Method and device for producing energy substance nitrous oxide by denitrification

A technology for nitrous oxide and energy production, which is applied in the direction of using microorganisms, enzymatic/microbiological devices, biomass post-treatment, etc., can solve the problems of slow reaction rate, achieve simple production process, and realize waste recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

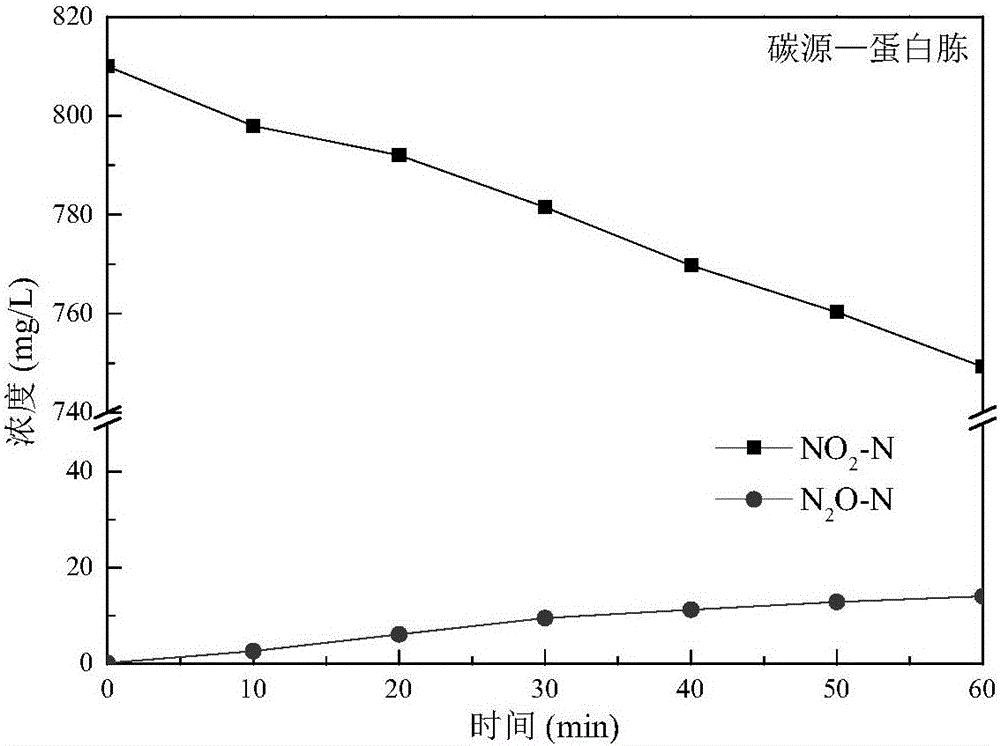

experiment example 1

[0039] (1) Microbial domestication process

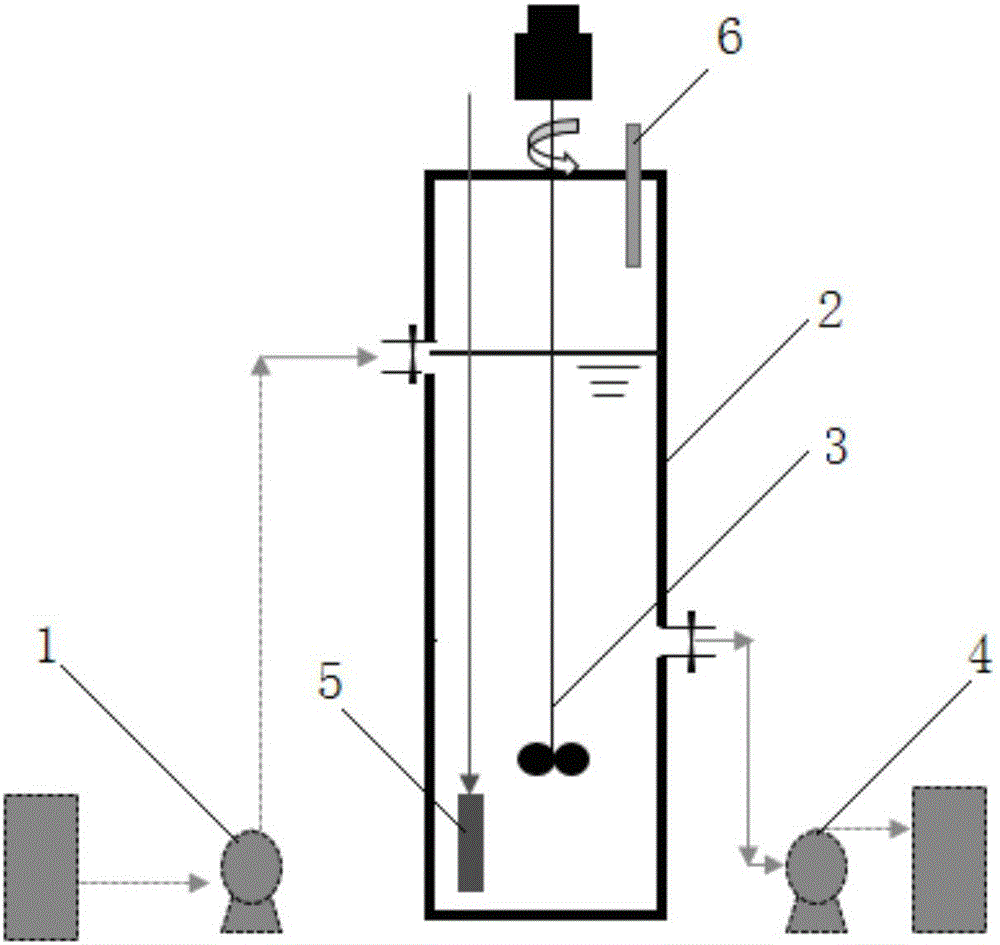

[0040] Two cylindrical plexiglass SBR reactors (sequencing batch reactors) with a height of 30 cm, a diameter of 10 cm, and an effective volume of 2000 mL were used to domesticate denitrifying bacteria. The operating cycle of the two SBR reactors is 4 hours, and the operating temperature is 26°C. 200mL of sludge is discharged every day, and the controlled sludge age (SRT) is 10 days. The SBR operation cycle includes 160min anoxic stirring (including 10min water inflow), 20min aerobic, 45min static sedimentation and 15min water outlet / idle. In each cycle, the water intake is 1L, the water output is 1L, and the hydraulic retention time (HRT) is 8h. The hydraulic retention time is the average residence time of sewage in the reactor. In this process, the reactor is 2L, and the water in and out is 1L in each cycle, so the residence time of sewage in the reactor is equivalent to two cycles, that is, 8h. The aerobic reaction stage is a...

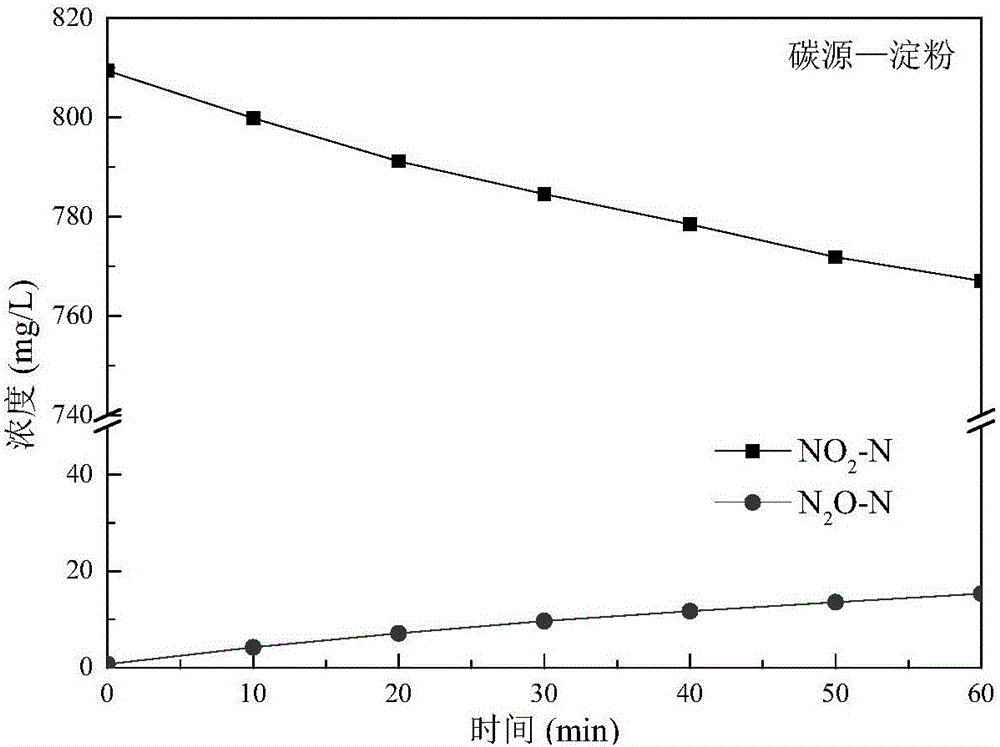

experiment example 2

[0046] (1) Microbial domestication process

[0047] A cylindrical plexiglass SBR reactor with a height of 30 cm, a diameter of 10 cm, and an effective volume of 2000 mL was used to domesticate denitrifying bacteria. The operation cycle of the SBR reactor is 4h, and each cycle includes: 160min anoxic stirring (including 10min water inflow), 20min aerobic, 45min static settlement and 15min water outlet / idle. In each cycle, the water intake is 1L, the water output is 1L, and the hydraulic retention time (HRT) is 8h. Discharge 200mL of sludge at the aerobic end of a specific cycle every day, and control the sludge age (SRT) for 10 days. In the aerobic reaction stage, a microporous aerator was used for aeration, and the water inflow and drainage of the reactor was realized by controlling the opening and closing of the peristaltic pump by a timer, and the reactor was domesticated at 26°C for a long time. The influent carbon source of the reactor is glucose, and the influent COD co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com