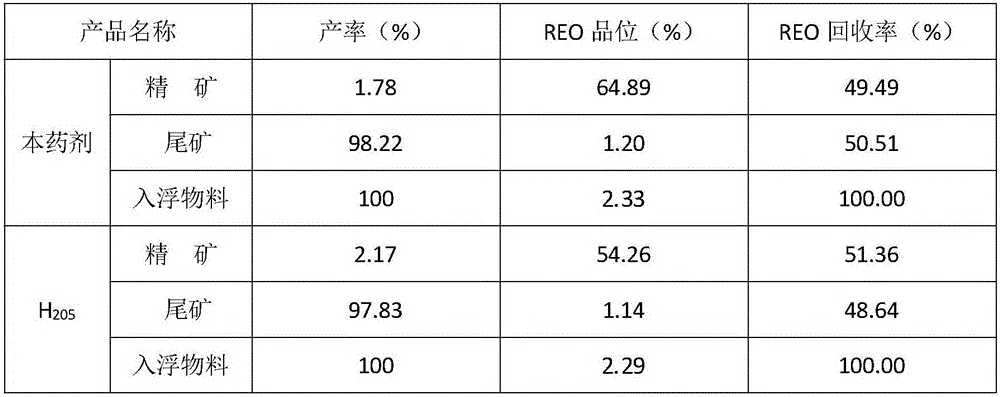

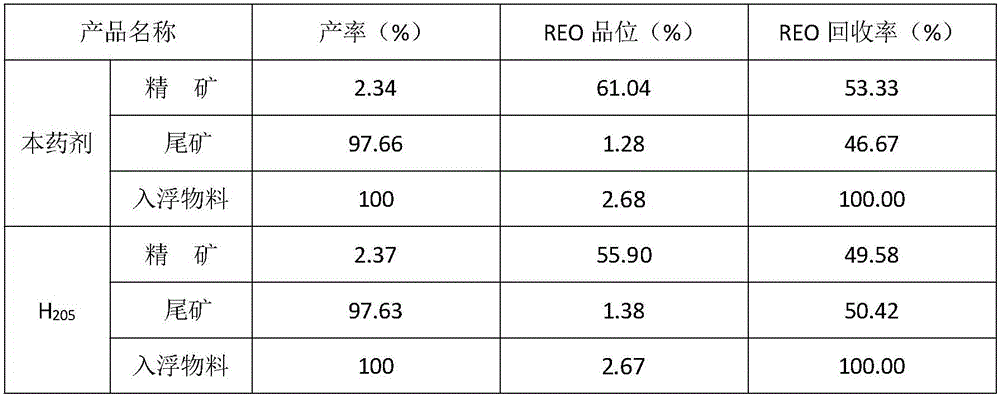

Embodiment 1

[0034] The rare earth ore collector is composed of the following mass ratio materials: 30 parts of salicylaldoxamic acid, 50 parts of C 5~7 Hydroxamic acid, 10 parts o-hydroxynaphthalene hydroxamic acid, 8 parts coconut oleic acid, 2 parts OP-10.

[0035] Will C 5~7 Add 50kg of fatty acid, 10kg of o-hydroxynaphthoic acid and 20kg of dimethyl carbonate into the enamel reaction kettle, stir evenly, add 8.0kg of concentrated sulfuric acid (accounting for 10% of the total weight), install the cooling reflux device, and start the heating reflux reaction After 20 hours, the product obtained liquid mixed carboxylate after centrifugation, and discarded after the paste treatment; 10kg of the liquid mixture (carboxylate) of gained was obtained, salicylaldehyde 5kg and 15% hydroxylamine sulfate aqueous solution containing 16.0kg hydroxylamine sulfate Add it into the enamel reaction kettle, add dropwise the mass fraction of 35% sodium hydroxide aqueous solution while stirring, keep the p...

Embodiment 2

[0040] This rare earth ore collector is composed of the following mass ratio materials: 35 parts of salicylaldoxamic acid, 40 parts of C 5-7 Hydroxamic acid, 15 parts of naphthalene hydroxamic acid, 7.5 parts of coconut oleic acid, 2.5 parts of OP-10.

[0041] Will C 5-7 Add 40kg of fatty acid, 15kg of naphthoic acid and 25.0kg of dimethyl carbonate into the enamel reaction kettle, stir evenly, add 12kg of concentrated sulfuric acid, install the cooling reflux device, start heating and reflux reaction for 15 hours, and the product is centrifuged to obtain liquid The liquid in the upper phase is a mixed carboxylate, and the lower paste is discarded after treatment; 10kg of the resulting liquid mixed carboxylate is added, and then 6.25kg of salicylaldehyde and 15.9kg of 20% aqueous solution of hydroxylamine sulfate are added to the enamel. In the reactor, add dropwise the mass fraction of 40% sodium hydroxide aqueous solution while stirring, keep the pH value in the reactor not...

Embodiment 3

[0046] This rare earth ore collector is composed of the following mass ratio materials: 40 parts salicylic hydroxamic acid, 32.5 parts C 5-7 Alkyl hydroxamic acid, 7.5 parts o-hydroxynaphthalene hydroxamic acid, 9 parts coconut oleic acid, 1 part OP-10.

[0047] Will C 5-7 Add 32.5kg of fatty acid, 7.5kg of o-hydroxynaphthoic acid and 30kg of dimethyl carbonate into the enamel reaction kettle. After stirring evenly, add 9.0kg of concentrated sulfuric acid, install a cooling reflux device, and heat and reflux for 10 hours. Obtaining the upper layer liquid of the liquid phase after layering is a mixed carboxylate, and the lower floor paste is discarded after processing; get 10kg from the liquid mixed carboxylate of gained, then add 8kg salicylaldehyde and 18.6kg hydroxylamine sulfate containing 15% Hydroxylamine sulfate aqueous solution is added to the enamel reaction kettle, and the mass fraction is 50% sodium hydroxide aqueous solution is added dropwise while stirring, the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com