Preparation technology of sugarcane fruit vinegar

A preparation process, the technology of sugarcane fruit vinegar, which is applied in the field of food processing, can solve the problems of low value of sugarcane juice, etc., and achieve the effects of strong alcohol production capacity, loose fermentation conditions, and simple brewing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation technology of a kind of sugarcane fruit vinegar of the first chapter, comprises the steps:

[0030] (1) Preparation of sugarcane juice

[0031] Fresh sugarcane is pressed to obtain sugarcane juice;

[0032] (2) Alcoholic fermentation

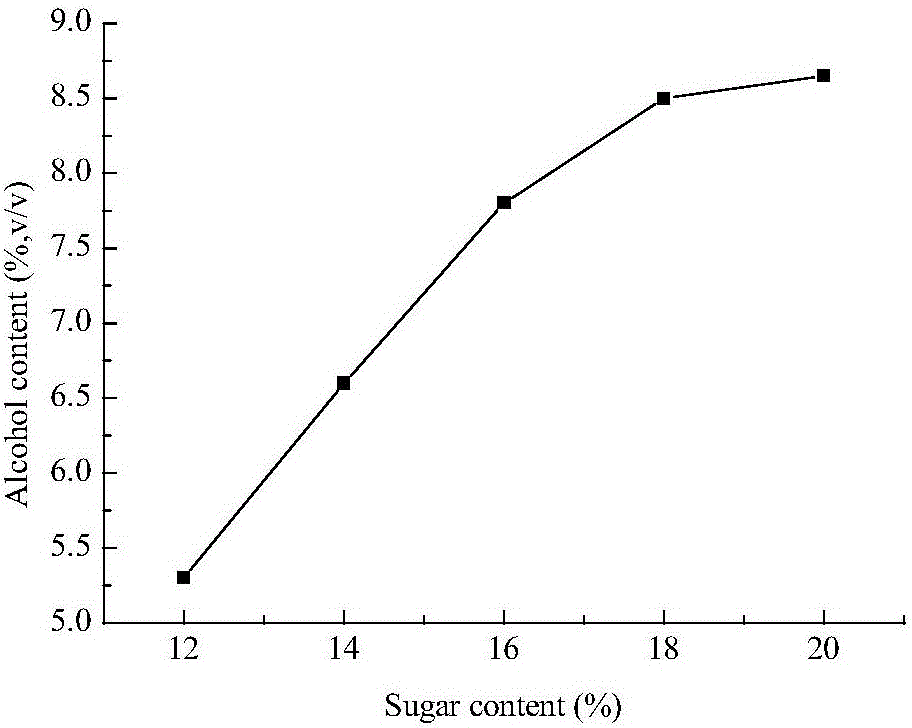

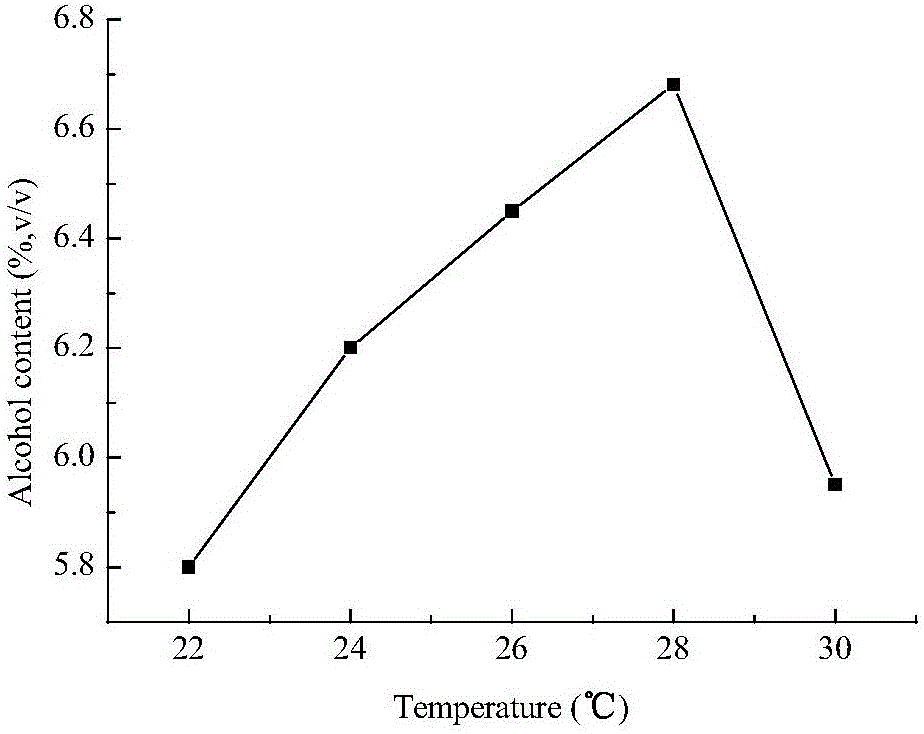

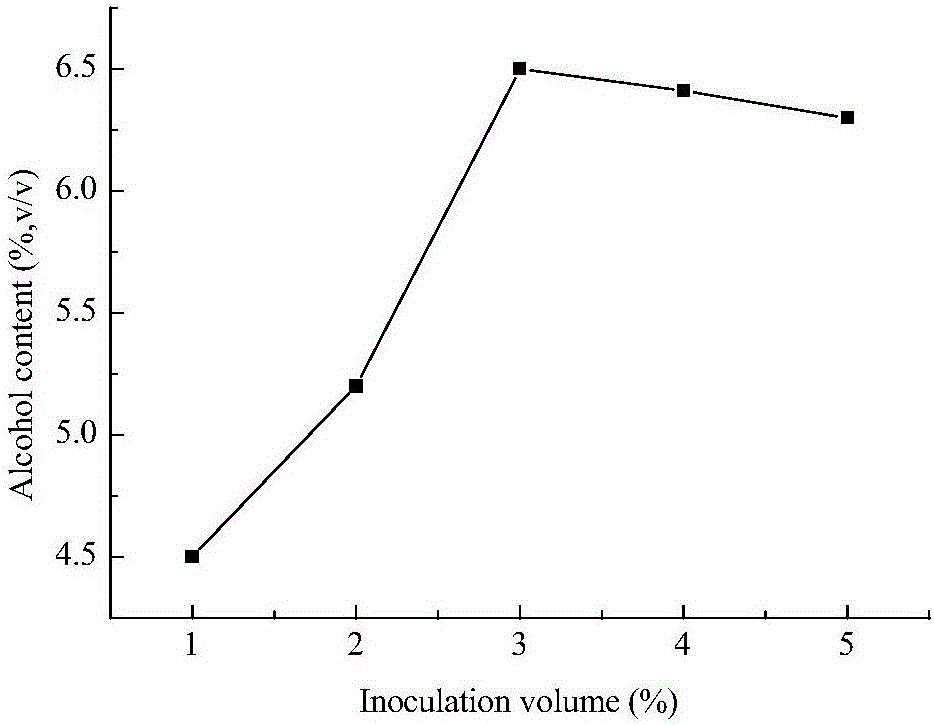

[0033] Use sucrose to adjust the sugar content of sugarcane juice to 17-19%, use citric acid and calcium carbonate to adjust the pH value of sugarcane juice to 4.4-4.7, after the adjustment is completed, sterilize under high temperature and high pressure and cool to room temperature, and then insert it under aseptic operation The weight percentage of the fermentation material is 2.5-3.5% of Saccharomyces cerevisiae, and it is placed under the condition of 27-28°C for anaerobic fermentation for 3-4 days to obtain sugarcane fruit wine;

[0034] (3) Acetic acid fermentation

[0035] Use sucrose to regulate the sugar content of sugarcane fruit wine to 5.5~6.5%, use citric acid and calcium carbonate to regulate the pH value ...

Embodiment 2

[0206] A kind of preparation technology of sugarcane fruit vinegar, comprises the steps:

[0207] (1) Preparation of sugarcane juice

[0208] Fresh sugarcane is pressed to obtain sugarcane juice;

[0209] (2) Alcoholic fermentation

[0210] Use sucrose to adjust the sugar content of sugarcane juice to 19%, use citric acid and calcium carbonate to adjust the pH value of sugarcane juice to 4.7, after the adjustment is completed, sterilize at high temperature and high pressure and cool to room temperature, then insert the fermentation material weight percentage under aseptic operation 3.5% Saccharomyces cerevisiae, placed in anaerobic fermentation at 28°C for 4 days to obtain sugarcane fruit wine;

[0211] (3) Acetic acid fermentation

[0212] Use sucrose to adjust the sugar content of the sugarcane wine to 6.5%, use citric acid and calcium carbonate to adjust the pH value of the sugarcane wine to 5.5, use sterile water and alcohol to adjust the alcohol content of the sugarcan...

Embodiment 3

[0214] A kind of preparation technology of sugarcane fruit vinegar, comprises the steps:

[0215] (1) Preparation of sugarcane juice

[0216] Fresh sugarcane is pressed to obtain sugarcane juice;

[0217] (2) Alcoholic fermentation

[0218] Use sucrose to adjust the sugar content of sugarcane juice to 17%, use citric acid and calcium carbonate to adjust the pH value of sugarcane juice to 4.4, after the adjustment is completed, sterilize at high temperature and high pressure and cool to room temperature, then insert the fermentation material weight percentage under aseptic operation 2.5% Saccharomyces cerevisiae, placed in anaerobic fermentation at 27°C for 3 days to obtain sugarcane fruit wine;

[0219] (3) Acetic acid fermentation

[0220] Use sucrose to adjust the sugar content of sugarcane wine to 5.5%, use citric acid and calcium carbonate to adjust the pH value of sugarcane wine to 5.0, use sterile water and alcohol to adjust the alcohol content of sugarcane wine to 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com