Method for chemically plating high-phosphorus nickel-phosphorus alloy

A technology of electroless nickel plating and high-phosphorus nickel, which is applied in the field of material science, can solve the problem of high plating cost and achieve the effect of increasing the deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

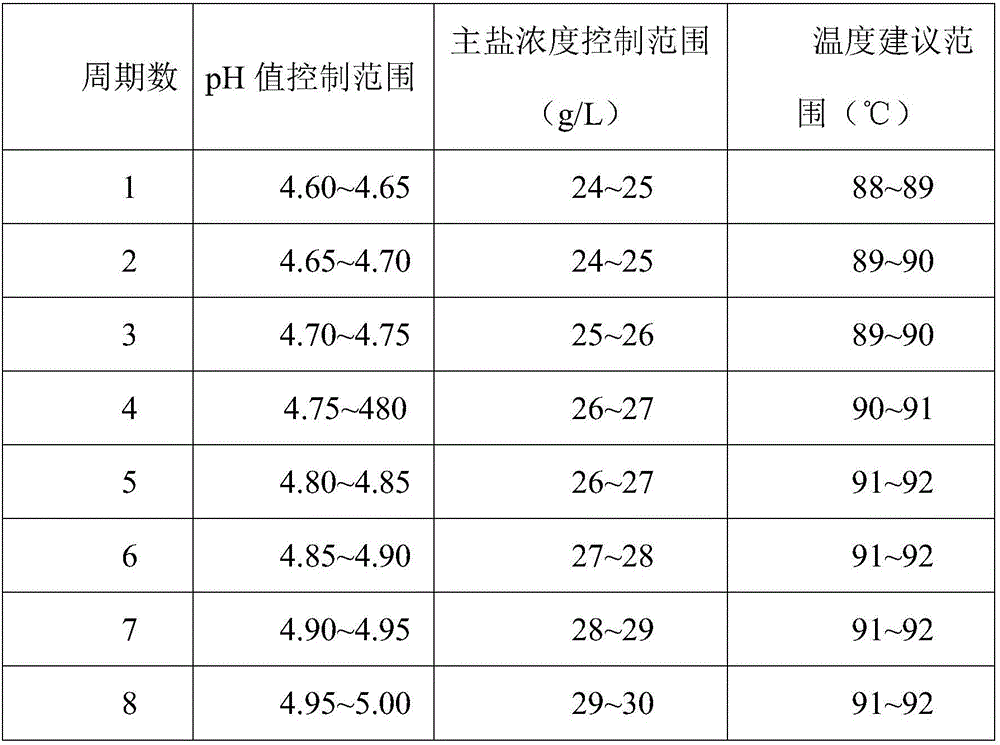

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 of the present invention: the method for chemically plating high phosphorus nickel-phosphorus alloy,

[0021] 1. Liquid preparation and tank preparation method

[0022] (1) Preparation of liquid A (take the preparation of 50L as an example)

[0023] Dissolve 12.5kg of nickel sulfate with about 35L of pure water. After the dissolution, add 6.5g of citric acid, 0.75g of benzotriazole, 0.35g of benzimidazole, 0.875g of PPS, and 0.25g of OP-10 under stirring. After stirring and mixing evenly, set the volume to 50L.

[0024] (2) Preparation of liquid B (calculated based on the preparation of 50L)

[0025] Dissolve 8.0kg of sodium hypophosphite with about 35L of pure water. After the dissolution, add 3.6kg of crystalline sodium acetate, 2.125kg of citric acid, 1.125g of benzotriazole, 0.575g of benzimidazole, and 3.3125g of PPS under stirring. OP-10 1.125g, stir well and mix evenly, then dilute to 50L.

[0026] (3) Preparation of liquid C (for addition, calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com